News

Maintenance measures for the control system of torque tester

Release time:2019-03-25 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

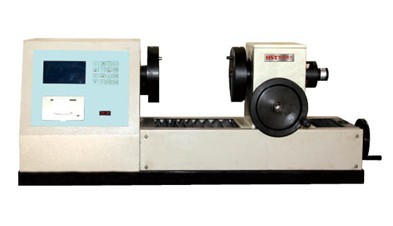

The torque tester is an intelligent multifunctional metering instrument designed and manufactured to test and detect various high-speed impact torques. It is mainly used to detect and correct the torque of various electric air-moving screwdrivers, torque drivers, and torque wrenches. Various products involve tightening force testing, component torsional destructive tests, etc.

The control system of the torque tester is the central control center of the torque tester, and it can also be said to be the "brain" of the torque tester. During the use of the torque tester, we must pay attention to the maintenance of the control system of the torque tester. Once the control system of the torque tester fails, the entire torque tester cannot even start normally. The maintenance measures of the torque tester control system are as follows:

1. Regularly check whether the connection wire on the rear panel of the controller is in good contact. If it is loose, it should be tightened in time;

2. If the machine is not used for a long time after the test, turn off the controller and computer;

3. The interfaces on the controller are one-to-one. If the interface is inserted incorrectly, it may cause damage to the device;

4. The interface on the plug-in and unplug the controller must turn off the power supply of the controller.

In addition, the torque tester control system should regularly replace the oil suction filter and filter element according to the use of the machine and the oil service life, replace the hydraulic oil, and regularly check whether there is any oil leakage at the main engine and the oil source. If there is oil leakage, the seal ring or combination gasket should be replaced in time. The above is a related introduction to the maintenance measures of the torque tester control system, and I hope it can help you.

Recommended productsPRODUCTS