News

Development trends and functions of universal material tensile testing machine

Release time:2019-09-10 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

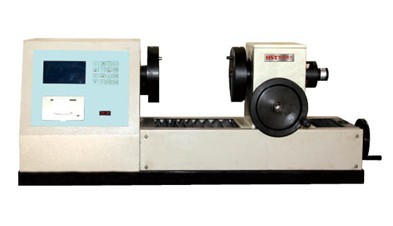

The universal material tensile testing machine is suitable for static mechanical properties testing and analysis of metals (including composite materials), rubber and plastics, and adhesive materials. How much do you know about the universal material tensile testing machine? The following editor will introduce to you the development trends and functions of the universal material tensile testing machine.

1. Development trend of universal material tensile testing machine

Currently, the most common items tested using universal material tensile testing machines are tensile strength and tensile modulus, tortuous strength and modulus. When performing tensile experiments in accordance with ASTM D 638 and ISO 527, there are clamps on both ends of the spline. One clamp is aborted and the other is fixed on the cross head, which moves against the fixing clamp, and pulls the spline until the spline cracks. The cross head will actively abort when it cracks. During the tortuous experiment (ASTM D790, D6272 and ISO178), the splines were placed on the two supporters of the test machine fixed machine tool. In this experiment, the direction of the crosshead movement is opposite to the direction of movement in the tensile experiment, pushing towards a center without support instead of traction of the spline until the spline is tortuous or even cracked. Since most thermoplastic materials will not crack in this experiment, it is impossible to calculate the cracking tortuous strength. Therefore, standardized experimental methods require accounting for tortuous stress when the strain is 5%.

Compared with tensile testing machines, the application fields of universal material tensile testing machines are becoming more and more extensive, and the demand for tensile testing machines in the market is also expanding, bringing broader development prospects to the development of tensile testing machines. Judging from the current development prospects of tensile testing machines, the technical level of domestic testing machine testing equipment is still far from that of foreign advanced equipment. The lack of core technology is enough to restrict the development of the domestic testing machine market. At the same time, among the high-end test machines that have been put into use in my country, there are still quite a few first-class equipment that rely on imports, which makes the domestic test machine market always passive and cannot completely base itself on the international test machine market.

Therefore, if China's universal tensile testing machine wants to be based in the international market, the company itself must have a core technical research team. At present, many new fields have been increasingly valued by all walks of life, and the testing machine industry has also begun to participate in these new fields. At present, the development of some new industries has successfully promoted the development of the testing machine industry. The vigorous development of the new fields has not only driven the increase in the production capacity of the testing machine, but more urgently, it is necessary for the testing machine market to develop more new equipment in order to achieve common development and development of the testing machine and new fields, and achieve mutual benefit and win-win results.

2. Functions of universal material tensile testing machine

1. Testing and data processing can be carried out according to various standards such as GB, ISO, ASTM, JIS, etc.

2. Suitable for the testing centers of colleges and universities, research institutes, import and export commodity inspection bureaus, quality inspection bureaus, construction and construction materials inspection stations and other units to conduct a number of physical and mechanical performance tests on metals, non-metals, composite materials and products.

3. It can be widely used in aerospace, petrochemical, automobile parts, engineering plastics, wires, cables, plastic rubber, textiles, ceramics, building materials, metal materials, polymer materials, waterproof materials, food and pharmaceutical packaging industries and other industries.

4. The tensile strength, compression strength, bending strength, elongation at break, elastic modulus, stress, strain and other parameters of the material can be measured. (Determine which kind of test to do according to the specific requirements of the user)

5. Wide expansion of force value: equipped with high-precision sensors, wide expansion of test range.

6. Optional deformation measurement: equipped with a large deformation measurement device to make the measurement elongation accurate.

Mechanical equipment is essentially the same. The coordinated operation of different components can only make the entire experimental process smoother and the experimental data more accurate. To sum up, the development trend and functions of the universal material tensile tester are related to the development trend and functions of the universal material tensile tester. I hope it can help you.

- Previous article:Performance and use of metallographic microscopes

- Next article:Uses and functions of electronic tension testing machine

Recommended productsPRODUCTS