News

Uses and functions of electronic tension testing machine

Release time:2019-09-10 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

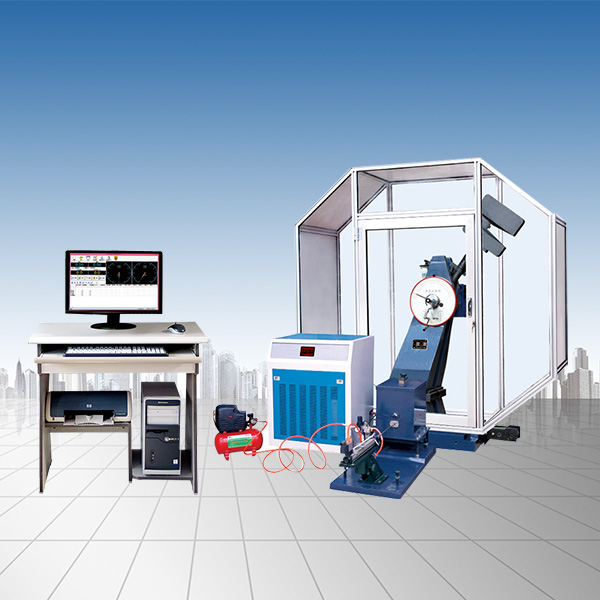

Electronic tensile testing machine, also known as electronic tensile machine, is suitable for performance testing of plastic films, composite materials, adhesives, adhesive tapes, self-adhesives, medical patches, protective films, release paper, back plate materials, rubber, paper fibers and other products, stretching, peeling, deformation, tearing, heat sealing, adhesive, puncture force, opening force, low-speed unwinding force, etc. Let me introduce the use and functions of the electronic tensile testing machine.

1. Use of electronic tensile testing machine

The electronic test tension test machine uses a stepper motor as the power source. The microcomputer displays the test data and test status in real time. The control of the test process is achieved through the automatic control of the microcomputer. Electronic tensile testing machine can force various non-metallic materials and composite materials

Academic performance testing and analysis research, widely used in aerospace, petrochemical, machinery manufacturing, wires, cables, textiles, fibers, plastics, rubber, ceramics, food, pharmaceutical packaging, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, wood, paper and other manufacturing industries.

2. Functions of electronic tension testing machine

Technical indicators:

1) Maximum test force of sensor: 10KN, 20KN (optional)

2) Accurate measurement range of test force: 2% to 100%

3) Test force measurement accuracy: ±1%

4) Displacement resolution: 0.01mm;

5) Displacement speed control range: 0.01mm/min to 500mm/min

6) Test space: 650mm;

7) Test space width: 370mm

8) Power supply power: 400W, 220V, 50Hz

Configuration:

1) Host one

2) Precision ball screws

3) A set of stretch fixtures

4) Stepper motor set

5) Stepping speed control drive system one set

6) Sensor 10KN, 20KN (optional) one

7) Control system one set

Electronic tensile testing machine Function introduction:

1) Automatic shutdown: After the sample is broken, the moving beam will automatically stop;

2) Automatic calibration: The system can automatically realize calibration of display accuracy;

3) Process implementation: The test process, measurement, display, etc. are all realized by a microcontroller;

4) Limit protection: It has two levels of limit protection for program control and mechanical;

5) Overload protection: When the load exceeds 3-5% of the maximum value of each gear, the machine will be automatically shut down.

6) The maximum test force value, break force value, yield force value can be recorded according to the corresponding standards; various strength values and other test data can be calculated.

To sum up, it is a related introduction to the functions and uses of the electronic tensile tester. Before using any tester, you must fully understand the product so that you can better achieve human-machine running-in during operation. This improves production efficiency. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer them one by one. Welcome to call and support!

Recommended productsPRODUCTS