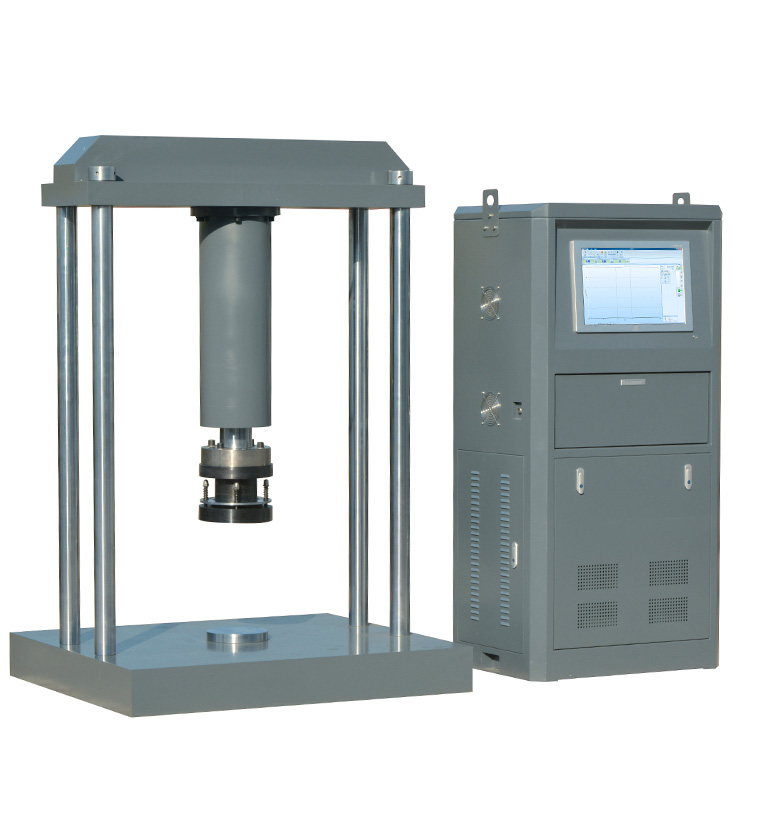

HJY-600B digital explicit manhole cover pressure tester

HJY-600B digital explicit manhole cover pressure tester

1. Microcomputer-controlled manhole cover pressure tester (upper pressure type) HJY-600B digital explicit manhole cover pressure tester Product introduction:

The JGW-600D microcomputer electro-hydraulic servo manhole cover pressure test machine is a high-precision material testing equipment that uses hydraulic power source drive, electro-hydraulic servo control technology, computer data acquisition and processing, and can realize closed-loop control and automatic detection. It consists of four parts: test host, oil source (hydraulic power source), measurement and control system, and test instrument. The maximum test force is 600kN, and the accuracy level of the test machine is better than level 1.

The JGW-600D micromechanical electro-hydraulic servo manhole cover pressure tester is used for the load bearing capacity (residual deformation and test load) test of manhole covers of various materials. It can realize closed-loop control such as equal rate loading and equal rate deformation, and can realize the automatic acquisition of technical indicators of the test piece.

2. Microcomputer controlled manhole cover pressure tester (upper pressure type) HJY-600B digital explicit manhole cover pressure tester complies withstandard:

GB/T23858-2009 "Inspecting the manhole cover"

GB/T26537-2011 "Steel fiber concrete inspection manhole cover"

CJ/T211-2005 "Inspecting manhole cover for polymer matrix composite materials"

CJ/T121—2000 "Inspecting manhole cover for recycled resin composite materials"

CJ/T3012 "Cast Iron Inspection Manhole Cover"

GB/T2611 "General Technical Requirements for Testing Machines" and GB/T16826 "Electro-hydraulic servo universal test machine"

3. Microcomputer-controlled manhole cover pressure tester (upper pressure type) HJY-600B digital explicit manhole cover pressure testerTechnical parameters:

model | JGW-600D |

Maximum force value | 600KN |

Measurement range | 1%-100%FS (full range is not divided) |

Deformation measurement resolution | 0.001mm |

Relative error | ≤±1% |

Maximum spacing of compression surfaces | 400 mm |

Effective distance between two columns | 1010mm |

Size of upper and lower pressure plates | Φ250×Φ356 mm |

Piston stroke | 400mm |

Maximum speed of piston movement | 120mm/mim |

External dimensions | 1220×1050×1900mm |

Dimensions (control cabinet) | 800×600×1600mm |

power supply | 380V |

The power of the whole machine | 1.8kW (oil pump motor 1.5kW) |

Oil source cabinet weight | 300kg |

Host weight | 2500kg |

Recommended informationNEWS

- [2022-07-29]Staff must conduct necessary inspections on the different structures and parts of the fatigue testing machine

- [2022-07-29]In practical applications, friction between parts is inevitable.

- [2022-07-29]Methods to avoid positioning errors of electronic universal test machines

- [2022-07-29]What errors are prone to occur when using the fatigue test machine

- [2022-07-29]Performance characteristics of electronic universal testing machine and preparations before operation

- [2022-07-20]What are the safety and service life of the woven bag tensile tester?

- [2022-07-20]Several categories of tension machine sensors

- [2022-07-20]Calibration of universal testing machine sensor

- [2022-07-20]Introduction to technical problems of material tensile testing machine

- [2022-07-15]Handling of displacement system failure of tensile test machine

- [2022-07-15]Low temperature impact tester

- [2022-07-15]How to choose a horizontal tensile tester and what to note during experiments

- [2022-07-13]Tips for using universal testing machine

- [2022-07-13]About how to choose a high-precision material testing machine

- [2022-07-08]Impact sample notch hydraulic pulling bed (US standard)

- [2022-07-08]Wide application and precautions for stripping test machines

- [2022-07-08]Common problems and solutions during the use of universal thermal insulation test machine

- [2022-07-08]Test method for rock wool shear strength