Industry Information

Exploration on the shaft-degree survey method of universal material test equipment

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Tensile tests can be simplified to the model shown without considering the effect of articulation. At this time, the measurement error of the universal test machine mainly comes from the influence of additional bending. According to JJG139-1999, when coaxiality detection, first apply 1% of the test force and zero adjustment, then apply 4% of the test force to obtain the test. Therefore, the additional bending caused by the lateral binding force is not reflected in the coaxiality detection result. In addition, since ΔL max in JJG139-1999 is the deformation value of the larger side of the test sample in the same detection point in the same measurement, rather than the deformation value in the circumferential direction. Therefore, the measured coaxiality error of the test machine is not the test machine. In fact, the coaxial degree of the geometric universal material tester on the head of the electronic universal tester is a vector, which can be obtained by detecting two strains in two orthogonal directions of a commercial induction cooker.

The coaxiality detection method is modified and the standard coaxiality refers to the degree to which the measured axis should coincide with the reference axis, and the coaxiality error is the geometric quantity given in units of length. The evaluation standards given by the geometric method in JJG139-1999 comply with the agreements in the machinery manufacturing industry. In order to make the extensometer method in JJG139-1999 consistent with the geometric method, it can be obtained by appropriately modifying the judgment standard value. According to formula (2), the relationship between the coaxiality e and the geometric coaxiality δ of the extensometer method is e=8δ/d. The δ value is specified, and the allowable value of e is determined.

The measurement and calculation of coaxiality are assumed that δx and δy are the relative eccentricities of the upper and lower chucks of the test machine in the orthogonal directions, respectively, ΔL xmax and ΔL ymax are the strains of the larger side measured by the extensometer on the orthogonal directions of the mandrel. That is, the measurement of the geometric coaxiality of the test machine can be obtained by measuring the strain or stress in the orthogonal directions of the test mandrel. When measuring the strain, an extensometer can be used, and a three-component sensor can be used when measuring the stress. Conclusion According to the method proposed in this article, the geometric coaxiality of the test machine can not only objectively and scientifically detect the geometric coaxiality of the test machine, but also unify the evaluation standards of the two detection methods, which is of positive significance for the verification of the universal test machine.

- Previous article:Renovation and upgrading of electronic universal material testing machine

