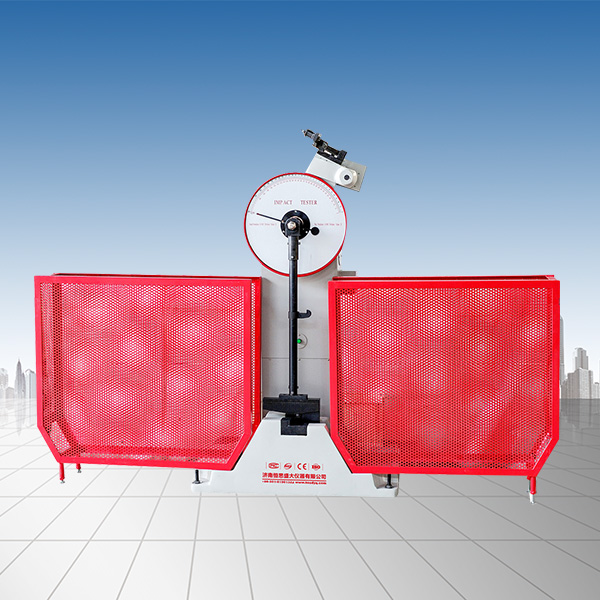

JB-500B semi-automatic impact tester

JB-500B semi-automatic impact tester

Functional uses

This machine is mainly used to measure the properties of metal materials to resist impact under dynamic loads, so as to judge the properties of the materials under dynamic loads.

This machine is a semi-automatic control test machine, which has simple operation and high working efficiency. It controls the swing, impact and discharge electrical appliances. It can use the remaining energy after the sample is broken to automatically prepare for the next test. It is especially suitable for laboratories that perform continuous impact tests and metallurgy, machinery manufacturing and other industries that perform large amounts of impact tests. The JB-500B impact test machine complies with the national standard GB/T3808-2002 "Inspection of Pendulum Impact Test Machine", and the impact test of metal materials is carried out in accordance with the national standard GB/T229-2007 "Metal Shabi Pendulum Impact Test Method".

Technical parameters

1. Impact energy: 250J, 500J

2. Pre-raising angle of pendulum: 150°

3. Distance from the center of the swing shaft to the impact point: 800mm

4. Impact speed: 5.4m/s

5. Span of the sample bearing: 40mm

6. Claw fillet: R1-1.5mm

7. Impact blade rounded corner: R2-2.5mm

8. Impact knife thickness: 16mm

9. Angle accuracy: ±0.1°

11. Sample size: 10×10×55mm

12. Dimensions: 2300 mm×600 mm×1400 mm

13. Net weight of the test machine: 550Kg

14. Power supply: AC three-phase 380V±10% 50HZ 5A

15. Environmental conditions: There is no corrosive medium, no vibration, and no strong electromagnetic field in the surrounding environment.

5. Main equipment configuration:

1. One 500 Joule host;

2. One pendulum 250J and one

3. One motor (installed on the host);

4. Take a set of pendulum transmission devices (installed on the main machine);

5. One set of insurance institutions (installed on the host);

6. A set of safety protection devices;

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

Recommended informationNEWS

- [2022-08-04]How to install a clamp to save effort

- [2022-08-04]What are the causes of oil leakage in the universal pressure test machine?

- [2022-08-04]Tension machine

- [2022-07-29]Staff must conduct necessary inspections on the different structures and parts of the fatigue testing machine

- [2022-07-29]In practical applications, friction between parts is inevitable.

- [2022-07-29]Methods to avoid positioning errors of electronic universal test machines

- [2022-07-29]What errors are prone to occur when using the fatigue test machine

- [2022-07-29]Performance characteristics of electronic universal testing machine and preparations before operation

- [2022-07-20]What are the safety and service life of the woven bag tensile tester?

- [2022-07-20]Several categories of tension machine sensors

- [2022-07-20]Calibration of universal testing machine sensor

- [2022-07-20]Introduction to technical problems of material tensile testing machine

- [2022-07-15]Handling of displacement system failure of tensile test machine

- [2022-07-15]Low temperature impact tester

- [2022-07-15]How to choose a horizontal tensile tester and what to note during experiments

- [2022-07-13]Tips for using universal testing machine

- [2022-07-13]About how to choose a high-precision material testing machine

- [2022-07-08]Impact sample notch hydraulic pulling bed (US standard)