Company News

Detailed introduction to multiple sensors of the test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

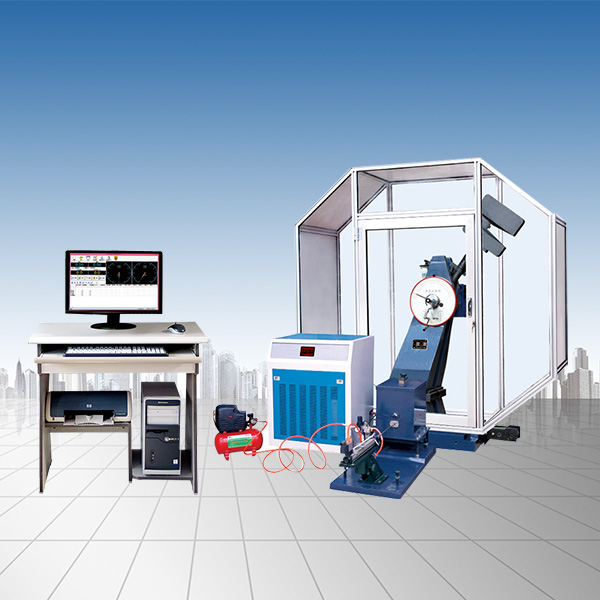

Testing machineWhat is important is the test results you are looking at. Inaccurate measurement data may sometimes be the reason for the sensor. It can be seen that the sensor is an important component of the test machine, but there are many types of sensors used in the test machine. The introduction of different sensors is different. The following is a detailed introduction to various sensors by Jinan Hengsi Shanda Instrument Co., Ltd.:

Resistance strain-type weighing force sensor: a sensor that has been thought of using local gravity acceleration and air buoyancy to measure mass. The weighing sensor can convert the measured mass into a voltage signal. There are various types of weighing sensors, such as capacitive weighing sensors, electromagnetic balance sensors, piezoelectric weighing sensors, etc. Definition of resistance strain gauge: a type based on strain-Made of resistance effect, the electronic universal test machine uses metal foil as a sensitive gate, and the sensitive element that can convert the strain value of the test part into the resistance transition value is called a resistance strain gauge.

Strain force sensor: A sensor that can convert various mechanical quantities into electricity is made of using resistive strain gauge as a sensitive component. Examples include tensile force, pressure, pressure, torque rejection, acceleration and other sensors.

Strain weighing sensor: A weighing sensor made of resistor tape as a sensitive component is called a strain weighing sensor. The relationship between strain-weighting force sensor and force sensor: Theoretically speaking, mass characterizes an entity's properties, whose measurement unit is kilograms, while mechanical quantities are a vector, and the measurement unit is Newton and other derived quantities, which has nothing to do with each other. But because mass is not measured directly, but is measured using the force effect of mass in the earth's gravity field, they are of the same kind as each other in terms of measurement skills. How to keep the specimen at the bottom of the machine is important because different types of tests require different fixtures, and changing fixtures is not only difficult to maintain consistency in position(This often affects test results), and it is easy to break the machine. The more delicate components are-Sensors are also a test of the strength of the experimenter. Many female experimenters find it difficult to complete this task. In addition, the price of fixtures is also relatively expensive. So, change the fixtures as little as possible. Some electronic universal testing machines are specifically designed for plasticsElectronic universal testing machine, it is designed to design the three-point bending fixture and the tensile fixture together, which reduces the process of replacing the fixture. Tensile test of electronic universal testing machine:Generally, the two ends of the material sample are clamped on two fixtures at a certain distance, and the two fixtures are separated and stretched at a certain speed to measure the stress changes on the sample until the sample is damaged.

Tensile test of tensile machines is one of the widely used methods to study the mechanical strength of materials, and requires constant speed movement. According to the different load measurement methods, it can be roughly divided into two categories: computer-type electronic universal testing machines and electronic universal testing machines. Currently, the electronic universal testing machines are mostly used.

The above areTesting machineThe introduction of the different sensors used is hoped that everyone can better distinguish the quality of the test machine.

- Previous article:10 Things to Do in Operation of Bending Test Machine

- Next article:Solution to the buffer problem of hydraulic universal machine

Recommended productsPRODUCTS