News

Maintenance and use precautions for universal testing machine

Release time:2019-10-21 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

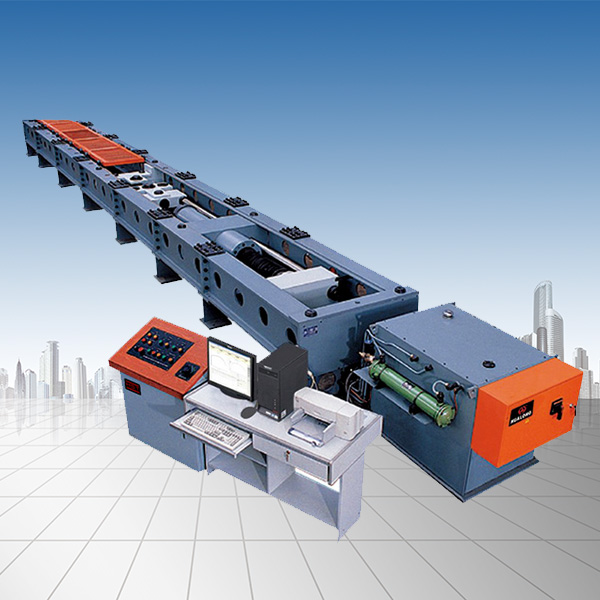

The universal testing machine is a material testing machine that integrates tensile, bending, compression, shear, ring stiffness and other functions. It is mainly used for mechanical properties tests of metal and non-metallic materials. It is an ideal testing equipment for industrial and mining enterprises, scientific research institutions, colleges and universities, engineering quality supervision stations and other departments. Below, we will introduce the maintenance and use precautions of universal testing machines.

1. Maintenance of universal testing machine

Maintenance of universal testing machine equipment:

1. The fixtures equipped with the machine should be coated with anti-rust oil for storage;

2. Since the jaws of the hydraulic universal testing machine are often used, they are prone to wear and tear. When there is too much oxide scale, it is easy to cause damage to the small piston and oil leakage. Therefore, the jaws should be cleaned frequently and kept clean (it is best to clean after each test);

3. The sliding surfaces in which the steel plate inset and the lining plate and the dovetail groove surface on the lining plate should be kept clean, and a thin layer of MoS2 (molybdenum disulfide) grease should be applied regularly;

4. Check the screws in the jaw area regularly. If they are found to be loose, tighten them in time;

5. Check the transmission status of the sprocket regularly. If you find loose, please re-tension the tensioner;

Maintenance of equipment oil source:

1. Regularly check whether there is any oil leakage at the main engine and oil source. If there is oil leakage, the sealing ring or combination gasket should be replaced in time;

2. Regularly replace the oil suction filter and filter element according to the use of the machine and the service life of the oil, and replace the hydraulic oil.

3. When not doing tests for a long time, be careful to turn off the mains power supply. If the machine is in standby state, the switch should be turned to the "load" setting, because if the switch is turned to the "quick reversal" setting, the solenoid reversing valve is always in the power-on state, which will affect the service life of the device.

Equipment control system maintenance:

1. Regularly check whether the connection wire on the rear panel of the controller is in good contact. If it is loose, it should be tightened in time;

2. If you do not use the machine for a long time after the test, turn off the controller and computer;

3. The interfaces on the controller are one-to-one, and plugging in the wrong interface may cause damage to the device;

4. The interface on the plug-in and unplug the controller must be powered off.

2. Precautions for the use of universal testing machine

1. Any product will cause collision vibration due to transportation, use, storage, and causing defects in the product at a certain period of time.

2. In many products, due to habits, many products are bad at this time, or even just exceeded the warranty period, or are a little difficult to find due to low value or service. How many manufacturers know about the bad criticism of the product for the brand?

3. If you can truly design and production, quality can help you display the shortcomings that you cannot see in the product and then improve it. for example:

1) The design is to analyze broken loop points and prone to bad points

2) When it comes to quality, different prone defects generated by each batch of flash can be analyzed.

3) During production, it can be measured completely while vibrating, so that the product defect rate can be detected early

4) Durability measurement, allowing the product to be used durable and improve the components that are not durable in advance, and the company's brand reputation will be better.

After understanding the maintenance and use precautions of universal testing machines, the operator must use them in accordance with the procedures and specifications of the instructions when using the testing machines. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation.

Recommended productsPRODUCTS