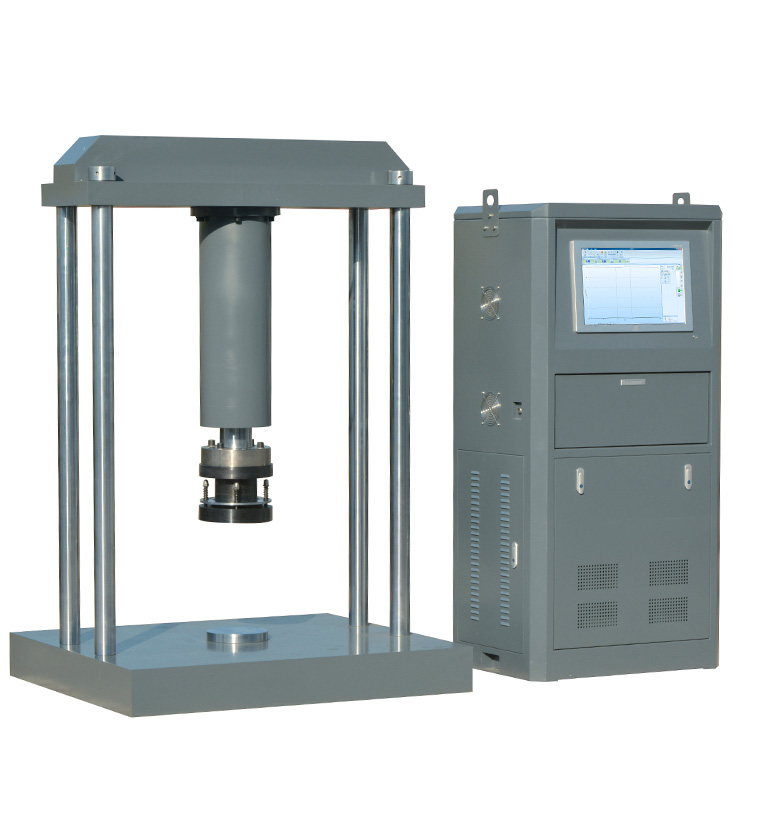

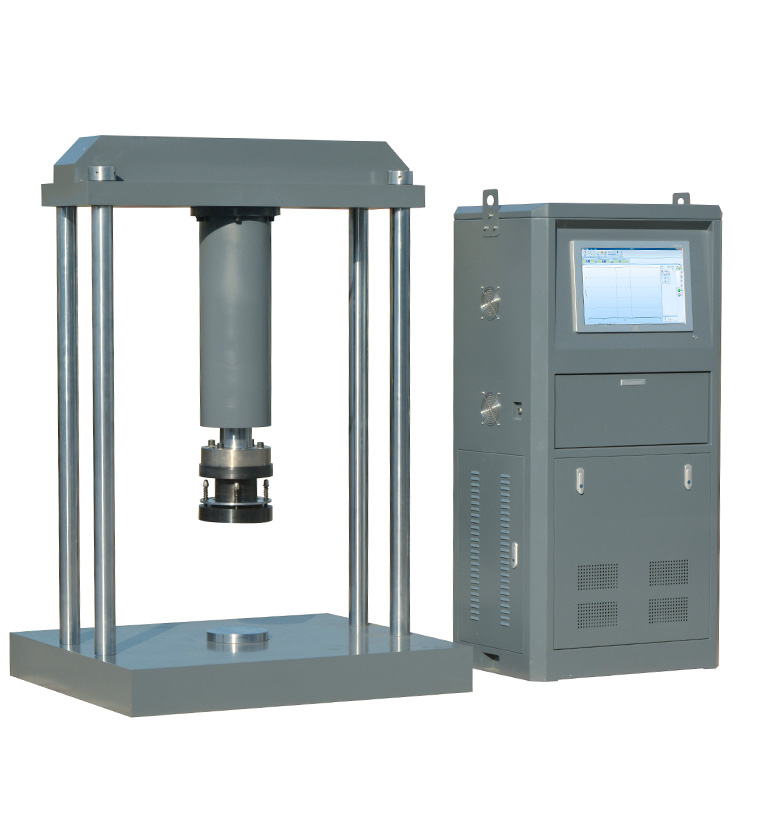

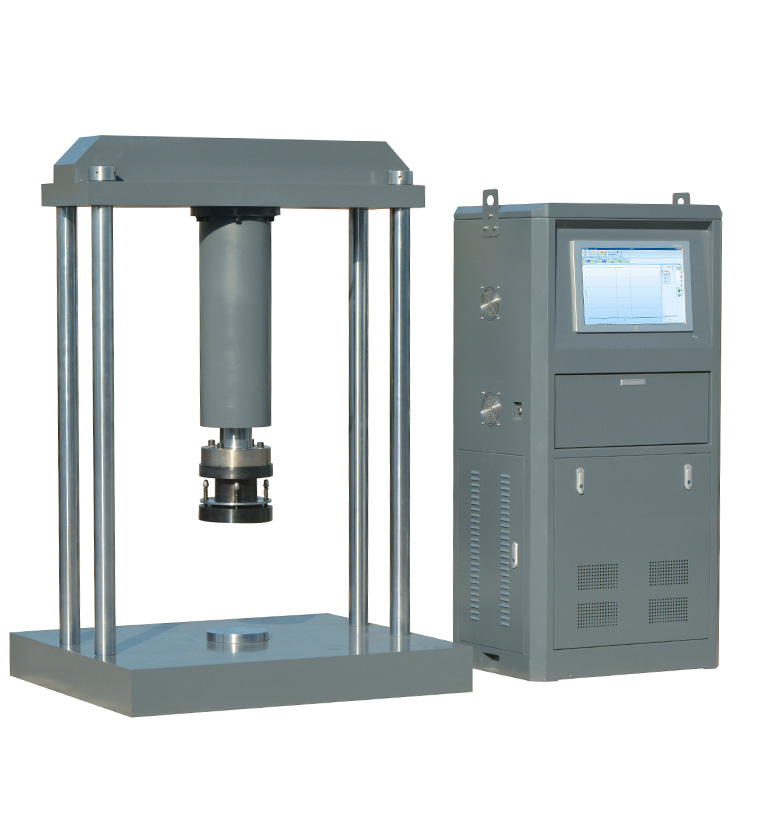

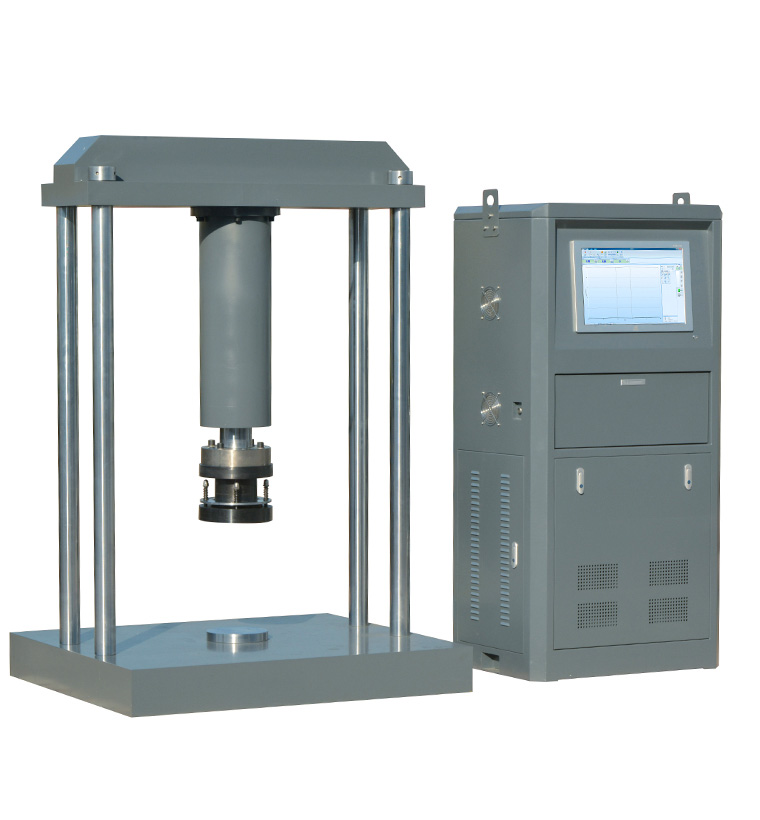

The tensile tester of pipe welding joints can conduct testing of metal materials and non-metallic and polymer materials for tensile, peeling, compression, bending, shearing, top breaking, puncture, fatigue and other items. It can be compiled according to the requirements of customers' products according to GB, ISO, ASTM, JIS, EN and other standards, and can automatically obtain the maximum test force, breaking force, yield force, tensile strength, compressive strength, bending strength, elastic modulus, elongation, constant elongation stress, fixed stress elongation and other parameters.

![Performance characteristics of tensile tester for pipe welding joints [Information]](http://www.hssdtest.com/uploads/image/20250418/57/cc50208c2c64d084a09ade0195536f4d.jpg)

Performance characteristics of the tensile tester of pipe welding joints:

1. The control test process of AC servo motor and AC servo speed regulation system is adopted, and the control accuracy and quality are greatly improved, stable and low noise (basically no noise at low speeds) and the control speed range is greatly widened (0.05-300mm/min);

It is conducive to low-speed tests of conventional materials (metals, cement, concrete, etc.), and high-speed tests of non-metallic materials (rubber, etc.). It can also be used to quickly adjust the test space when no load, saving auxiliary test time.

The test speed of the tensile tester of pipe welding joints meets the current requirements for the test speed of all conventional metal and non-metallic materials in China.

