Company News

A detailed introduction to the classification and adjustment of universal material testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

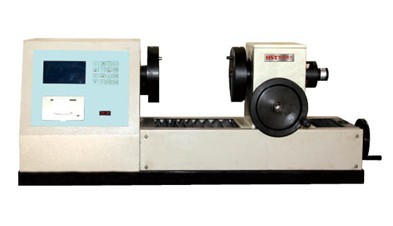

Universal testing machine(UTM) The splines of plastic material are stretched, bent, compressed or pulled through adjustments at different speed levels. This is a common equipment in plastic mixing laboratories. During the preparation of compound mixing, UTM testing materials can be used to determine whether the material is suitable for certain specific processing applications or terminal applications. UTM can also be used for product quality control to ensure consistency between batches of product quality.

UTMTesting machineIncludes one or more vertically loaded columns, a fixed horizontal base is installed on the columns, and a movable horizontal cross head (cross beam) on the top. In today's UTM testing machines, ball screws are usually on the columns to fix the movable cross head. The size of the UTM is characterized by a frame bearing level and a dynamometer measuring load/tension force. The dynamometer is attached to a movable cross head driven by an electric motor or hydraulic device. The series of dynamometers with fixtures measure the magnitude of force, and the results can be displayed through a digital display or PC. Many UTMs have interchangeable dynamometers and therefore can match the different materials tested. Static tests are carried out using standard electronic universal testing machines, and the usual loading speed range is 0.001~20 in./min (1in.=2.54cm). Dynamic or cyclic tests such as crack growth and fatigue tests are usually performed using a hydraulic servo system UTM test machine, which is longer and has a lower load.

Unlike the electronic UTM test machine used for static testing, the hydraulic servo UTM test machine can undergo dynamic testing and fatigue testing. This requires repeated stress application to be performed for a load-release cycle. For example, fatigue crack growth tests, users expect to know how many cycles the material to be tested will break. The stress required for dynamic testing of universal testing machines is smaller than that required for static testing of electronic universal testing machines. The frame capacity of the hydraulic servo system test machine ranges from 100 lb to several tons, and the price is usually 2 to 3 times that of the electronic mechanical test machine. Universal testing machines are basically used for fatigue testing of metal materials, but are increasingly widely used in automotive plastics, aerospace plastics, biomedical plastics, and plastics for electronic components, because structural components with good fatigue resistance are needed in these fields.

MoreMaterial testing machineAll in Jinan Hengsi Shanda Instrument Co., Ltd.

Recommended productsPRODUCTS