Company News

How to choose an electronic tensile tester for plastics

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

How to choose an electronic tensile tester for plastics

Electronic tension testing machines can extend, bend, compress or pierce the plastic splines at controlled speeds until they break. They are instruments commonly found in plastic compounding manufacturers' laboratories. These manufacturers use electronic tensioners during the mixing process to determine the suitability of the material to a certain process and end-use.

Electronic tensile testing machines are also increasingly common in the laboratories of plastic injection molding and extrusion operators. One reason is that they are increasingly used in cutting-edge product and process development. Another reason is that they conduct more stringent monitoring of the quality control of feed and finished products. Many OEM manufacturers, especially those in medical devices or fields, require plastic processors to conduct their own tests at the end of production operations. Another reason for internal testing is to improve process control, which reduces scrap rates and achieves real returns.

Various tests

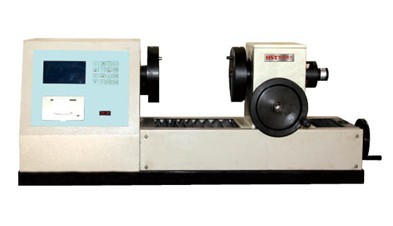

The electronic tension testing machine consists of one (single arm) or two (gate-type) vertical load columns installed on a fixed horizontal substrate with a movable horizontal beam on top. In most electronic tensioners today, the struts are usually driven by lead screws to determine the position of the movable beam.

The specifications of the electronic tension testing machine are expressed by the combination of the load that the frame can bear and the load of the load bearing unit. The load unit is mounted on a moving cross beam driven by motor or hydraulic pressure. The load bearing unit connected to the fixture measures the force and can be read from a digital display or on a computer. Many electronic tension testing machines have interchangeable sensors that can match the material to be tested.

In order to induce strain of the plastic, the electronic tensioner exerts a force on the sample. Special tests for tensile, bending, compression or shear are classified according to the direction of strain induced in the sample and the speed of force applied. Basic testing is completed by a standard electromechanical electronic tension testing machine. They are usually loaded in the speed range of 0.1mm/min to 500mm/min, and different materials require different test speeds. Dynamic and cyclic tests such as rupture growth and fatigue are generally completed over a long period of time and need to be completed on a servo hydraulic electronic tensioner with low loads.

- Previous article:Test machine knowledge

- Next article:How to adjust the universal test machine at different levels

Recommended productsPRODUCTS