2. The reduction mechanism composed of synchronous tooth belt and precision ball screw pair "strong" joints make the structure simpler and brighter, and the transmission efficiency is greatly improved. The lower table height and the height of the main machine's lower workbench also decrease, making the appearance more coordinated.

3. Adopt a dual-space structure independent of stretching and compression, which is convenient to operate, avoiding the cumbersomeness of replacing different test attachments when stretching and compression bend in the same space.

4. Sensors of different specifications can be configured according to the requirements, so that the test range is greatly widened to meet the measurement requirements of different test loads.

5. The main machine adopts a fully sprayed shell, which has a generous and beautiful shape.

6. The tensile force test machine of pipe welding joint adopts advanced control technology, with three closed-loop control methods: stress, strain, and displacement. Each control ring can automatically switch, and achieve impact-free smooth transition when switching between various methods. It can simultaneously display the test force, peak, displacement, speed, test status, test curve, etc.

7. The test force, deformation, displacement and other rate control and maintenance can be carried out.

8. It can realize fast/slow lifting and lowering adjustment of the crossbeam during sample clamping, and can be flexible in operation and random switching.

9. It has the function of returning to the initial position after the test is completed, which is fast.

10. It has complete limit protection functions and functions such as overload, overcurrent protection, automatic shutdown of test fracture, and other functions, which are reliable and safe.

11. Build a powerful test database for self-built, and test data can be saved, queried and called at any time.

12. The tensile test machine of the pipe welding joint provides a variety of report printing interfaces. Users can edit reports in any format as needed and print output;

13. The entire control system has high cost performance and high reliability.

14. Perform tensile tests on the material according to national standards or standards provided by users, and count and process the test data, and then print various required test curves and test reports;

You can select real-time display, amplification, comparison, traversal functions and monitoring of the test process such as load-time, load-displacement, displacement-time, deformation-time, etc. Intelligent and convenient.

The performance characteristics of the tensile tester of pipe welding joints are introduced here. For more information about the tester, please consult our company. Our company has complete testing instruments to ensure that accurate and high-quality testing equipment is provided. Welcome new and old customers to visit and negotiate! Our company has been focusing on the production of test machines for twelve years and is a professional manufacturer of mid-to-high-end test machines!

Who can become a "consumer asset" monetary?

![Performance characteristics of tensile tester for pipe welding joints [Information]](http://www.hssdtest.com/uploads/image/20250418/57/cc50208c2c64d084a09ade0195536f4d.jpg)