News

Operating procedures, safety protection knowledge and working conditions of the torsion test machine

Release time:2019-07-08 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

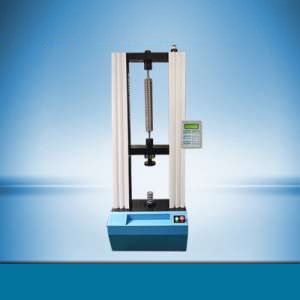

Torsion test machines can be roughly divided into three types. As the market demand for twisting test machines becomes greater and greater, people's understanding of them is gradually deepening. Then, let's share the operating procedures, safety protection common sense and working conditions of twisting test machines. I hope that everyone will pay attention to safety and use them correctly during the process of using twisting test machines.

1. Operating procedures of the torsion test machine:

Before the torsion test machine, check whether the connections of the test machine are normal. Prepare samples and measuring instruments, and select appropriate fixtures and clamps. Start the computer and printer, and turn on the power supply of the test machine host. Open the test machine measurement and control system software and connect it online. If the online connection is successful, the test LCD screen will display the words "PC control".

Correctly set the hardware and software settings of the software and enter the environment parameters. Measure the size of the sample and enter the size information of the sample in the software run parameter window. First hold the sample at one end of the sensor, and then clear the torque value in the software. After the torque is cleared, adjust the fixture position clockwise or counterclockwise to clamp the other end of the sample.

After the torsion tester is tightened by the sample, if there is a torque force value. Press the "Mechanical Zero" button in the test machine panel, and then manually rotate the test machine handwheel to zero the torque force value. Press the "Mechanical Zero" button to clear the angle value. Assemble a small angle device to clear the digital display value. In the software's operation parameters window, correctly set the various operation parameters of the test according to the test requirements.

Click the Run button and the experiment begins. When the small angle reaches the preset value, please remove the small angle in time to avoid damage. The sample is destroyed and after the test is completed. Output the test results to the table and print the test report. Remove the damage sample, clean the test bench, and maintain the test environment sanitation. After the test is over, turn off the power supply, computer and printer of the test host.

2. Common knowledge on safety protection of torsion test machines:

1. The torsion test machine or parts and components with large components should be easy to lift and equipment, and should be equipped with lifting holes or lifting rings, etc.;

2. There are parts and components that can be loosened during operation of the torsion test machine, and should be equipped with anti-loosening installation;

3. The exposed sliding parts, gears, pulleys, etc. of the torsion test machine should be protected and installed;

4. The hydraulic system should be installed safely with pressure regulating;

5. Safe installation and limit installation should be flexible and reliable;

6. When it is required to twist separately, the arrows with moving bias should be marked outside the appropriate parts;

7. There should be high-quality grounding installation on the electrical box of the torsion test machine base. The grounding installation position should be convenient for wiring and have the word "grounding" or grounding mark.

3. Introduction to the working conditions of the torsion test machine:

1. Within the range of room temperature of 10°C to -35°C, the relative humidity is ≤80%;

2. On a solid foundation or workbench;

3. In an environment without vibration and surrounding corrosion;

4. The fluctuation range of the power supply voltage should not exceed ±10% of the rated voltage.

The operating procedures, safety protection knowledge and working conditions of the twisting test machine are introduced. The above is the relevant introduction to this issue. Mechanical equipment is essentially the same. The coordinated operation of different components can only make the entire experimental process smoother and the experimental data more accurate. Hope the above introduction can help you.

Recommended productsPRODUCTS