News

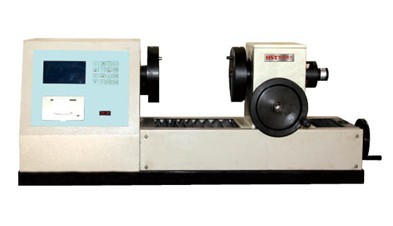

Requirements and testing steps for Richmond hardness meter

Release time:2019-07-10 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The Richter hardness meter is a testing equipment. Its principle is that with the development of monolithic technology, in 1978, Swiss Dr. Leeb first proposed a new hardness measurement method. Its basic principle is that an impact body with a certain mass impacts the surface of the sample under the action of a certain test force, measure the impact speed and return speed 1mm from the surface of the sample, and use the electromagnetic principle to induce a voltage proportional to the speed. So what are the requirements for the use of the Richter hardness meter? Below we will make a detailed analysis of the use requirements and testing steps of the Richter hardness meter:

1. Requirements for use of Reyrian hardness meter:

1. Generally required for the test part, the surface of the test part should be clean, free of dust, oil and scale.

2. The temperature of the test piece surface temperature of the Richter hardness meter requires that the temperature of the test piece surface cannot be overheated, and the temperature is required to be less than 120℃. The optimal test temperature is 4℃-38℃.

3. Requirements for surface roughness of the specimen. The surface roughness of the specimen should meet the requirements of the table below. The roughness of the specimen surface not only affects the test accuracy, but also affects the service life of the impact ball head.

4. Requirements for the weight of the specimen by Richmond hardness meter

(1) The Richter hardness meter does not require support for sufficiently heavy specimens, and conducts direct testing.

(2) For specimens with less weight, specimens with overhangs and thin-walled specimens should be supported by objects during testing to avoid the distortion, deformation and movement of the specimens caused by impact.

(3) For test pieces with smaller weight, they should be firmly coupled to the support body with a large weight and 5kg. The surface of the test piece and support body must be flat and smooth. The amount of coupling agent (Vaseline, engine oil, etc.) should not be too much, and the test direction must be perpendicular to the coupling plane.

5. Requirements for the thickness of the surface hardening layer of the specimen for Richmond hardness meter. For specimens with surface hardening layers, in order to ensure the test accuracy, the thickness of the surface hardening layer of the specimen for different impact device specimen is required.

6. Requirements for the thickness of plate and tube wall specimens of Richmond hardness meter. Testing of plate, tube and other sheet specimens is to ensure the test accuracy.

7. The Richter hardness meter requires that the test accuracy of the curved specimens be used to ensure the test accuracy of the curved specimen using a D-type impact device, which requires the curved surface radius of the specimen to be greater than 30mm; the G-type impact device is used, which requires the curved surface radius of the specimen to be greater than 50mm. For spherical, cylinder and concave curved test pieces that do not meet the above requirements, special-shaped support rings (optional parts) should be used to ensure the test accuracy.

2. Test steps of Richter hardness meter:

(1) The object to be detected should be placed flat on the ground, and it must be absolutely stable, and there must be no shaking. The position to be detected must not be suspended. If necessary, support blocks must be added;

(2) Turn on the Richter hardness meter → the material settings of the object → the hardness value setting (HRCHRBHB) → the hardness detection direction setting → start hardness detection;

(3) Press the impact device on the surface to be measured and press it down. After 1s, press the small cylinder protruding above the hardness meter, and the hardness value will be automatically displayed. During this process, the operator must steadily lower the impact device and the direction should also be kept perpendicular to the surface to be measured;

(4) Each test site should test at least 3 points, and the distance between the two test sites should be ≥3mm. After the test, take the average value as the hardness of the part, record it, and then enter the next part to test;

(5) Compare the test results of the Richter hardness meter with the requirements of the object. If the requirements are met, they will be qualified and transferred to the next process; if they fail, they will be transferred to the isolation area and record the test results;

The above is the requirements and testing steps for the use of the Richter hardness meter that you introduced to you. In fact, it is not difficult to operate the Richter hardness meter correctly, but the staff must be careful. Many of the processes in the middle are relatively trivial, which is indeed very important. Through today's understanding, I hope it can help staff solve problems and improve work efficiency. Friendly reminder: If you have any unclear areas, please call us for consultation.

Recommended productsPRODUCTS