News

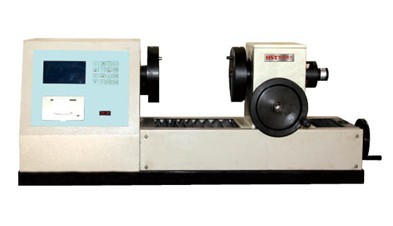

Characteristics and applications of microcomputer-controlled electro-hydraulic servo steel strand test machine

Release time:2019-06-19 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The core components of the servo control oil source of the microcomputer-controlled electro-hydraulic servo steel strand tester are all imported original devices, with stable performance, and have protection functions such as overload, overcurrent, overvoltage, upper and lower displacement limits and emergency stops. The built-in controller based on PCI technology ensures that the tester can realize closed-loop control of parameters such as test force, sample deformation and beam displacement, and can realize tests such as constant-speed test force, constant-speed displacement, constant-speed strain, constant-speed load cycle, and constant-speed deformation cycle. Various control modes can be switched smoothly. Below we will analyze the characteristics and applications of microcomputer-controlled electro-hydraulic servo strand test machines.

When the test of the microcomputer-controlled electro-hydraulic servo strand tester is completed, it can manually or automatically return to the initial test position at high speed, realizing automatic shifting, zeroing, calibration and storage of physical zeroing, gain adjustment and test force measurement. There is no analog adjustment link, and the control circuit is highly integrated. (6) The electrical control circuit refers to international standards, complies with the national electrical standards of the test machine, has strong anti-interference ability, ensuring the stability of the controller and the accuracy of the experimental data. The microcomputer-controlled electro-hydraulic servo steel strand test machine has a network transmission interface, which can transmit, store, print and record data and print network transmission and printing, and can be connected to the internal LAN of the enterprise or the Internet network. The main functional characteristics of the software are described. The measurement and control software is used to control the electro-hydraulic servo hydraulic test machine for microcomputer, conduct various metal and non-metal tests, and complete various functions such as real-time measurement and display, real-time control, data processing, and result output in accordance with the corresponding standards.

(1) Separate permission management. Operators of different levels have different operating permissions, and the operable menus and other contents are also different. This makes ordinary operators simple, convenient and fast to operate, and effectively protect the system;

(2) Real-time measurement and display of test force and peak, displacement, deformation and other signals; real-time acquisition and control under NT mode platforms such as Win2000 and WinXP; and timed and high-speed sampling are realized;

(3) Real-time screen display of various test curves such as load-deformation, load-displacement, etc., can be switched to observe at any time, making it easy to enlarge and reduce the curve;

(4) Computer storage, setting, loading and other functions with test parameters. Zero adjustment, calibration and other operations are carried out from the software. Each parameter can be easily stored and transferred, so that a host can be easily switched when multiple sensors are provided, and there is no number limit;

(5) Supports a variety of control methods, including open-loop constant-speed displacement, constant-speed force, constant-speed stress and other closed-loop control methods; and a standard reference curve is given during the operator's debugging of closed-loop parameters, so that the user can actually observe the impact of each parameter on the closed-loop effect.

(6) It has an intelligent setting expert system for testing process control mode, and is provided to professional users with automatic programmable programmers. Users can flexibly combine multiple control methods and control speeds according to actual needs, according to the rules, and prepare control programs that suit their needs. The measurement and control software will automatically control the test process according to the user settings.

(7) Use human-computer interaction to analyze data. The processing method meets the requirements of widely used standards, and can automatically calculate various performance parameters such as elastic modulus, yield strength, and specified non-proportional extension strength. It can also manually intervene in the analysis process to improve the accuracy of the analysis; other data processing can also be carried out according to the standards provided by the user.

(8) The test data is stored in text files to facilitate user query, and to reprocess the test data using any general commercial reports and word processing software, while also facilitating the data transmission online;

(9) The data curves of the entire test process can be recorded and saved, and the demonstration function can be used to realize the reproduction of the test curve. Curve superposition comparison can also be performed, which is convenient for comparison and analysis; (10) The test report can be printed in the format required by the user. Users can choose to report the basic information, test results and test curve contents to meet various needs;

(11) Digital zeroing and automatic calibration of test force and deformation are realized, which facilitates operation and improves the reliability of the machine. Various parameter system settings are stored in file form for easy storage and recovery.

The above is the characteristics and applications of the microcomputer-controlled electro-hydraulic servo steel strand tester that we have introduced to you. I hope the brief introduction above can be helpful to you. Dear customers: Our company has other products. You can call our service hotline through the web page to learn more about the product details. Fine and beautiful service is our pursuit. New and old customers are welcome to purchase their favorite products with confidence. We will serve you wholeheartedly!

Recommended productsPRODUCTS