News

Characteristics and operation methods of simple-supported beam impact test machine

Release time:2019-09-25 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

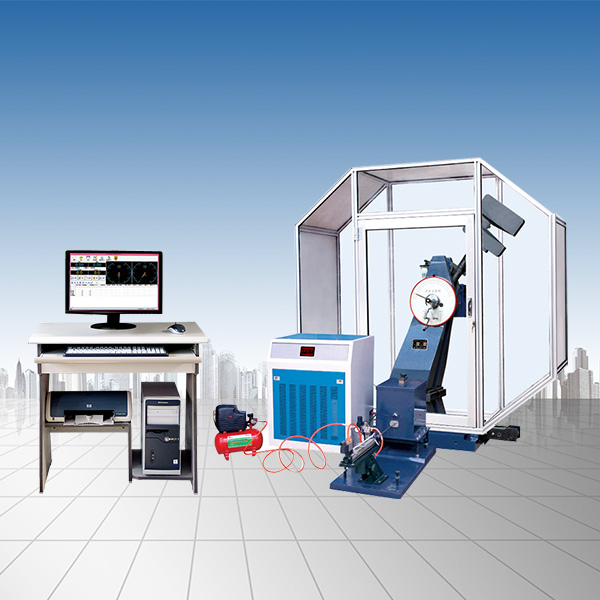

The simple-supported beam impact testing machine is a commonly used material testing machine, mainly used for the determination of impact toughness of hard plastics (including plates, pipes, plastic profiles), enhanced nylon, fiberglass, ceramics, cast stone, electrically insulating materials, etc. It is an ideal testing equipment for the chemical industry, scientific research units, college quality inspection and other departments. This time I will introduce the characteristics and operating methods of the simple-supported beam impact test machine.

1. Characteristics of simple-supported beam impact test machine

1. Customization; professional customization can be implemented according to the use areas of different industries, and different enterprises and industries can produce according to their own required parameters.

2. Cost; The service life of the simple-supported beam impact tester is 8-10 years. Purchase a simple-supported beam impact tester, which will be relatively large in the short term, but will have an average life span of ten years.

3. Environmental protection; Sustainable development is a requirement of economic development and a reflection of social civilization. The product is not only environmentally friendly and has a long service life. After the used waste simple-support beam impact test machine is recycled and processed by modification, the products produced can be used in other industrial production fields.

4. Performance; the production method and structure of the simple-supported beam impact tester product determine the reliability of performance. The simple-supported beam impact tester and the cantilever beam impact tester are relatively flexible in operation, with simple structure, convenient operation, reliable performance, light and smooth weight.

2. Operation method of simple-supported beam impact test machine

1. Replace the appropriate pendulum according to the impact energy requirements before testing.

2. Turn on the power switch device and place the handheld operator to an empty (not a sample), check whether the passive dialing pointer refers to zero. If it is not a empty pointer, the position of the pointer should be adjusted, and the time and empty pointer is zero. Adjust the equipment before resetting the data displayed by the electronic test instrument.

3. The simple-supported beam impact tester dismisses the bearings at the edge of the swing block, and the gap affects the impact of the impact specimen gap supporting the center, such as the notch tension.

4. Press the "Start" button to promote the pendulum, set high and stable on site, the shipped cleaning machine swings all obstacles, and the maximum energy scale dial pointer.

5. The simple-supported beam impact tester presses the "test" button and hammers the sample. After the pendulum stops swinging, write down the impact of energy. After the test is completed, turn off the power operation and the impact of the machine power supply, bringing the operator back to the place.

6. Specific testing steps:

Raise the impact hammer to the alpha angle (150) and fix it to the fixing hook. The pointer is close to the pull rod, and the pointer should display 150 at this time. Press the fixed hook to allow the impact hammer to fall freely and push the sample. Reading index indicates the β angle sum record. Without samples, from the alpha angle, the hammer will affect the sum of the reading pointer indicating the alpha angle. There is no sample because the β angle will affect the hammer drop, read the pointer indicating the angle β and record. There is no sample, the effect of the hammer from the α angle. Do not move the cursor, so that the impact hammer falls freely, and the pointer will rise again, repeat this way until the index does not move anymore; record the angle θ and record the index represented by the index.

Mechanical equipment is essentially the same. The coordinated operation of different components can only make the entire experimental process smoother and the experimental data more accurate. In summary, it is a detailed introduction to the characteristics and operating methods of the simple-supported beam impact tester. I hope it can help you.

Recommended productsPRODUCTS