Company News

The control system of the test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

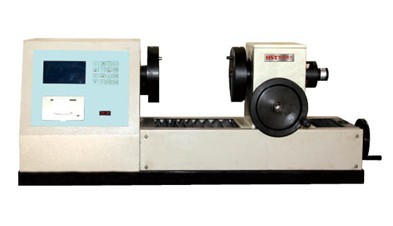

In recent years, at home and abroadTesting machineManufacturers have launched dual-operating systems for testing machines, one operation is a PC control system running on Windows, and the other is a customized small panel control system. It made people's eyes lit up, but it was very popular. The small panel control system did not achieve the expected usage effect, and users were still happy to accept the traditional PC control system.

This phenomenon is not a technical problem. In fact, there are still many remarkable technical aspects of the small panel control systems of various manufacturers. These control systems include three closed-loop controls, which can display test curves in real time, and can also be used for functional designs such as touch screen, USB, and Bluetooth interfaces.

Why are small panel control systems not widely used? To answer such questions, we should first clarify the function of the test machine. In the final analysis, the function of the test machine determines its application. The test machine is actually a mechanical device that obtains the mechanical properties of materials. In the early stages of the development of the test machine, the mechanical properties of the material were reflected on the dial using mechanical devices such as levers. The test curve was recorded through mechanical drums; the application of sensor technology enables the detection quantity to be reflected in digital form, and has developed from analog technology to digital technology. Compared with mechanical material testing machines, the advantage of electronic material testing machines is that they greatly improve the measurement accuracy, and data analysis has become very easy and simple. The role of a computer can be summarized into the collection, transmission, feedback, analysis, display and printing of test data. With the development of electronic technology, the degree of integration of components has been greatly improved, and the PC control system seems too bloated, which is also the driving force for the development of small panel control systems.

The confusion of the two major functions of testing machine control and data processing, or the indistinguishability of the distinction between them, is the main reason why the small panel control system is not widely used.

The advantage of the small panel control system is that it can control the test machine, which can complete the control function with a small body and abandon the connection of the PC. For the device, the test machine itself has a brain and has a more integrated appearance design, and there is no need to be with the PC. With the same control function, is the user willing to conduct the test as soon as the computer is turned on, or does it have to enter Windows after a series of operations and then open the test software before the test is tested. This does not include harassment between viruses and crashes. The answer is obviously the former.

This is of course a wishful analysis from the control itself. On the one hand, users have the mentality that it is not enough without a PC. On the other hand, manufacturers have the idea that there is no control without a PC. Although they have also developed various small panel control systems. From the analysis of failure probability, the more single the function, the more reliable the system. The responsibility of a small panel control system is to enable the device to run efficiently, while Windows focusing on graphics, entertainment and networks seems to be overloaded. Many devices that use computer technology do not choose PCs, but industrial control computers. The main reason is that they are reliable, easy to use and simple.

today,Testing machineThe software has developed unprecedentedly, one is its control function, and the other is its powerful data processing function. After thinking about it, you will find that these may not be the real needs of users. For detection users who care about test efficiency and emphasize reliability, the software is too cumbersome, and simple experimental settings are more reasonable; for research users who care about test details, the software is still not powerful enough. In fact, the data in the software comes from load sensors, beam displacement sensors and extensometers, etc. The software only processes these simple original data to form various experimental data and curves. In order to be compatible, different manufacturers use Access, Word, Excel, Reader, Notepad and other common office software to record experimental data and curves. Even so, some users still use more professional graphics processing software such as Origin for later data processing.

Perhaps such a model can be considered. The test machine uses a small panel control system to control and collect original data to complete the experiments with general requirements. The work of the test machine manufacturer is to provide high-reliability equipment control; users with higher requirements use other software to complete post-processing, and the work of the test machine manufacturer is to provide high-flexible data interfaces.

Of course, in addition to user factors, the selection of control systems also includes many factors such as the development of the control field, market response, production costs, etc. I sincerely hope that the testing machine control system will be more perfect in the future development!

- Previous article:Selection method of environmental testing machine

- Next article:The importance of deformation measurement

Recommended productsPRODUCTS