News

Functions and operation procedures of the measurement and control system and software of the four-ball wear tester

Release time:2019-07-02 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

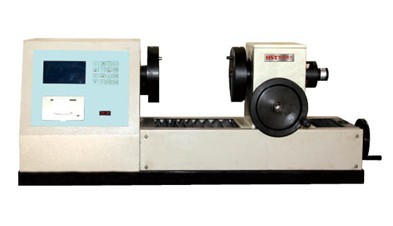

The four-ball wear tester is a simulation evaluation tester necessary for the development of various medium and high-end series hydraulic oils, internal combustion engine oils, and gear oils. It adopts the principles of microcomputer control, LCD dynamic display, and mechatronic integration to conduct set friction tests. Before the test, input the friction times required by the test standard or the operator's custom number of frictions is input to the control system. The test can achieve automatic control and beep after each test is completed. The layer to be ground and the friction paper of the sample rub against each other at a predetermined speed under the action of the load friction body. The wear resistance of the ink layer (or coating) is judged by measuring the reduction of density before and after friction (or coating thickness reduction). The four-ball wear test machine adopts a color touch screen control method, which can set and display the spindle's test parameters in real time such as rotation speed, rotation number, test force, friction torque, friction coefficient, test time, temperature, etc., and can collect test data in real time and draw corresponding test curves.

The four-ball wear tester mainly uses sliding friction to evaluate the bearing capacity of the lubricant under extremely high point contact pressure conditions. The dissolution ability of the four-ball wear tester is usually expressed by aniline dots. The dissolution limit of composite additives of different grades of oils is different. The limit value of low ash oil is larger than that of overly alkaline oil, and the limit value of single-stage oil is larger than that of multi-stage oil. In addition to general physical and chemical properties, greases for special purpose also have their special physical and chemical properties. For example, grease with good waterproof properties requires water spray test; low-temperature grease must be measured for low-temperature torque; multi-effect grease must be measured for extreme pressure wear resistance and rust resistance; long-life grease must be tested for bearing life test, etc. There are also corresponding test methods for determining these properties. What I want to share with you this time is the measurement and control system and software usage functions and operation procedures of the four-ball wear test machine.

1. The functions of the four-ball wear test machine measurement and control system and software use are as follows:

(1) Implement national standards (lubricant extreme pressure performance measurement method), (four-ball method anti-wear test method) and other test methods;

(2) Friction force, peak value and load, the accuracy is ±1% of the starting value of 20% per range, and the four-ball wear tester can be automatically calibrated;

(3) Display the motor rotation number (speed) and test duration in real time;

(4) The four-ball wear test machine has multiple protection functions: friction, load, motor rotation number, etc.;

(5) Record the friction force-time and load-time test curves in real time and sample at high speed;

(6) The four-ball wear test machine uses a variable structure PID control algorithm to adjust the loading process, with the constant speed control error ≤5%, and the pressure holding control error ≤0.5%;

(7) When the test force is greater than a certain upper limit, the four-ball wear tester system will automatically enter the overload protection and take certain measures in a timely manner to ensure the safety of the four-ball wear tester;

(8) The test data of the four-ball wear test machine is managed by data file, which can save all test data and curves, and the format of the printing test report meets the national standard requirements.

2. Operation process of four-ball wear tester:

1. First, on the premise of ensuring the correct wiring, turn on the power supply note 1 and turn on the air switch on the left side of the device. At this time, observe that the red indicator light of the power supply is on, indicating that the power supply has been turned on;

2. Press the power switch of the four-ball friction test machine, turn on the system power supply, and then the green indicator light on the power supply, press the computer on button to start the computer control system;

3. After entering the system, open the special control system for the four-ball friction test machine to check whether each parameter is displayed normally;

4. Check the sample clamping condition, maintain the no-load state, select the friction pair, set a low speed, start the equipment, and pay attention to whether the equipment is operating normally;

5. Use solvent gasoline to clean the oil box, steel balls for testing, fixtures and other parts that come into contact with the sample during the test process. Wash twice with petroleum ether, and dry them. After cleaning, the steel balls should be free of residue and smooth without rust spots. Select the cleaning method and number of cleaning times according to the on-site situation and test requirements, and keep the working conditions of each test consistent;

6. The four-ball friction test machine uses special tools to clamp the sample, fix the steel balls in the upper ball seat and oil box of the four-ball machine, pour the sample into the oil box, and let the sample cover the steel ball to reach the joint of the press ring and the nut. If it is a test grease, first install a sufficient amount of grease in the oil box, insert the grease into the grease, place the press ring, tighten the nut to fix the oil box, smooth the grease on the surface and adjust it to the junction of the press ring and the nut. There should be no holes in the sample;

7. Install the steel ball, and then place the oil box containing the sample and ball in the middle on the torque wheel;

8. The four-ball friction test machine sets the test force value according to the compensation table of PB note 2, the setting time is 10s and the rotation speed is 1450r/min.

Mechanical equipment is essentially the same. Only by mastering the correct method can the entire experimental process be smoother and the experimental data are more accurate. The above is the function and operation process of the measurement and control system and software of the four-ball wear tester. If you have any questions during use, you can call our service hotline through the web page. Our company will arrange technicians to answer it for you. Your call and inquiries are welcome.

Recommended productsPRODUCTS