News

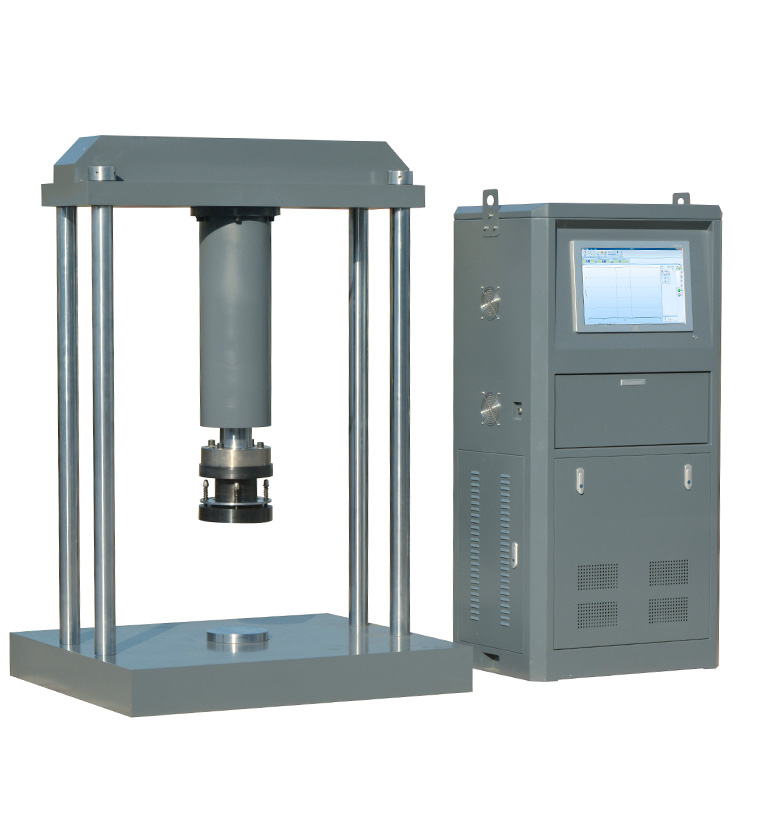

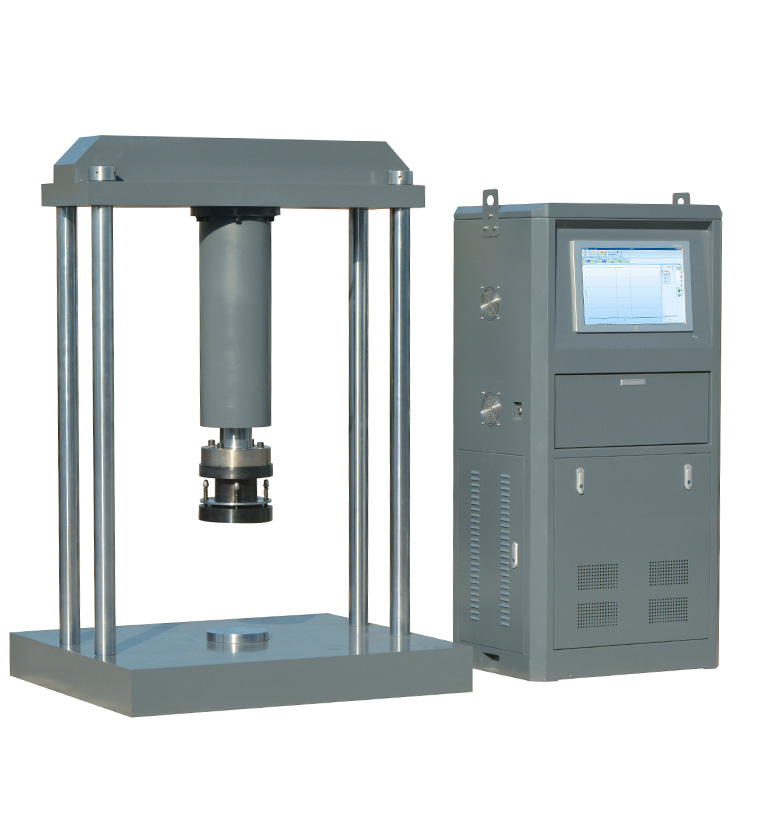

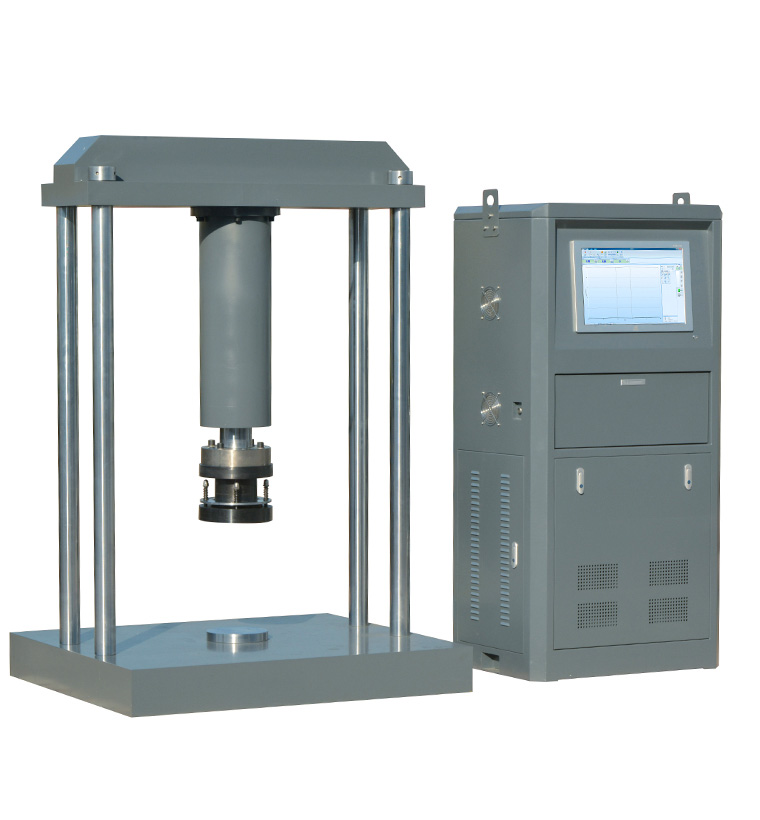

Do you know the operating procedures of the static load anchor tester and how to install and debug?

Release time:2019-07-31 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The load anchor tester is mainly used in the detection of the anchoring coefficient of steel stranded wires in railways, bridges, buildings, power and other infrastructure construction, and can meet the technical requirements of porous static load anchoring performance testing of relevant national regulations. It is a necessary testing equipment for construction projects. So do you know the operating procedures of the static load anchor tester and how to install and debug? Let’s take a look together.

1. Operating procedures of static load anchoring test machine

1. First perform the tensile strength test of the steel strand.

2. Choose the appropriate pad according to the type of anchor and place it in the jack and sensor.

3. Connect the wires of the computer and controller, controller and sensors to turn on the power supply.

4. Place the steel stranded wire into the anchoring system hole of the static load anchor tester, and put the anchors and clips on both ends. Keep the direction of the anchor holes at the tensioning end and the fixed end consistent.

5. Use a small tension jack to adjust the initial stress of each steel strand, and the initial stress can be 5%~10% of the standard tensile strength of the steel strand.

6. Measure the distance between the tension end and the fixed end anchor as the test standard value.

7. According to the standard value of tensile strength of steel strands, the loading reaches 80% in five levels, etc., the retractable amount △a of the steel strands and the relative position △b of the clip should be measured under loads at each level.

8. After the static load anchor tester is loaded for 1 hour under 80% load, it is gradually loaded to damage, and records the measured limit tension and the stroke of the piston when the steel strand is broken.

9. Continue with the next set of tests and repeat steps 4 to 8.

10. After the test is over, turn off the power supply and clean it.

2. Installation and debugging of static anchor tester

The static load anchor test machine should be installed in a room with a clean, dry, no vibration and room temperature between 10℃-35℃. Enough space (≥1m) should be left around the test machine for testing and maintenance. The main body and control cabinet of the test machine should be installed on a concrete foundation. The foundation size is based on the appearance and foundation map, and the base screws and other wire installation pipes are left to adjust the upper plane of the foundation.

Preliminary correction of installation accuracy of static load anchor tester

Preliminary body correction: Use a frame level or borrow a wire hammer in the accessory to correct the perpendicularity of the column in two directions perpendicular to each other, and adjust it by inserting small iron sheets at the bottom of the body. Hang the anchor screws.

