Company News

A careful understanding of the partition of materials testing machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

With the continuous development of technology, variousMaterial testing machineThere are endless emergence. The following is a detailed introduction to the division of material testing machines by Jinan Hengsi Shanda Instrument Co., Ltd.

The material testing machine can obtain a wide measurement range by staging it.

The analysis is carried out on the situation where the seven-speed range switching is performed using 13-bit A/D and the situation where the 18-bit A/D is not divided. Generally, the grading on the test machine is divided into 100%, 50%, 20%, 10%, 5%, 2%, and 1% of the full scale. For test machines that use 13-bit A/D, the resolution of each gear is ±1/4095 of the full value of each gear (the two-way pull and pressurize are divided into 4095 copies in both directions). Taking the test machine with 0.5-level accuracy as an example, according to the standard, the sampling code of its small effective measurement starting point should reach 400 codes, that is, it is about 10% of the full value of each gear. According to the above principles, the effective measurement value of the small gear of the test machine that uses the divided gear is 1%×10%=0.1%, and the overlap between each gear is greater than 10% of the full value of each gear, so the total effective measurement range can reach 0.1%-100%. For the case where 18-bit A/D is not divided, its resolution is ±1/131072 of the full value. According to the small effective measurement point, the sampling code should reach the requirement of 400 codes, and the small dot is (400/131072)×100%=0.3% of the full value.

1, , , , , can reduce the measurement error of small signals.

This just meets the requirements of the relative accuracy definition of the test machine. As we all know, the test data in the test machine comes from various sensors, and the current sensors are basically analog sensors, and the output signals are very weak. This signal must be amplified by the amplifier before it can be transferred to digital quantities by the A/D converter for post-processing. The essence of grading is to amplify the sensor output signals representing different ranges (of course the output values are also different) according to different amplifications to a unified set value, and then use this unified set value to represent different ranges. Take load as an example: If the full value output of a load sensor is 20mV, and after amplification of 125 times, it becomes the full value input of the A/D converter of 2.5V, then 2.5V represents the full value range of the load range. If the amplification factor is increased by 10 bits and becomes 1250 times, then when the sensor is subjected to 1/10 of the full value, that is, the output of the amplifier still reaches the full value input of the A/D converter of 2.5V, and at this time the load range is 1/10 of the full value. Since the working power supply of amplifiers and sensors are composed of various electronic components, they inevitably have various offsets and drifts. When the circuit is determined, these offsets and drifts will also depend on them, and they basically do not change with the change of the amplification factor. That is to say, the full value output of the amplifier is 2.5V consists of two parts, one is a real reflection of the actual measured value, and the other is a basically constant inherent value. When a small gear is selected, the measured value corresponding to this inherent value will decrease in proportion to the gear ratio. For example: When 2.5V corresponds to 100N, the inherent offset and drift of 0.1V will produce an error of 100×(0.1/2.5)=4N. However, if the 1/10 gear is selected, that is, when 2.5V corresponds to 10N, the inherent offset and drift of 0.1V will only produce an error of 10×(0.1/2.5)=0.4N. If the binning is not divided, this inherent error will not change regardless of whether the measured data value is large or small, and it is 100×(0.1/2.5)=4N, which is not conducive to measuring small signals.

Since the accuracy of the test machine requires relative accuracy, this accuracy has different allowable errors under different measurement values. The allowable error value is large when the measurement value is large, and the allowable error value is small when the measurement value is small. For example: when the load value of the same level is 0.5, when the measured value is 100N, the error value is 100×0.5%=0.5N, and when the measured value is 10N, the error value is 10×0.5%=0.05N. The characteristics of the grading are exactly consistent with this requirement.

Since the accuracy of the test machine requires relative accuracy, this accuracy has different allowable errors under different measurement values. The allowable error value is large when the measurement value is large, and the allowable error value is small when the measurement value is small. For example: when the load value of the same level is 0.5, when the measured value is 100N, the error value is 100×0.5%=0.5N, and when the measured value is 10N, the error value is 10×0.5%=0.05N. The characteristics of the grading are exactly consistent with this requirement.

2, Material Testing MachineGrading can reduce the requirements for sensors and improve the accuracy and reliability of the entire machine.This is very important in some special purpose test machines. The sampling speed of common test machines is not very high, which is about a range of dozens to hundreds of times per second. However, in some special purpose occasions, such as collision tests, impact tests, and brittle material tests, the sampling rate required is very high, ranging from thousands to several megabytes per second. Since the grading test machine generally chooses A/D with lower digits, there are many types of A/D in this type of A/D and a wide range of choices. There is a type of A/D with parallel conversion structure, which is very suitable for this occasion. For ungraded test machines, since high-position A/D is used, this type of A/D basically uses ∑-△ type converters, the conversion rate of this type of converter is relatively low, and the conversion accuracy will be significantly reduced when the conversion rate is increased.

3, , high-speed sampling is easy to achieve.This is very important in some special purpose test machines. The sampling speed of common test machines is not very high, which is about a range of dozens to hundreds of times per second. However, in some special purpose occasions, such as collision tests, impact tests, and brittle material tests, the sampling rate required is very high, ranging from thousands to several megabytes per second. Since the grading test machine generally chooses A/D with lower digits, there are many types of A/D in this type of A/D and a wide range of choices. There is a type of A/D with parallel conversion structure, which is very suitable for this occasion. For ungraded test machines, since high-position A/D is used, this type of A/D basically uses ∑-△ type converters, the conversion rate of this type of converter is relatively low, and the conversion accuracy will be significantly reduced when the conversion rate is increased.

4, , grading will cause inconsistent resolutions within the entire scale.

This seems to be a problem, but it has been discussed in the second item.Testing machineIn terms of the national standard, the national standard stipulates relative accuracy, which itself requires a high resolution of small gears and a low resolution of large gears, so it is not a problem for most uses. For example: weighing a car of coal does not require weighing a few tons or several grams, while weighing gold must reach a few thousandths of a grams.

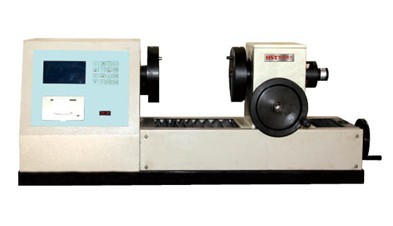

Tag: Universal Testing Machine, hydraulic universal testing machine, tensile testing machine, impact tester, twisting test machine, Material Testing Machine

Recommended productsPRODUCTS