Constant temperature and humidity testing machines have been widely used in the fields of electronics industry, national defense technology, chemical electronics, mechanical manufacturing, aerospace, etc., and have received unanimous praise. So how do constant temperature and humidity test machines maintain and clean and maintain them in their daily work? Below is our technicians summarized about the maintenance and cleaning and maintenance of constant temperature and humidity test machines. What do you know? I hope it can help everyone.

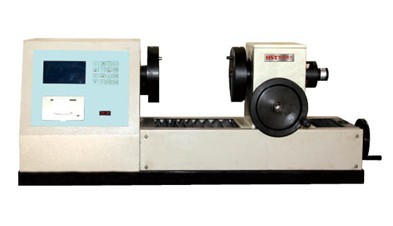

![What do you know about the maintenance, cleaning and maintenance of constant temperature and humidity testing machines - [Information]](http://www.hssdtest.com/uploads/image/20250418/58/47af741b4c004593b5e39310390af406.jpg)

1. Cleaning and maintenance of the internal and external body of the constant temperature and humidity test machine

1) The constant temperature and humidity test machine should remove internal impurities before operation.

2) Clean the distribution room at least once a year. When cleaning, you can use a vacuum cleaner to suck out the indoor dust.

3) The outside of the body must also be cleaned more than once a year. Wipe it with soapy water first during cleaning.

2. Inspection and maintenance of humidifier of constant temperature and humidity tester

The water storage in the humidifier should be replaced once a month to ensure clean water quality. The humidified water tray should be cleaned once a month to ensure smooth water flow.

3. Check the overtemperature protector for constant temperature and humidity test machine

When the constant temperature and humidity test machine is running, the set value of overtemperature protection is increased by 20℃~30℃. When the temperature in the test machine rises to the set point of overtemperature protection, the power supply of the heater will stop. The "OVERHEAT" overtemperature warning light is on but the fan is still running. If it is running for a long time and is unattended, be sure to check the overtemperature protector before operation to see if it is set properly [the setting of the wet ball overtemperature protector is 120℃].

4. Cleaning of dust in the condenser of constant temperature and humidity test machine

The condenser should be maintained regularly and monthly, and the dust attached to the condenser heat dissipation mesh should be sucked away by using a vacuum cleaner or sprayed with high-pressure air to remove dust.

5. Replacement of wet ball test cloth for constant temperature and humidity testing machine

When the surface of the test cloth is not clean or hard, or after the temperature control is completed, the test cloth must be replaced before continuing to control the temperature and humidity bulb. The test cloth should be replaced every three months. When replacing it, use a cleaning cloth to wipe the temperature measuring body [Sen-sor]. When replacing the new test cloth, clean it first.

6. Inspection and adjustment of wet bulb water level in constant temperature and humidity test machine

The water level of the water tank should not be too high, so that the water overflows the water tank or is too low, so that the wet bulb test cloth absorbs water abnormally, affecting the accuracy of the wet bulb. The water level should be kept about six minutes full. Adjusting the water level of the water tank can adjust the height of the water tank.

The above is about the maintenance, cleaning and maintenance of constant temperature and humidity testing machines. What do you know about? I hope it can help you. During use, you must pay attention to the maintenance of the machine and regularly check and maintain the integrity of parts and components. Pay attention to applying anti-rust oil to parts that are prone to rust or accessories that are not used for a long time, so as to extend the service life of the machine.

Alibaba CMO Dong Benhong publicly interprets all media for the first time, new retail drives digital transformation of business

![What do you know about the maintenance, cleaning and maintenance of constant temperature and humidity testing machines - [Information]](http://www.hssdtest.com/uploads/image/20250418/58/47af741b4c004593b5e39310390af406.jpg)