Company News

How is the strength of the carton measured

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Box type refers to the type of box and the size ratio of the same type of box, which have a significant impact on compressive strength. Some carton boxes are made of double-layer corrugated cardboard, and the compressive strength is significantly improved compared with single-layer boxes of the same specifications; under the same conditions, the higher the box, the worse the stability and the lower the compressive strength. Cartons are made of corrugated cardboard with excessive moisture content, or stored in a humid environment for a long time, which will reduce their pressure resistance. Fiber is a kind of water-absorbing. In the rainy season and when the humidity in the air is high, the wet balance relationship between moisture in cardboard and the atmospheric environment is very important. During the box making process, improper pressure line, too deep grooves, and unstable bonding will also reduce the pressure resistance of the box. Place the carton into a hexagonal rotary drum equipped with an impact plate, rotate according to the specified number of rotations and times, and then check the damage of the goods and cartons. Dynamic experiments are all destructive, and improving the resistance of cartons and commodities is to use buffer pads, partitions or other protective measures when packaging goods. In addition, some packaging cartons also require spraying, weather resistance and other experiments, which can be agreed upon according to the contract agreement between the two parties. The carton is packaged with the goods and placed on the vibration table to cause them to be affected by horizontal and vertical vibrations, or to be subjected to bidirectional vibrations at the same time. After a certain period of time, check the product condition or the elapsed time when the carton of the goods is damaged.

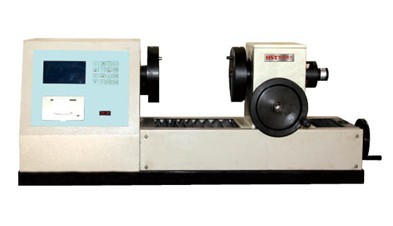

Usually, the inspection standards for testing carton strength have many requirements, such as appearance quality, printing quality, closure quality, dimensional tolerance, number of times of folding of covers, etc. Generally, the jointing specifications are required, the edges are neat and there is no corners. The box surface is not allowed to have obvious damage or stains, and the print is clear, the color is consistent, and the shiny is bright. Impact testing machine (recommended: tensile testing machine) The inner diameter and design dimension tolerance of the box should be kept at a large box ±5mm and a small box ±3mm. The shape and size are basically the same, there are no loopholes around the box body, and there is no jagged or gap after the covers of each box are closed. The printing position error is not more than 7mm, and the small box is not more than 4mm. The corrugated cardboard cover is folded back and forth by 180 degrees and folded more than 5 times. The total length of cracks in the surface layer and inner layer and inner layer of Class I and Class II boxes is not more than 70mm. During the test, the corrugated cardboard box is placed between the two pressure plates and the pressure when the carton is crushed is the pressure resistance of the carton, which is represented by KN.

Carton compressive strength has always been an important quality indicator for many commodity packaging requirements. Base paper is a decisive factor in determining the compression strength of cartons, which can be seen from the kellicutt formula. However, the impact of other conditions in the production process of corrugated cardboard is not allowed to be ignored, such as adhesive dosage, corrugated height variation immersion, coating, composite processing, etc. Cartons require a certain compressive strength because the carton stacked on the layer during storage and transportation after packaging the goods and is subject to the pressure of the upper carton. In order not to collapse, it must have a suitable compressive strength. The compressive strength of the carton is calculated by the following formula. Due to various factors in the production process, the compressive strength of the carton produced with raw materials is not necessarily exactly consistent with the estimation result. Therefore, the method to finally accurately determine the compressive strength of the corrugated carton is to treat the carton constant temperature and humidity and then use the carton compression tester to test it; for small and medium-sized factories without test equipment, a wooden board can be covered on the carton and then stacked an equal amount of heavy objects on the wooden board to roughly determine whether the compressive strength of the carton meets the requirements. There are many formulas to calculate the compressive strength of the carton based on the ring compressive strength of the base paper, but the more concise and practical is the kellicutt formula, which is suitable for estimating the compressive strength of the 0201 carton.

- Previous article:What is a torque sensor

- Next article:How to choose a mechanical testing machine

Recommended productsPRODUCTS