News

Usage skills and maintenance of metal tensioning machines

Release time:2019-07-12 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

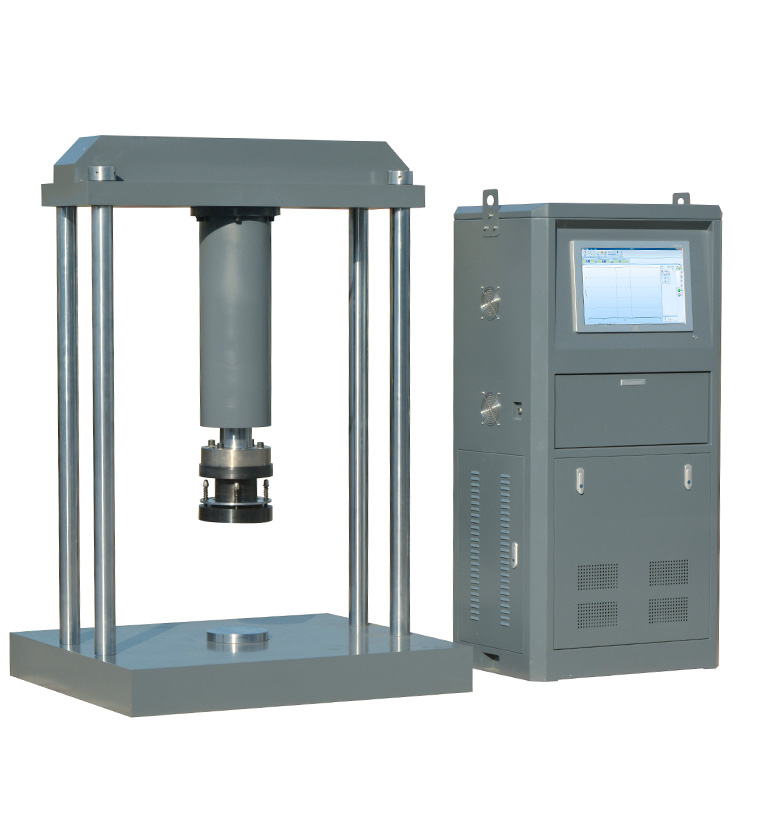

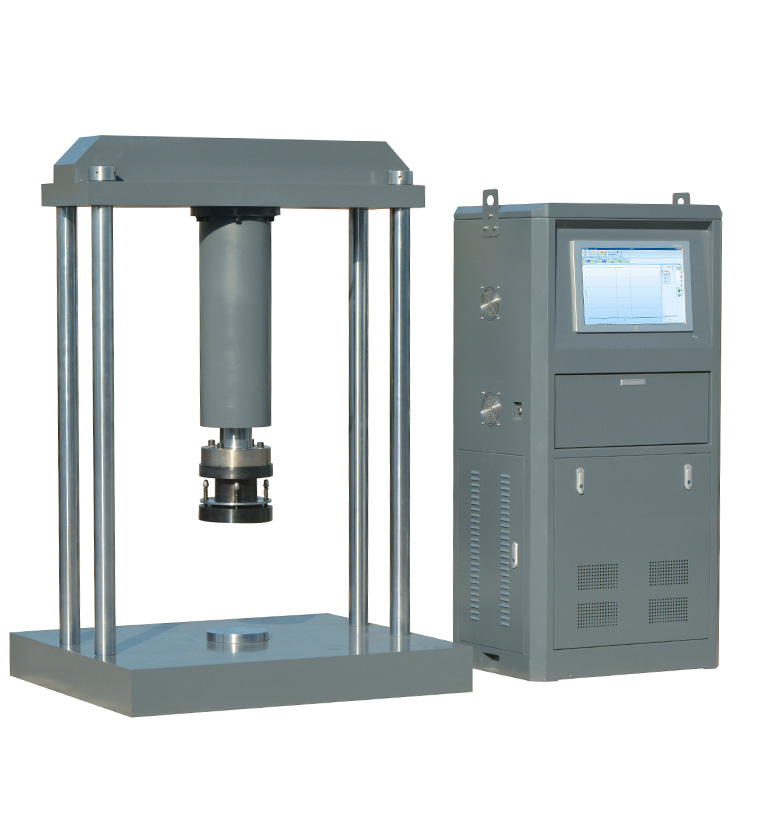

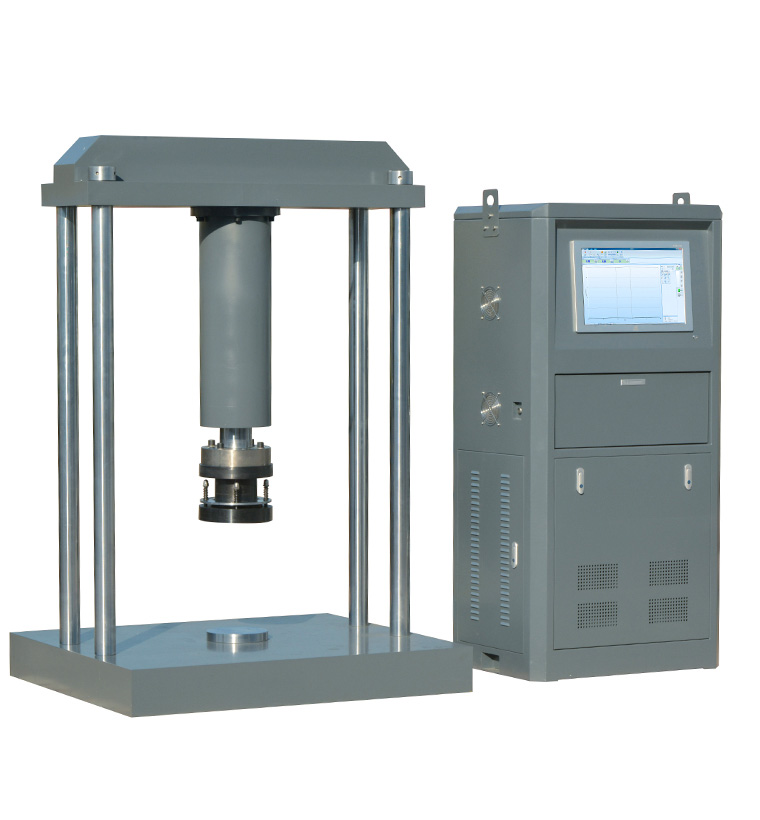

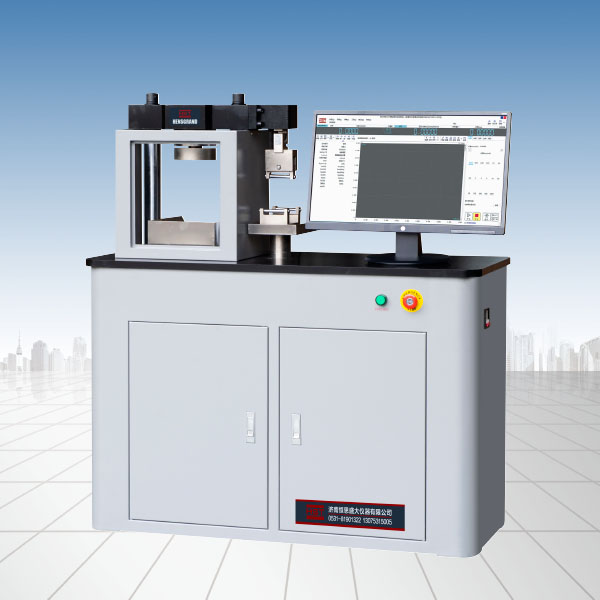

The metal tensioner can test the tension, compression, bending, tearing, 90° peeling, 180° peeling, shearing, adhesive force, pulling, pulling, pulling, 180° peeling, shearing, adhesion, pulling, pulling, elongation, etc., castings, steel plates, steel strips, non-ferrous metals, automotive parts, alloy materials and other non-metallic materials and metal materials.

Metal tensile machines are suitable for various physical tests and tests. Many non-professionals may not know how to use this tensile machine. Next, we will introduce to you the precautions for using this instrument. I hope this introduction can help you improve your usage efficiency.

Most people will first read the instruction manual after purchasing the device, because for professionals, the contents on the instruction manual of the instrument can give them a preliminary understanding of how to use the instrument. Therefore, before using the metal tensioner, we recommend that you carefully read the equipment instruction manual and have a certain understanding of the equipment, so as to help you become more handy in the later use. Below, I will introduce the usage techniques and maintenance of metal tension machines.

1. Tips for using metal tensioning machine:

First, it is its application object. For some special materials, I hope everyone will not test them blindly. We need to know whether this material is suitable for testing by metal tensioning machines, so as not to cause damage to the equipment, affect the test results and reduce working efficiency.

