Company News

Extension meter

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1. Product Introduction

Extensometers are instruments used to measure the expansion and deformation of tiny lines of specimens. It generally consists of three basic parts, namely the feeling of deformation; the transfer and enlargement of the majority; and the display part. There are many types of extensometers, and now we introduce two commonly used ones.

II. Construction principle

The extensometer is composed of a dial gauge and a set of lever mechanisms composed of a ball hinge as a fulcrum. Hold the ball hinge extensometer with your hand, put the sample into the gauge fork, and clamp the specimen with a pointed screw to make the upper and lower gauge forks and the specimen integrated. Under the action of tension, the sample is elongated ΔL. During the deformation of the sample, the upper gauge distance fork does not rotate, while the lower gauge distance fork rotates at a slight angle due to the action of the ball hinge. The distance from the center of the ball hinge to the axis of the dial gauge rod is equal to twice the distance from the center of the ball hinge to the axis of the sample. Therefore, the deformation reading of the dial gauge is twice the length of the specimen axis within the gauge distance. Since the magnification of the dial gauge is 1000, the magnification of the extensometer is 2000. That is, when the ball-hinged extensometer dial gauge is moved one grid, the sample is stretched by 1/2000mm.

3. Operation steps and precautions

1. Adjust the extensometer gauge distance according to the actual needs of the measured sample size. Make the gauge of the extensometer equal to the gauge required for the measured sample.

2. Install the sample in the upper and lower chucks of the universal testing machine. When performing the elastic modulus test of the material, a certain initial load F0 can be applied to the sample (corresponding to 5% to 10% of the elastic deformation load). Then carefully install the extensometer on the sample to check whether the contact between the extensometer and the sample is appropriate and whether the dial pointer rotates flexibly.

3. After confirming that the test system is installed correctly, formal tests can be conducted.

4. Things to note

1) When the extensometer is installed on the sample, the longitudinal plane of symmetry of the instrument should be kept in the same plane as the axis of the sample as much as possible, and the gauge fork should not be significantly tilted left and right.

2) The actual deformation of the sample is not allowed to exceed the range of the extensometer, otherwise the extensometer will be damaged.

- Previous article:Introduction to the expert of hydraulic universal testing machine

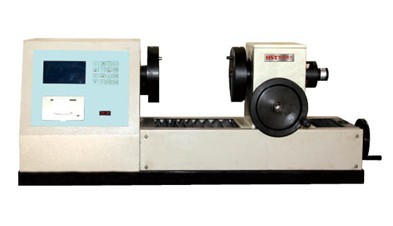

- Next article:Torsion test machine

Recommended productsPRODUCTS