Company News

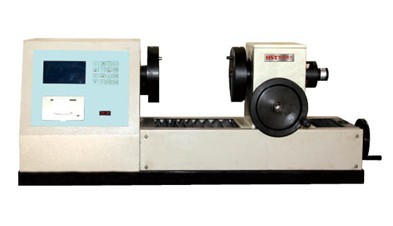

Detailed explanation of tensile testing machine selection

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Use low-priced products to configure parts to use inferior products as good ones. There are many companies in the market today that make machines that are not qualified. And there is no good after-sales guarantee, I hope the manufacturers will consider purchasing! After all, you get what you pay for. Only by buying good quality can you be assured to have good service!

Tension tester products are diverse,

< Tension Testing Machine There are many products. How to choose a tensile testing machine that suits your company has always been a problem for major manufacturers. Let me briefly introduce the methods for purchasing tensile testing machines:

Because the tensile testing machine is also called a universal testing machine, first, you should determine what tests your company's products need to be performed. The tensile, compressive strength, elongation and elongation of various materials, semi-finished products and finished products can be tested, and peeling, tearing, bending, flexure, compression, etc. can be done. The models of various tensile testing machines are different, and the matching fixtures are different, so the prices are of course the same.

For general flexible packaging manufacturers, 2. The tension range needs to be considered. The tension range is about 200N, that is, the one-arm large one is a gantry-type 1 ton. For steel manufacturers, they should consider using such or larger ones...

III. Itinerary,

The stroke of the general tensile testing machine on the market is generally between 600mm-800mm-1000mm, depending on the product you produce. The parts data for testing products should be suitable for most rubber tensile testing machine manufacturers.

4. Measuring speed

There are 0.001 500mm/min or even higher precision, and the speed specified by the national specification is between 10 500mm/min. Wuji speed change has lower accuracy and is cheaper; the latter uses a servo motor and a computer servo system with higher accuracy and higher resolution; purchase according to the needs of each manufacturer.

5. Accuracy

Speed accuracy, including force measurement accuracy. Deformation accuracy, displacement accuracy. These accuracy values can reach plus or minus 0.5. For ordinary manufacturers, 1% amplitude is enough. In addition, the force value resolution can basically reach one hundred thousand...

Generally, those that meet the above specifications are suitable for your company

- Previous article:Electronic tensile testing machine selection

- Next article:Test operating procedures

Recommended productsPRODUCTS