News

Maintenance method for tensile testing machine not used for a long time and details that need to be paid attention to during work

Release time:2019-09-04 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

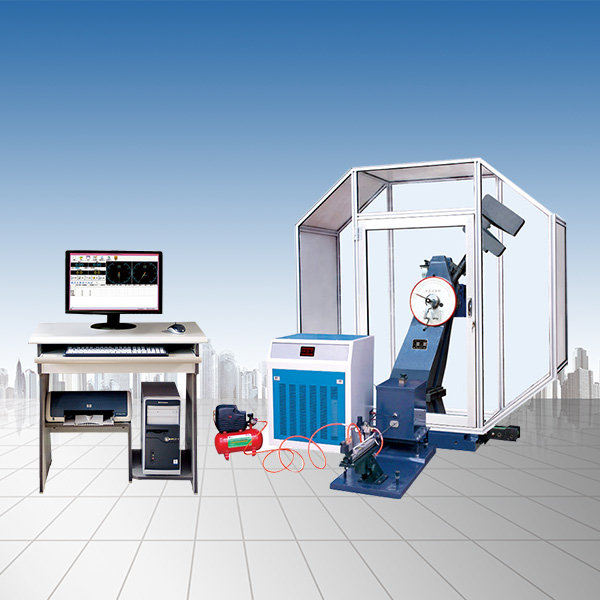

Tensile testing machine is also known as universal material testing machine. The universal testing machine is a mechanical after-force test machine used for mechanical properties such as static loading, tensile, compression, bending, shearing, tearing, peeling, etc. for various materials. It is suitable for the development of various physical and mechanical properties of plastic sheets, pipes, special profiles, plastic films, rubber, wires, cables, steel, glass fiber and other materials. The editor will introduce to you the maintenance method of the tensile testing machine that is not used for a long time and the details that need to be paid attention to when working.

1. Maintenance method for tensile testing machine not used for a long time

1. Apply anti-rust oil when the tension tester fixture is not in use to avoid rust affecting the test results;

2. Check whether the instrument is leaking oil regularly, and change the combination pad or sealing ring if there is abnormal situation;

3. Regularly replace the filter element, oil suction filter and hydraulic oil;

4. Clean the jaws regularly to keep them clean;

5. Check the screws at the jaws of the tension test machine regularly and tighten them in time if they are loose;

6. Check the transmission status of the sprocket regularly. If it is loose and tighten again, it will affect the test results and the operation of its parts;

7. The interface on the plug-in and unplug the controller must be turned off, which corresponds one by one. If the interface is plugged in incorrectly, it will cause damage to the machine;

2. Details that need to be paid attention to when using the tensile tester

1: Overload and overspeed operations will only cause death damage to the tensile tester and will also affect the results of future experiments. Therefore, we should eliminate such faulty operations;

2: Try not to place objects with high weight and high hardness around the tensile tester to prevent hard objects from colliding with the lifting screw;

3: The clamp of the tension machine must proceed smoothly when moving up and down to prevent friction with the machine itself. Before each experiment, you must check the tightness of the clamp screws;

4: When replacing fixtures, you must select the correct fixtures to prevent them from affecting the results of the experiment;

5: The connection process between the microcomputer and the tensile tester must be carried out according to the instructions, and the used operators may make the correct connection;

6: When printing the results obtained by the tensile test machine, check whether the printer is available;

7: After the application is completed, remove the fixture and the object to be tested to facilitate the next use;

8: In the end, you must click the closed button on the microcomputer, remember not to directly block the power switch (the same principle as closing the computer).

Instrument operators should carefully read and understand the maintenance of the instrument, maintain the instrument well, so that the instruments are always clean, the parts and accessories are complete and safe, and ensure the normal operation of the instruments. The above is a related introduction to the maintenance method of the tensile tester that is not used for a long time and the details that need to be paid attention to during work. I hope it can help everyone.