- Next article:May one day be as free as the wind

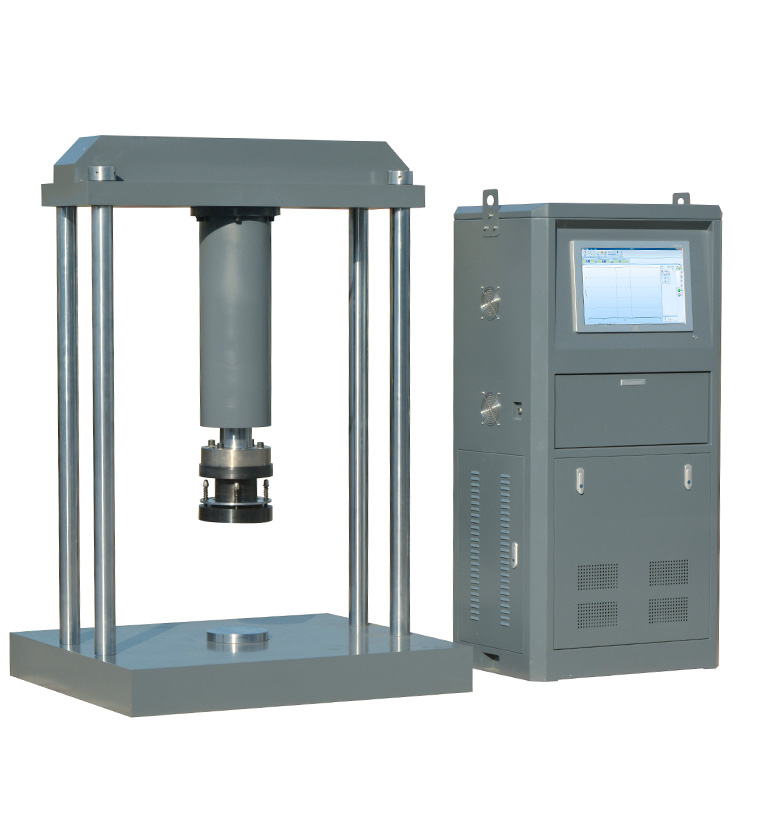

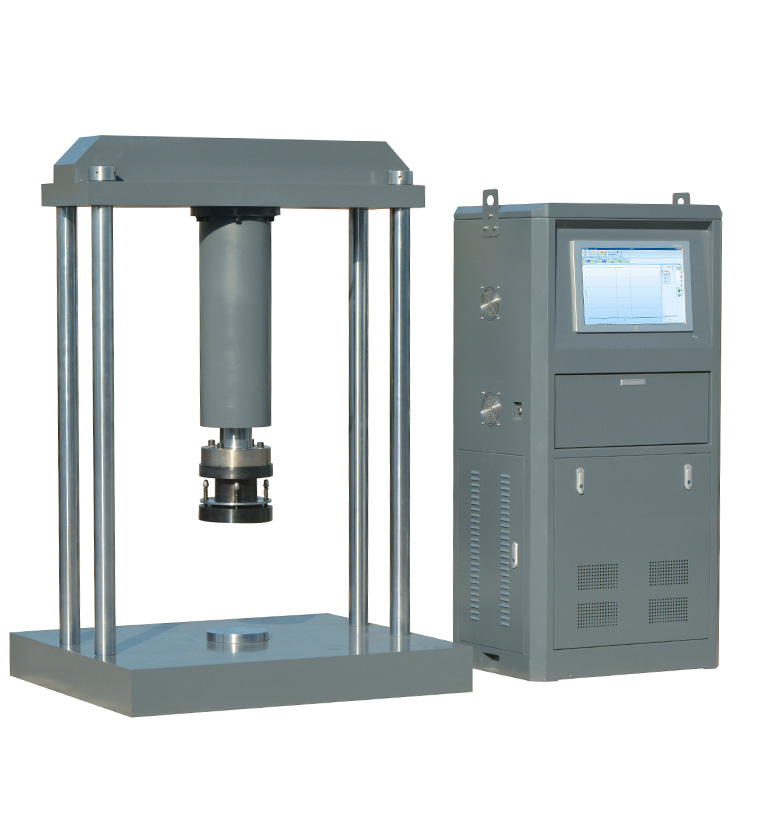

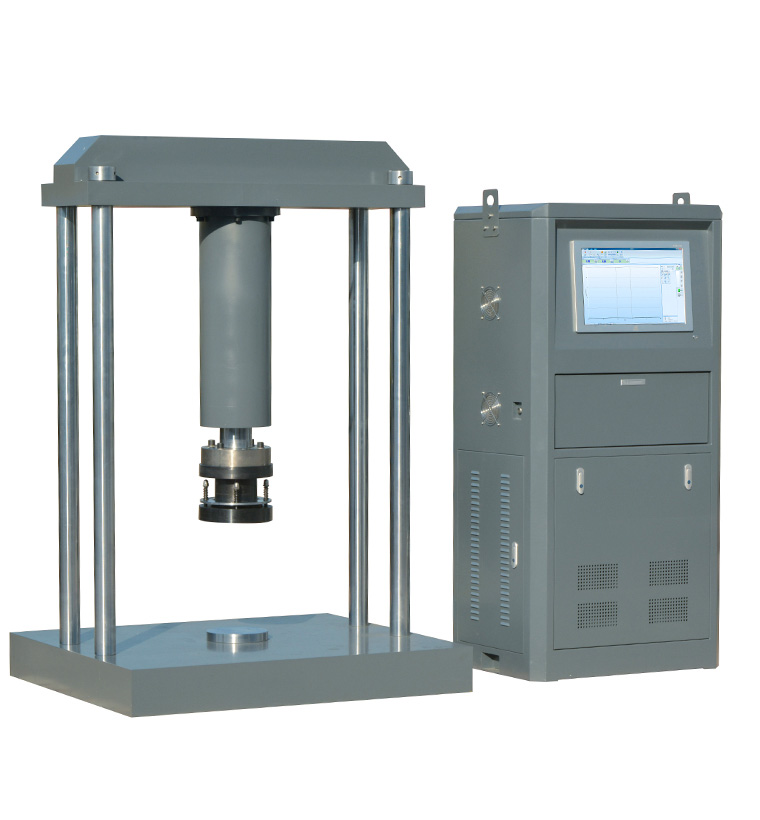

Recommended productsPRODUCTS