News

Maintenance and operating procedures of hydraulic universal testing machine

Release time:2019-10-14 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

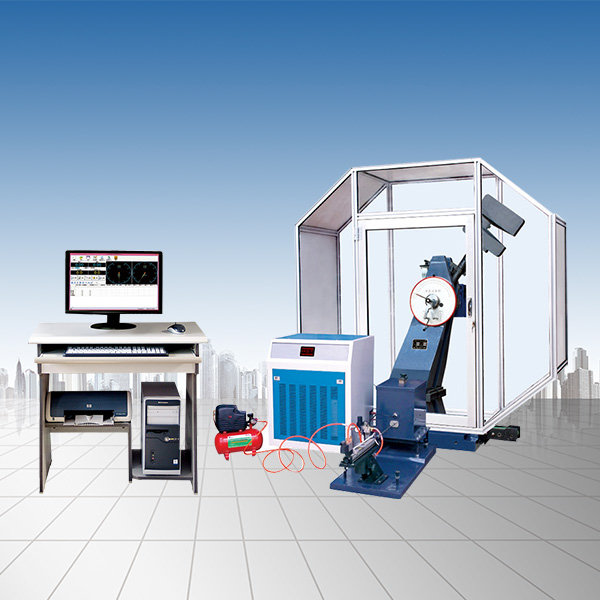

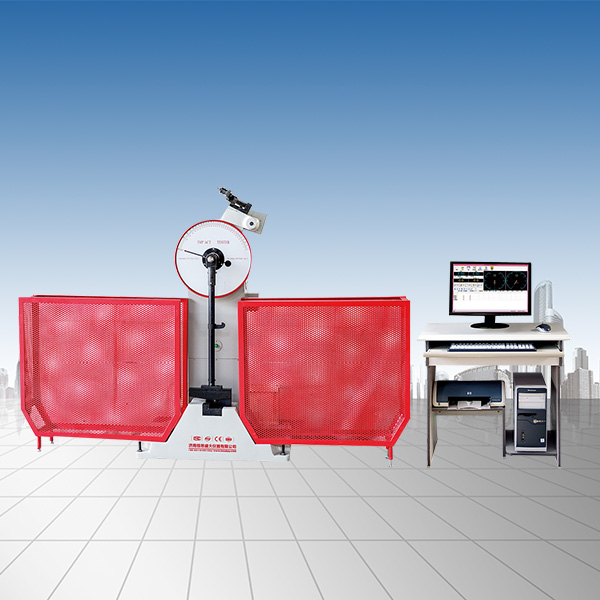

The hydraulic universal test function can carry out various tests such as compression, bending, and tensile testing. The experimental instruments used to tensile, compress, bending and shear various metal and non-metal materials are often found in mining industry and school laboratories and are commonly used test instruments. Let me introduce the maintenance and operating procedures of hydraulic universal testing machines.

1. Maintenance of hydraulic universal testing machine

1. During the test, when the oil pump suddenly stops working, the oil pump should be turned on immediately to remove the sample. It is prohibited to start the oil pump on the high-voltage line or check the cause.

2. During the test, the electrical appliance suddenly fails and the start or stop buttons do not work. The power supply should be cut off immediately to stop the machine.

3. The function of moving crossbeam is to adjust the test space. During the experiment, it is strictly forbidden to start the moving measurement when applying force and unloading force, otherwise it may cause the lifting and lowering driving mechanism to fail.

4. When installing a bent support by hydraulic universal testing machine, pay attention to calculating the distance between the support. The engraving line on the support is the position of the center line of the roller. Incorrect calculations may cause the connecting rod connecting the two support to be broken.

5. For models equipped with hydraulic chucks, the power supply of the oil pump motor should be cut off first when changing the jaws to avoid damage caused by error operation.

6. All parts of the hydraulic universal testing machine should be wiped clean frequently. Wipe the surface without spray paint and apply a quantity of cotton yarn sand to prevent rust. Pay more attention to wiping during the rainy season. When the instrument is not suitable, use a dust cover to prevent dust from invading.

2. Operating procedures of hydraulic universal testing machine

1. Connect the power cord and press the "Power" button. The indicator light is on.

2. Select the range according to the sample specifications, hang or remove the weight on the swing rod, and adjust the buffer handwheel if necessary.

3. According to the shape and size of the sample, install the corresponding jaw into the upper and lower jaw seats.

4. The hydraulic universal testing machine rolls the recording paper (grammed paper) on the drum of the depictor.

5. Turn on the oil pump and unscrew the oil feed valve to raise the table plate by about 10mm, and then close the oil feed valve. If the platen is already in the raised position, there is no need to start the oil pumping first, just close the oil supply valve.

6. Clip one end of the sample into the upper jaw. For models equipped with hydraulic chucks, press the "Tight Up" button on the control box to clamp the sample.

7. When the platen of the hydraulic universal testing machine has risen and the oil return valves are closed, the adjustment point is aimed at the zero point of the accuracy dial. (It should be operated without pressurization)

8. Start the lift motor to adjust the tensile test space and clamp the sample vertically. For models equipped with hydraulic chucks, press the "Tight Down" button on the control box to clamp the sample vertically.

9. Put down the pen of the push rod and enter the drawing state.

10. The hydraulic universal testing machine must have an uplifting speed according to the test requirements, and slowly unscrew the oil supply valve for uplifting test. Close the oil supply valve after the sample is broken. The following test interval is long, and the oil pump should also be stopped.

11. Lift up the depiction pen that records the value.

12. After opening the oil return valve to unload the force, turn the driven needle back to zero point.

13. Remove the broken sample. For models equipped with hydraulic chucks, first press the "Relax" button to loosen the upper jaw, then press the "Relax" button to loosen the lower jaw, and remove the broken samples respectively.

To sum up, this is a detailed introduction to the maintenance and operating procedures of hydraulic universal testing machines. I believe everyone has a certain understanding of this after reading it. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer them one by one. Welcome to call and support!