News

Do you know the main things about impact testing machines and how to self-test?

Release time:2020-11-26 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

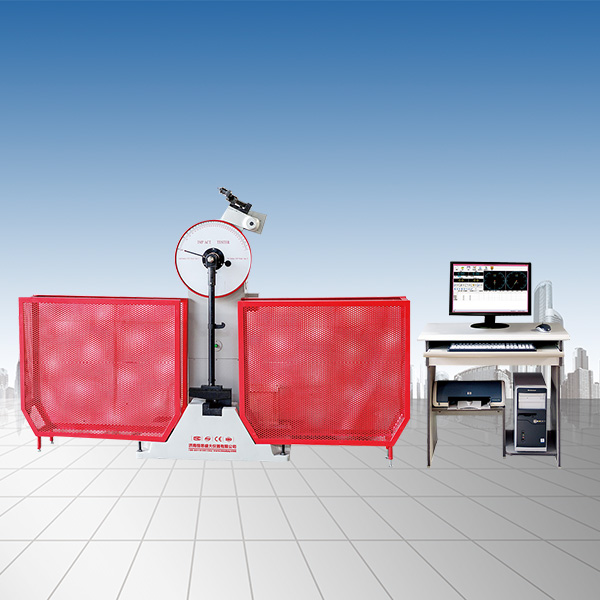

An impact tester refers to a material testing machine that applies impact test force to the sample and performs impact test. The impact testing machine is divided into manual pendulum impact testing machine, semi-automatic impact testing machine, digital impact testing machine, microcomputer controlled impact testing machine, drop hammer impact testing machine, and non-metal impact testing machine. Tests in two forms of simple support beam and cantilever beam can be achieved by replacing the pendulum and sample base. So do you know the main things and how to self-test the impact test machine? Let’s take a look with the editor.

1. Precautions for impact testing machine

1. Pay attention to protecting the rocker arm during operation. Do not place objects of the same height on the edge of the experiment machine to avoid collision with the rocker arm.

2. The level should be corrected before use. Once the level is corrected, no movement is allowed at will to ensure its level.

3. The size of the test sample of the impact test machine should be strictly as specified above to avoid damage to the impact arm.

4. The impact blade should be hit on the entire width line of the sample, and the impact blade should be aligned with the center line of the sample.

5. Pay attention to maintaining lubrication in the connection area.

6. Before the test, you should check whether all institutions are normal and that the range of movement of the pendulum must not be obstructed to avoid accidents during impact.

7. When the impact test machine is conducting impact tests on high-speed steel and steels of similar properties, it must be equipped with a safety cover to prevent the sample from flying out and injuring people.

2. Self-test method of impact testing machine

1. When performing tensile experiments, the sample fracture is always broken on both sides. The jaws should not be placed in a straight position when clamping, and the jaws should be clamped symmetrically as required. The jaws are of low quality and damage to the teeth. In addition to affecting the jaws, the sample is slipped during the experiment, making it difficult to identify the yield point. The jaws should be replaced at this time.

2. The dial pointer has poor sensitivity, the pendulum orientation is abnormal, and the swing rod of the impact tester is prohibited from being straight.

3. The impact test machine hammer returns to position abnormally, sometimes fast and sometimes slow. The forced needle cannot stop well in any direction, and does not coincide with the main needle. After the sample cracks, the pendulum quickly falls back, forming an impact. The lifting guide wheel is not properly conditioned, causing the upper and lower jaws to be different from each other. A test rod should be processed, and after the upper and lower jaws are tightened, use two force columns as the basis to measure with a dial until the conditioning is qualified. Replace oil with appropriate viscosity.

4. When loading, the oil leakage in the oil circuit system may break. Check whether the joints of the oil circuit system are tightened. If you need to replace the gasket, replace it in time. If the oil pipe breaks, check whether the joints of the oil circuit system are tightened. If you need to replace the gasket, replace it in time. If the oil pipe breaks, then you need to replace the oil pipe with higher strength. In addition, you need to investigate whether the oil supply valve and relief valve piston are pressed or installed in reverse.

5. If the temperature rises very slowly, you need to check the air circulation system to see if the conditioning baffle of the air circulation is open and normal. Otherwise, check whether the motor operation of the air circulation is normal. If the temperature is overshooting fiercely, then the setting parameters of the PID need to be adjusted. If the temperature rises directly and is protected by overtemperature, if the controller has problems, the control instrument must be replaced.

6. If the low temperature of the high and low temperature impact test machine does not meet the experimental policy, then you have to investigate the temperature change. It is because the temperature drops very slowly, or the temperature has a tendency to rise after the temperature reaches a certain value. The former should check whether the work room is dried before performing a low temperature experiment, so that the work room can't dry it, and then put the experimental samples into the work room before doing the experiment. Whether the experimental samples in the work room are placed too much, so that the wind in the work room cannot be fully circulated. After removing the above reasons of the high and low temperature impact test machine, you must consider whether it is a problem in the refrigeration system, so that professionals from the manufacturer must be asked to repair it. The latter appearance is caused by the poor application environment of the equipment. The ambient temperature of the equipment and the position of the equipment (the distance between the box and the wall) must meet the needs (there are rules in the equipment operation instructions).

7. The actual humidity will reach 100%. The practical humidity may be very different from the policy humidity. The value of the high and low temperature impact test machine is much lower. The appearance of the former: it may be caused by the boring gauze on the wet ball sensor. Then check whether there is water shortage in the sink of the wet ball sensor. The water level in the sink of the high and low temperature impact test machine is automatically controlled by a water level operator. Check whether the water level operator water supply system is normal and whether the water level operator operation is normal. It may be that the wet-ball gauze is hard due to the long use of or the purity of the water supply, making the gauze hard, making it impossible to absorb water and become boring. Just replace or clean the gauze to remove the above appearance. The latter's appearance is mainly that the humidification system does not work. Check the water supply system of the humidification system, whether there is a certain amount of water in the water supply system, whether the water level control of the water level of the humidification boiler is normal, and whether the water level in the humidification boiler is normal. If all the above is normal, then check the high and low temperature impact test mechanical and electrical control system, and ask professional repair personnel to do the repair.

8. The corresponding fault display prompt appears on the control instrument and there is a sound alarm prompt. The operator can quickly check which type of problem is derived from in accordance with the problems in the operation and use of the equipment, and ask professionals to quickly eliminate the problem to ensure the normal progress of the experiment. Other environmental high and low temperature impact testing machines will have other appearances during use, so the appearance needs to be detailed, analyzed and swept.

9. The environmental experimental equipment of the impact test machine must also be protected and maintained regularly, the condenser of the refrigeration system must be organized regularly, and the moving parts should be refueled smoothly according to the instructions, and the high and low temperature impact test machine and electrical control system must be protected and viewed regularly, etc. These operations are essential.

The above are the main things of the impact test machine shared by the editor and how to self-test it hopes to help everyone!

Recommended productsPRODUCTS