News

Functional characteristics, maintenance, working conditions and precautions of the tightening wheel fatigue test machine

Release time:2019-06-22 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

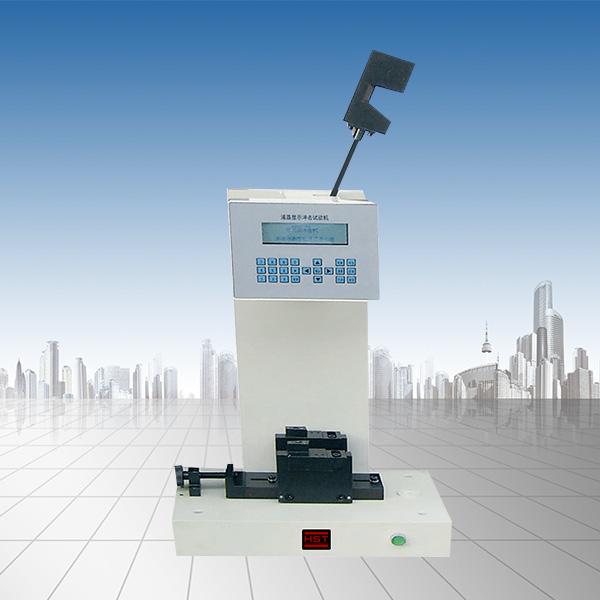

The tightening wheel fatigue test machine is mainly used for fatigue life tests of various coil springs, disc springs, shock absorbers, sealing springs, etc. Widely used in spring, shock absorber production, application and other industries. Before choosing to buy any machine, you must fully understand its functional characteristics and other aspects. So what are the functional characteristics, maintenance, working conditions and precautions of the tightening wheel fatigue tester? Let’s take a look.

1. Functional features of the tightening wheel fatigue test machine:

(1) AC servo driver and AC servo motor have stable and reliable performance, and have protection devices such as overcurrent, overvoltage, overspeed, overload, and limit.

(2) The control method is divided into two types: microcomputer control and manual box control. Manual box control can be operated offline, reducing labor intensity and improving test efficiency.

(3) The test can select various curves such as stress-strain, force-elongation, force-time, strength-time, etc., and curve comparison and image analysis can be performed.

(4) The equipment can be equipped with sensors, extensometers, large deformations, high and low temperature boxes and fixtures of different specifications to broaden the measurement range and achieve multi-purpose one machine.

(5) It can automatically store data, automatically identify, and control multiple times, retrieve previous test data and curve comparison analysis, and print test reports.

2. Pay attention to maintenance and maintenance, which can increase and extend the service life. Let’s take a look at how to maintain and maintain the use of the tightening wheel fatigue test machine, thereby saving costs for the enterprise and avoiding unnecessary expenses:

1. Be protected from heavy blows during use and handling to avoid affecting the measurement accuracy of the equipment;

2. During the test, check whether the indicator light is correct;

3. The nuts of the equipment must be tightened regularly to avoid loosening;

4. The tightening wheel fatigue test machine should be placed in the best environment and should not be too humid to keep the air circulating;

5. Do not move the components of the equipment at will. Some electronic parts and circuit boards are very sensitive to static electricity. It is inevitable that there will be some static electricity on people, which may be damaged due to this;

6. Operators should read the instructions carefully to avoid damage to the equipment caused by improper operation. Non-professionals should not operate the equipment easily. Once abnormal situations occur in the machine, they should stop the operation in time and obtain it with technical personnel.

3. Working conditions of the tightening wheel twist test machine:

1. Within the range of room temperature of 10°C to 35°C, the relative humidity is ≤80%;

2. On a solid foundation or workbench;

3. In an environment without vibration and surrounding corrosion;

4. The fluctuation range of the power supply voltage should not exceed ±10% of the rated voltage.

4. The tightening wheel torsion fatigue testing machine is a relatively practical product. Because it is used frequently, some problems will arise during daily use. So what issues should be paid attention to during use? The following is a brief introduction:

1. Be protected from heavy blows during use and handling to avoid affecting the measurement accuracy of the equipment;

2. During the test, check whether the indicator light is correct; and the nuts of the equipment must be tightened regularly to avoid loosening; pay special attention to the placement environment of the torsional fatigue test machine, it is best not to be too humid to keep the air circulating;

3. Do not move the components of the equipment at will. Some electronic parts and circuit boards are very sensitive to static electricity. It is inevitable that there will be some static electricity on people, which may be damaged due to this;

4. Operators should read the instructions carefully to avoid damage to the equipment caused by improper operation. Non-professionals should not easily operate the equipment. Once the machine is abnormal, stop the operation in time and contact the manufacturer's after-sales technician.

Instrument operators should carefully read and understand the functional characteristics, maintenance, working conditions and precautions of the tightening wheel fatigue test machine, maintain the instruments well, keep the instruments clean, and keep the parts and accessories intact and safe, and ensure the normal operation of the instruments. If you want to know more details about the test machine, you are welcome to follow Hengsi Shanda. This not only provides you with high-quality test machine equipment, but also provides various equipment information to help everyone further understand the equipment. If you have any needs, please come and consult.

Recommended productsPRODUCTS