News

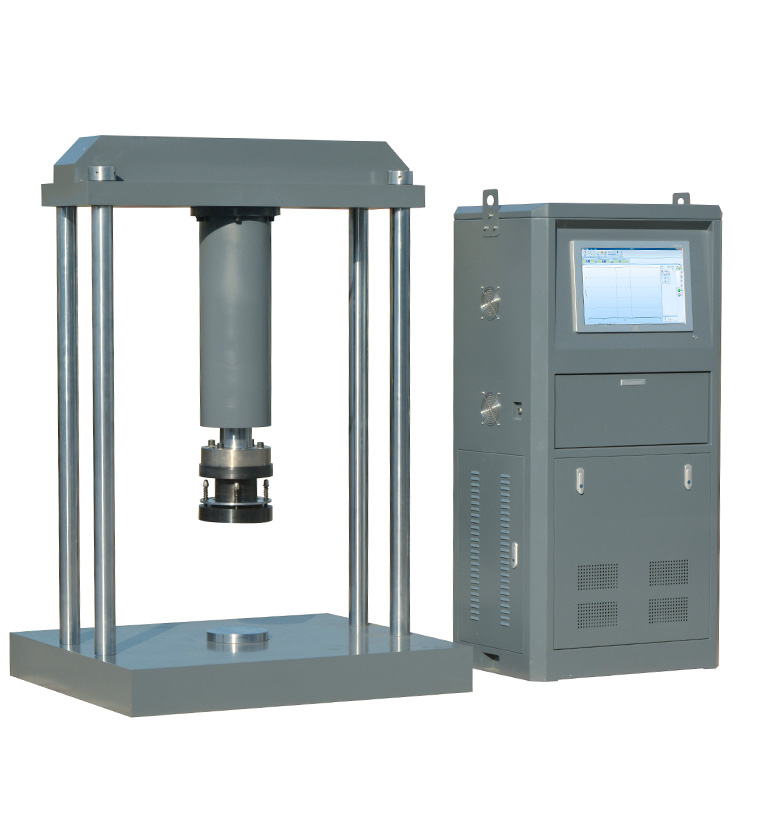

What are the functional characteristics of cast aluminum alloy hydraulic universal testing machine?

Release time:2019-03-26 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Cast aluminum alloy is an aluminum alloy that fills the casting mold with molten metal to obtain blanks of parts in various shapes. It has the advantages of low density, high specific strength, good corrosion resistance and casting process, and small limitations due to the design of parts structure. Cast aluminum alloy products are often used in the automotive industry and industrial production equipment fields in life. Therefore, the mechanical properties of this material are highly required, and machines that conduct mechanical testing of these materials have been widely paid attention to. Cast aluminum alloy hydraulic universal testing machine is a commonly used model.

Most require heat treatment to achieve the purpose of strengthening alloys, eliminating internal stresses of castings, stabilizing structure and part size. It is used to manufacture beams, fuel turbine blades, pump bodies, hangers, wheel hubs, air intake lips and engine receivers, etc. It is also used to manufacture parts such as cylinder heads, gearboxes and pistons of automobiles, instrument housings and supercharger pump bodies. The hydraulic universal test machine of cast aluminum alloy can conduct mechanical properties testing of cast aluminum alloy raw materials and related product components.

So what are the functional characteristics of the cast aluminum alloy hydraulic universal test machine? Let’s make a simple analysis for you:

1. The door structure is novel, beautiful and generous, and the operation is stable

2. The control circuit is highly integrated, with simple structure and reliable performance.

3. The independent dual-channel fully digital program-controlled amplifier realizes the true sense of physical zeroing, gain adjustment and automatic shifting, zeroing and calibration of test force measurement.

4. Automatic storage of test conditions, test results, calculation parameters, and gauge distance positions.

5. After the test is completed, the beam of the test machine will automatically return to the initial position of the test.

6. Different reporting forms can be output according to user requirements.

7. It has protections such as overcurrent, overvoltage, undercurrent, and undervoltage; the stroke has triple protection for program-controlled limit, limit limit, and software limit. Emergency braking can be performed when an emergency occurs.

The market for cast aluminum alloy hydraulic universal testing machines is close to saturation. Due to the competition between domestically produced machines and imported machines, many people have always been interested in the performance stability of imported machines and ignore the overall improvement of the functional characteristics of local products. The machines of many existing domestic manufacturers can meet internationally recognized quality testing standards. The above is the relevant introduction to what are the functional characteristics of cast aluminum alloy hydraulic universal testing machines? Hope it can help everyone!

Recommended productsPRODUCTS