News

Operating procedures and common fault maintenance methods of LCD pendulum impact tester

Release time:2019-06-24 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

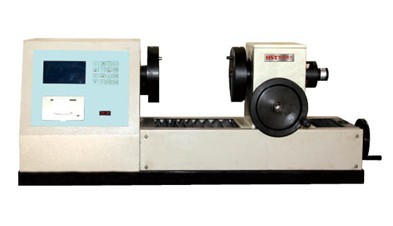

The LCD pendulum impact testing machine is a common mechanical testing equipment to ensure the accuracy and good operation of the impact testing machine. You may not be unfamiliar with the LCD pendulum impact tester, but many people may not be clear about its operating procedures and common fault maintenance. Below, our technicians will share with you the operating procedures and common fault maintenance methods of the LCD pendulum impact tester.

1. Specifications for the use of LCD pendulum impact test machine

(1) Sample preparation: Select the specified sample size according to the product standards, and the surface in the width direction of the sample is the product compressed surface.

(2) The width and thickness of the sample should be measured in three points in the middle of the sample and the arithmetic average value should be taken. The thickness of the sample should be measured on both sides of the notch and take its arithmetic average.

2. Operation steps of LCD pendulum impact tester:

(1) Turn on the power supply of the test machine and start the swing to ensure that the pendulum has been placed in the pre-lift hook position. (referring to 150° on the right)

(2) Place the sample and place the sample horizontally on the bracket to cause impact load on the back of the sample notch.

(3) Select the range according to the hammer head and turn the knob to the corresponding range position.

(4) Pull the cancel and impact buttons to allow the pendulum to fall freely, causing the sample to be subjected to impact load.

(5) Read the numerical values and record the test data to prepare for the next impact.

3. Common fault maintenance of LCD pendulum impact tester

1. The pendulum should be removed during the moving process to avoid shaking and destroying the relevant parts.

2. Do not put the pendulum that is not used together and nearby, so as to avoid deformation caused by bending of the pendulum.

3. The parts of the pendulum must not be disassembled or replaced at will to avoid changes in the pendulum torque and the central position of the blow.

4. If you find that the operating mechanism is not working, the pendulum cannot be hung or the pin cannot be disassembled, the relevant parts can be removed and washed with kerosene, and applied a little lubricating oil, and reinstalled in place.

5. If there are no abnormal reasons for the LCD pendulum impact test machine, the pointer after the empty hit should point to the zero point of the dial, and the computer displays it as 0.01J. If the pointer after the empty hit is deviated from the zero position and exceeds 0.1% of the maximum impact energy of the corresponding pendulum, and the calculation display is not 0, you can check the following points, whether the test machine is looking for a good level, whether the position of the active needle is adjusted correctly and tightened, whether the swing rod is bending and deformed, and whether the friction of the test machine increases, the nut and flange cover should be reliably tightened to avoid axial movement of the ball bearing and the swing shaft. Whether the working surfaces of the hanging latch and hanging hook are showing signs of wear. The distance between the magnetic clutch and the armature of the tooth embedded electromagnetic clutch is inappropriate. If the three steel balls contact the magnetic clutch end face of the embedded electromagnetic clutch in the event of power outage, the friction will increase. The distance between these two is 1.2-2mm, and it has been adjusted when leaving the factory.

6. The failure of the lifting and swing may be that the motor belt is too loose and the electromagnetic clutch is faulty. At this time, it is necessary to adjust the elasticity of the belt, repair the electromagnetic clutch, and troubleshoot the fault.

The above is the operating procedures and common fault maintenance methods of the LCD pendulum impact tester introduced to you. I hope the above brief introduction can help you. If you want to know more detailed information about the tester, you are welcome to follow our company. This not only provides you with high-quality tester equipment, but also provides various equipment information to help you further understand the equipment. If you have any needs, please come and consult.

Recommended productsPRODUCTS