News

Spring tension testing machines can be divided into several categories, what are their respective characteristics [Information]

Release time:2019-08-21 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The spring tension test machine can also be a spring tension test machine, a spring test machine, etc. The spring tension test machine can test and analyze the tension, pressure, displacement, stiffness and other strengths of the spring tension test machine, such as tension springs, pressure springs, disc springs, tower springs, leaf springs, clamp springs, leaf springs, composite springs, gas springs, mold springs, special-shaped springs, etc. Spring tension machines can be divided into three types. The following is an introduction to the characteristics of the three types.

1. Manual spring tester

1. The load measurement is digitally displayed, which overcomes the reading error of the human eye. The spring tester removes the displacement caused by deformation of the load sensor, making the displacement accurate. Easy to use, efficient, high precision, stable performance and other features.

2. Test force display: Digital display of digital tube, with upper and lower limit sorting function, outputting force value through the sensor.

3. Displacement display: The displacement scale output displacement; the accuracy is 0.01mm.

4. Loading method: manual loading, fast and convenient, with positioning device for quick sorting.

5. Overload protection: software protection and mechanical protection, the controller makes a sound when the force value is overloaded.

6. It is conducive to batch inspection of spring production lines; there are manual mode and automatic mode.

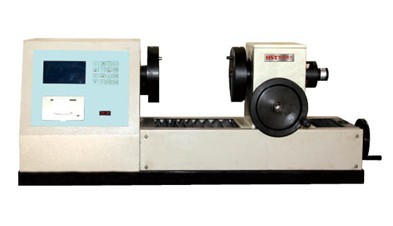

2. Automatic spring tension testing machine

1. Use high-precision, fully digital speed control system and precision speed reduction mechanism to drive the precision lead screw pair for testing, achieving large-scale adjustment of test speed, low noise during the test process, and stable operation

2. Touch operation mode, LCD display in real time, the display interface can display the test method selection interface, and has four functions: positioning and shift measurement force value, fixed deformation measurement force value, constant force value measurement displacement, and constant force value measurement deformation, to achieve all-round detection of spring measurement.

3. It can adjust the speed and slow lifting of the beam during style clamping, and has overload protection function (software protection and mechanical protection). Overload means that the machine will automatically shut down.

4. Realize the functions of storing, analyzing, printing and displaying calculation data.

5. The repeatability error is very small; suitable for random inspection.

6. Automatic machines have the functions of fast feeding and slow acquisition; they can achieve accurate acquisition of displacement point force values.

3. Microcomputer-controlled spring tension test machine

1. Tensile test: Perform tensile test on various tensile springs; Compression test: Perform compression test on various compression springs.

2. Measurement method: measure the force value by deformation, measure the force value by height, measure the deformation by force value, measure the height by force value.

3. Batch test: For samples with the same parameters, they can be completed in sequence after setting them once; batch inspection; no separate parameters are required.

4. Test software: Chinese WINDOWS interface, menu prompts, and mouse operation.

5. Display method: The data and curves are displayed dynamically with the test process; changes in the spring can be observed during the experiment; it is more intuitive than the first two processes.

6. Four types of curves: force value-displacement curve, force value-deformation curve, displacement-time curve, deformation-time curve.

7. Process implementation: The test process, measurement, display and analysis are all completed by the microcomputer.

8. Automatic saving: After the test is over, the test data and curves are automatically saved. The previous data can be queried in the later stage without recording it separately.

9. Test report: Reports can be prepared and printed in the format required by the user.

10. Suitable for random inspections of colleges and quality inspection departments.

Recommended productsPRODUCTS