Connection of hydraulic system of static anchor tester

a. Remove the bundles in each part and clean the inside of the oil pipe with clean kerosene.

b. Check whether the gasket at the joint is complete. If it is damaged due to transportation reasons, use the new gasket included in this machine to prevent oil leakage during high pressure.

c. Use a suitable wrench to connect each oil pipe.

d. This equipment usually uses N68 anti-wear hydraulic oil. When the ambient temperature is too high, N100 hydraulic oil is added to increase the viscosity according to the situation.

Electrical installation of static anchor tester

The power supply voltage of this equipment is 380V in three phases, and the equipment must be grounded. The electrical connection between the main body and the control cabinet is made of plugs. Before powering on, open the iron door of the control cabinet to check whether it is falling off at all connections, whether the fuse is loose, and remove dust and debris in the electrical box. After confirming that the equipment is connected to the power supply line, press the "Power" on the control counter panel to match the text shown on the button. If the opposite is true, change any two phase lines; unscrew the oil feed valve and raise the piston, open the shutoff valve, and refer to the ruler on the main column to check whether the piston stroke limit switch is in effect; then close the oil feed valve after slightly raising the working piston.

Debugging of static anchoring test machine

Turn off the oil pump motor, rotate the M8 wire on the oil pump to block the air in the pump (with a small amount of oil) and then rotate the wire to block the air; start the oil pump and repeatedly raise the piston, and drain the air in the oil cylinder and oil pipes to observe that the return oil is continuous and stable.

If the force value is found to be stagnant in a certain area during the pressure test, perform the following operations:

a. Select the maximum range, adjust the working pressure to half of the range and stabilize.

b. Open the iron door of the control cabinet, rotate the exhaust wire on the right side of the outer circle of the oil supply valve, and then rotate it back.

c. When performing the above operations, you must pay attention to: ① The working pressure should not be too high; ② The force should be light and slow when the exhaust wire is blocked and rotated, and be careful not to break it.

When using the press tester, the operator must use it in accordance with the procedures and specifications of the instructions. Otherwise, it will easily cause machine failure and personnel injury. The above is the installation, debugging and operating procedures of the static load anchor tester, which I hope can help everyone.

Data-driven global marketing- Previous article:Structure and use of metallographic microscope

- Next article:Maintenance and precautions for hot and cold impact testing machines

Recommended productsPRODUCTS