Industry Information

How does the impact tester work

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

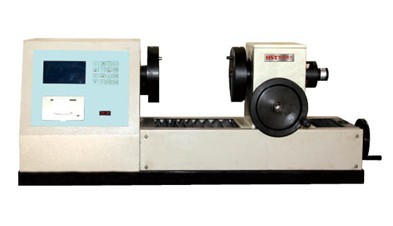

Impact testing machineIt is divided into manual pendulum impact testing machine, semi-automatic impact testing machine, non-metal impact testing machine, etc. It is a new impact testing machine that can instantly measure and record the characteristic curves of materials during impact. By replacing the pendulum and the sample base, two types of tests can be achieved: simple support beam and cantilever beam can be achieved. It detects angular displacement signals and sends them to the computer for data processing, with high accuracy.

At the moment when the impacted sample is impacted by the hammer, it generates a signal through a high-speed load measurement sensor. After being amplified by a high-speed amplifier, it is quickly converted into a digital signal from A/D and sent to the computer for data processing. At the same time, it is sent to the computer for data processing by detecting the angular displacement signal, which has high accuracy. This instrument is equipped with a high-speed angular displacement monitoring system, a force detection sensor and an amplifier based on the impact structure that complies with national standards. Through high-speed sampling and data processing, N-T and J-T curves can be displayed, data storage, data report printing, etc.

The battery is fastened to the test equipment with rigid mounting parts that can support all mounting surfaces of the battery, each battery should withstand a total of three equal-order impacts. The impact should be applied in each of the three mutually perpendicular directions unless the battery has only two axes of symmetry, in which case the test is only performed in both directions. Each impact must be applied in the normal direction of the battery surface. Each impact of the battery must obtain such acceleration, that is, at the initial 3ms, the small average acceleration is 75g (g is the local gravity acceleration). The peak acceleration should be between 125g and 175g. The battery should be tested at 20±5°C (68±9°F).

- Previous article:What issues should be paid attention to when purchasing a test machine

- Next article:How to choose a universal test machine

Recommended productsPRODUCTS