Company News

Introduction to the principle of testing of chuck parts of impact test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

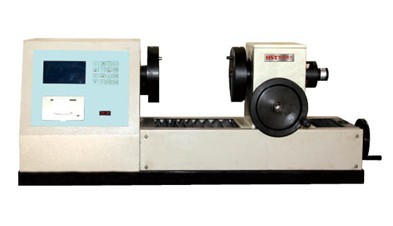

Introduction to the principle of testing of chuck parts of impact test machine

Jinan Hengsi Shanda Instrument Co., Ltd. is semi-automaticImpact testing machine, pendulum impact testing machine, non-metallic testing machine and other impact machines. Our company's technical engineers gave a detailed description of the working principle of the rotary chuck of the impact testing machine:

The low-temperature impact tester equipped with a rotary chuck, the rotation principle of the chuck is as follows: The four chuck blocks are slid at low temperatures with their cylindrical surfaces.Impact testing machineinside the chuck seat. When the chuck seat moves upward along the wedge surface, the four chuck blocks rotate about their axis centers due to the action of the force coupling moment in the horizontal plane, until the plane blade teeth are tangent to the cylinder of the circular sample, that is, the rotation stops when the force passes through the axis, thereby realizing V-shaped clamping. The V-shaped angle increases with the increase of the diameter of the sample. After the round sample is removed, the flat sample begins to be clamped. When clamped, it rotates due to the action of the coupling moment until the plane blade teeth come into contact with the sample plane, the rotation stops automatically, achieving a low temperature.Impact testing machineClamping of flat specimens.

Tags: Testing machine, universal testing machine, hydraulic universal testing machine, tensile testing machine, impact testing machine, material torsion testing machine

Recommended productsPRODUCTS