News

Waterproof coil tensile tear test

Release time:2022-06-17 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The basic functions of waterproof material testing machine and tensile testing machine: tensile performance, tensile strength and deformation rate, tensile breaking force, tear resistance, heat seal strength performance, roller peeling test, 90 degree peeling, rope tension breaking force, trouser tear force, 180 degree peeling, compression test, bending test, shear test, top break test, etc. Complete different tests. According to different customer needs, different fixtures, wide sample fixtures, Japanese type fixtures, British type fixtures, etc. can meet the standards of multiple countries. Today, Kezhun editor will introduce to you how to perform tearing experiments on a waterproof coil tensile testing machine.

1. Principle of tensile tear test

1. The principle of the test is to measure the force required for the complete tearing of the specimen, which is the continuation of the existing notch or cut opening of the specimen. The waterproof coil tensile tester generates a uniform tearing force at a constant speed until the test piece is broken, recording the force at the highest point reached.

2. The waterproof coil tensile testing machine of instruments and equipment should have devices that continuously record forces and corresponding distances, and can separate the fixtures at speeds as specified below. The effective load range of the waterproof coil tensile tester is at least 2000N, the tension speed of the fixture is (100 nm I0) mm/min, and the clamping width is no less than 50mm. Suzhou Kezhun Testing and Control Co., Ltd. can easily complete this test. The fixture of the waterproof coil tensile tester can maintain or increase the clamping force of the fixture as the tension of the test piece increases. For products with a thickness of not more than 3mm, the specimen can be clamped so that its slippage in the fixture does not exceed 1mm, and the thicker products does not exceed 2mm. The specimen shows any slippage with a mark or tape at the fixture. The force measurement system meets JJG139-1999 at least 2 levels (i.e. 2%).

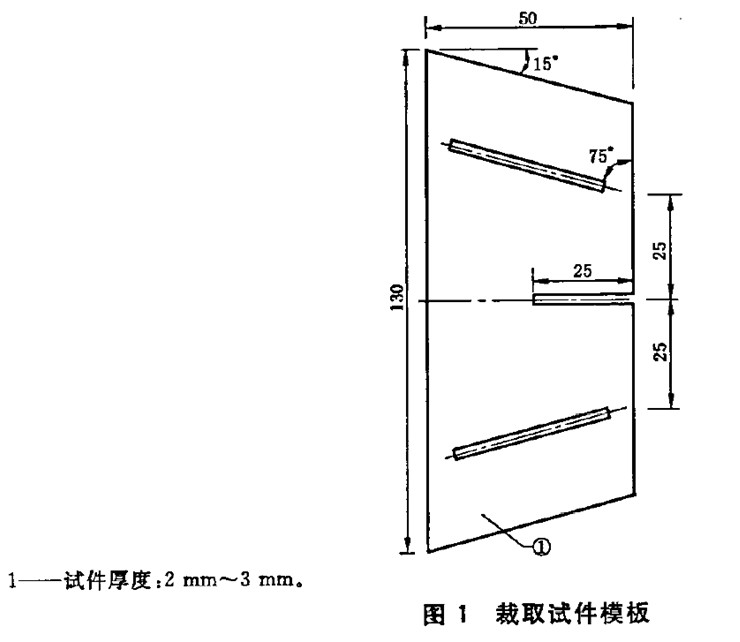

2. The template size of the cut specimen is shown in Figure 1

3. Test steps

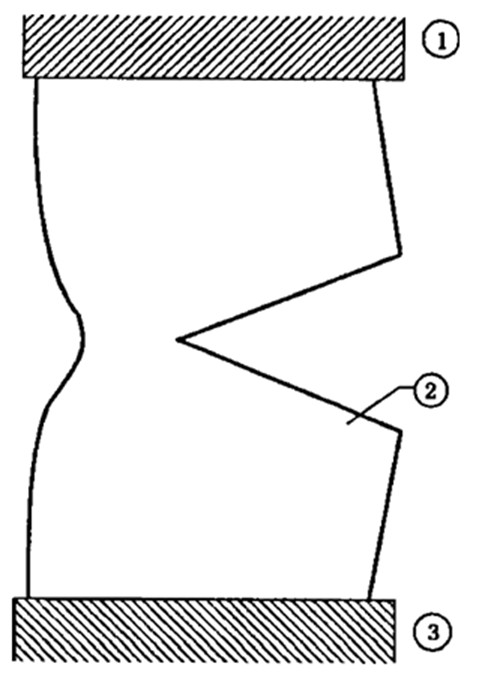

Step 1 The test piece should be tightly clamped in the fixture of the waterproof coil tensile tester, and be careful to keep the clamping line along the edge of the fixture (see the figure below). The test piece test temperature is (23 soil 2) C, and the tensile speed is (100 ns 10) mm/min. Record the maximum tension of each specimen.

1. Top fixture;

2. Test pieces;

3. Lower fixture.

4. Result representation

1. Calculate the maximum tension of each test piece and express it in N. The result of the test piece slipping from the waterproof coil tensile tester fixture exceeding the specified value, and re-test with spare parts to calculate the arithmetic average of tension (Fl and FT) in each direction, express it in N, and the result is 1N.

2. There is no regulation on the degree of the test method.

Recommended productsPRODUCTS