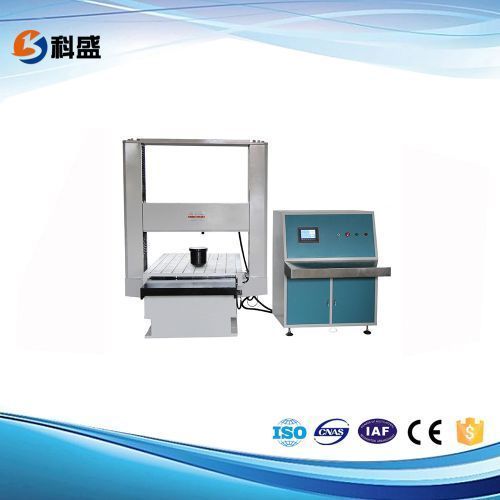

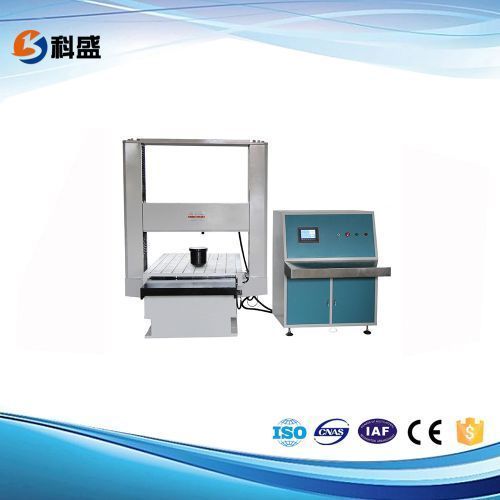

Fatigue testing machine is a widely used equipment among many testing instruments. It mainly measures the fatigue properties of various materials and understands its application value. However, there are many types of fatigue testing machines, and different testing machines have different functions and values. For example, spring fatigue testing machines, mainly testing instruments that measure spring materials. Below, our technicians will introduce to you the principles and maintenance of the fatigue testing machine.

The fatigue tester works according to the principle of electromagnetic resonance and applies loads based on the oscillation of the electromagnet. It is currently the first choice for the relatively large load of 20KN-300KN and the frequency of 80-250HZ. The frequency needs to be adjusted, and the frequency is fixed at several times. According to the feedback from customers at present, frequency regulation is more troublesome.

After the fatigue testing machine is equipped with the corresponding test fixture, it can perform three-point bending test, four-point bending test, thin plate tensile test, thick plate tensile test, reinforced steel strip tensile test, chain tensile test, firm joint test, connecting rod test, torsion fatigue test, bending and torsion composite fatigue test, interactive bending fatigue test, CT test, CCT test, and gear fatigue test.

Daily maintenance of fatigue testing machine

1. In normal working state, the error of the spring tester needs to be checked once, and its effective period is one year. Error verification is a very important task. Only by accurately verifying can the measured data be accurate and accurate. On the contrary, if the calibration work is not formal, it will affect the measurement of the test machine and cannot meet people's measurement needs.

2. During the operation of the spring test machine, you must pay attention to the unloading issue. Do not let go suddenly when unloading, as this will cause strong vibrations in the equipment and affect the accuracy of the test machine.

3. Lubricating oil should be added frequently to the lift rack and oil cup of the fatigue tester to ensure that the tester will not crash frequently. The main function of lubricating oil is to ensure better operation of the equipment and improve the operating efficiency of the equipment.

4. If the fatigue test machine is finished, it should be protected and coated with a machine clothes to prevent dust from falling into the equipment, affecting the normal use of the equipment, and reducing the service life of the equipment.

5. After the necrosis of the fatigue test machine, it should be properly protected and safely grounded to ensure its use standard and accurately measure data information.

6. The fatigue test machine must be cleaned regularly. Due to the long-term working of the equipment, the equipment will contain a large amount of dust, which will affect the normal measurement of the equipment. If the dust is not cleaned for a long time, it will definitely bring a measurement burden to the equipment and affect the accuracy of the equipment's measurement.

The above is about the principles and maintenance of the fatigue test machine. Everything needs to be maintained to extend its service life. Therefore, when using the test machine, you must not ignore the importance of maintenance, so that the service life of the test machine can be extended and the equipment measures accurate data for people's reference.

Earn a year with one day? ! Please check your consumer assets