Company News

Aging of parts of universal testing machine and how to maintain and repair

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

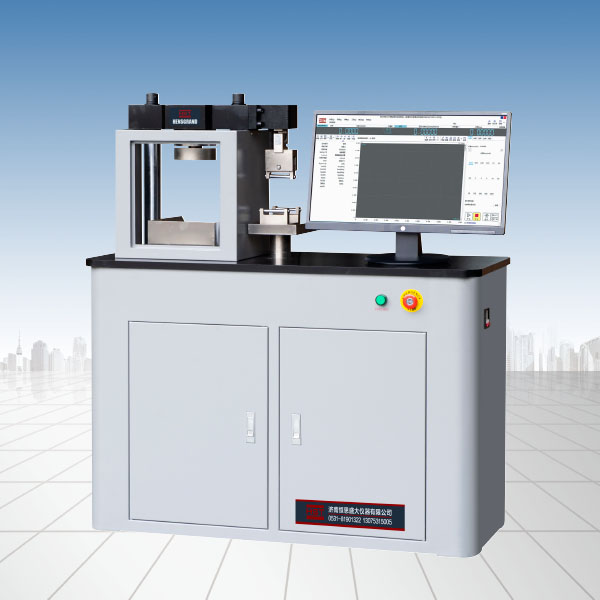

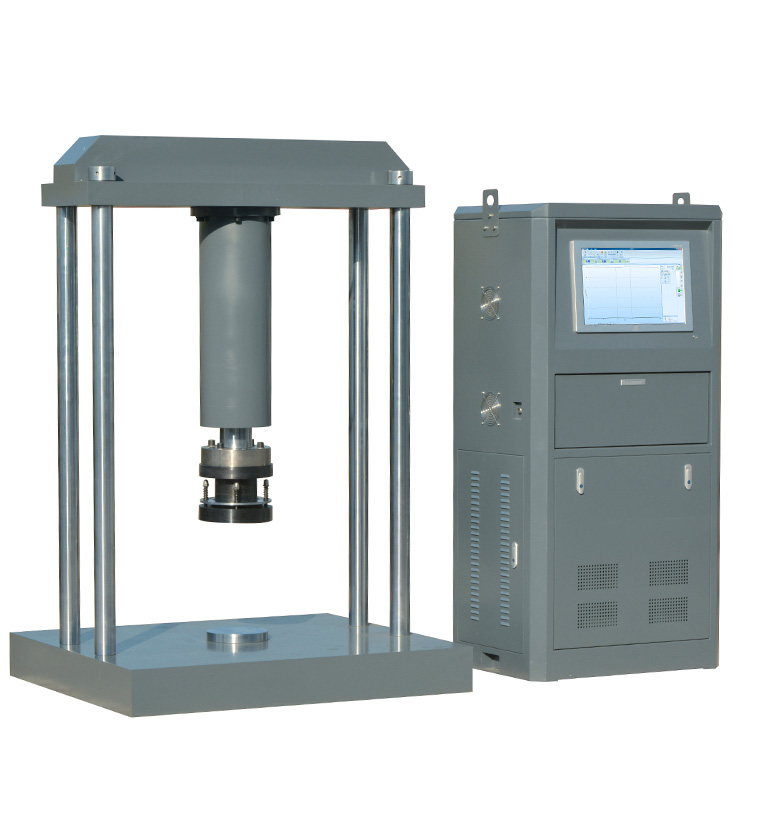

Universal testing machineDuring long-term operation, a series of problems will arise due to aging or improper maintenance of parts. Let’s summarize some possible failures and solutions to provide some help to users who are using them or those who are preparing to purchase:

Analysis of faults of universal testing machine:

The host does not start, check whether the power cord is connected properly and firmly.

Whether the three-phase 380 power supply is missing, check whether the power socket is missing, and whether the power cord of the ultrasonic flaw detector is off.

Whether the emergency stop button has been pressed or lifted.

Whether the limit switch is turned on or adjust the limit button to make it in the off state.

Has the sensor been knocked over, what is the initial force when powered on, and is there any obvious deformation of the ultrasonic flaw detection instrument sensor?

The zeroing parameters are changed, and the zeroing program is turned on for hardware zeroing.

Whether there is any false welding or disconnection of each solder joint or re-welding wire.

The force value jumps near a certain point and does not respond. Slip the fixture and choose the right fixture.

There is a section of the platform at the beginning of the curve. The load of the sample is not tightened. The value is set too small. The value is set to be larger and the platform is removed.

Solutions to faults of universal testing machine:

1) Whether the switching power supply is working normally, and measure the voltage at each output point of the switching power supply.

2) The host starts but does not operate, check whether the sensor connector is connected, and connect the sensor connector to re-plug and unplug the sensor connector.

3) Whether the communication line between the computer and the host is in poor contact or the center of gravity is connected to the communication line.

4) Whether there is any error message on the servo system. If an error is displayed, restart the host.

5) The force value is inaccurate. Whether the initialization parameters of the force sensor are called correctly and the initialization parameters consistent with the sensor are called again.

6) The force value calibration parameters have been changed and the force value is recalibrated.

7) The computer shows that "overload" or the force value cannot be adjusted, whether the sensor connector is completely connected, and the sensor is re-plugged and unplugged.

8) The force value parameter has been changed and the force value is recalibrated.http://www.hssdtest.com/

Recommended productsPRODUCTS