News

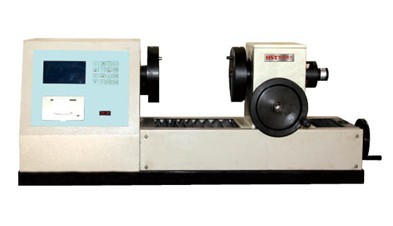

Electronic universal testing machine - Test method for tensile shear strength of rubber and metal bonding

Release time:2023-07-17 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1. Test equipment

1 The selection of electronic universal testing machines should comply with the relevant standards of rubber and plastic tensile testing machines.

2 The electronic tension testing machine should be equipped with an automatic centering device after the sample is subjected to stress so that the loading force direction is consistent with the center line of the sample.

3 The gauge accuracy for measuring the length and width of the bonding surface of the sample shall not be less than 0.05mm.

4 The fixture for preparing the sample should be able to ensure that the glued sample meets the requirements of Chapter 5.

2. Sample

1 The sample should conform to the shape and dimensions of Figure 1. The bonding length of the sample is 12.5mm 0.5mm. The length of the metal sheet is 100.0 nm 0.2 mm, the width is 25.0 nm 0.2 mm, and the thickness is 2.0 nm 0.lmm. The length of the rubber sheet is 12.5mm, the width is 25.0mm, and the thickness is 2.0mm, and the thickness is 2.0mm. The fluctuation of the rubber thickness in the same sample shall not exceed 0.1mm.

2 It is recommended to use LY 12-CZ alloy aluminum, 1Cr18Ni9Ti stainless steel, 45 carbon steel, T2 copper and other metal materials, or other metal materials can be used as needed.

3 The number of conventional test samples should not be less than 5, and the number of arbitration test samples should not be less than 10.

3. Test steps

1 Use a measuring tool to measure the length and width of the sample bonding surface, and it is accurate to 0.05mm.

2 Clip the sample into the upper and lower clamps of the electronic tension tester, and start the universal material testing machine to load the sample at a speed of (50% 5) mm/min until the bond between the rubber and the metal is completely destroyed. Record the maximum load for sample damage and the type of damage of bonding surfaces.

- Previous article:Chain tensile testing machine

- Next article:Characteristics and types of electro-hydraulic servo systems

Recommended productsPRODUCTS