Secondly, we want to introduce the installation skills of metal tensioning machines. The test instruments and equipment still require relatively high data accuracy. If we conduct tests on uneven grounds or do not install every part of the equipment correctly, it may cause test errors and affect the test results. Therefore, everyone must pay more attention to installation.

In addition, we have to mention its considerations in the use environment. Metal tension machines also have certain requirements for the use environment. If there are a lot of stains or dust in the air, it is extremely easy to adhere to the equipment parts. In the long run, it will affect the operation of the equipment and may cause damage to the equipment in serious cases. Therefore, it is recommended that you choose to use the equipment in a clean, dry environment and no corrosive gases.

2. Maintenance and maintenance methods of metal tensioning machines:

1. Check the screws in the jaw area regularly. If they are found to be loose, tighten them in time;

2. The sliding surfaces in which the steel plate inlay and the lining plate and the dovetail groove surface on the lining plate should be kept clean, and a thin layer of molybdenum disulfide grease should be applied regularly;

3. Check the transmission status of the sprocket regularly. If you find loose, please re-tension the tensioner.

Maintenance of metal tension engine oil source:

1. Regularly check whether there is any oil leakage at the main engine and oil source. If there is oil leakage, the sealing ring or combination gasket should be replaced in time;

2. Regularly replace the oil suction filter and filter element according to the use of the machine and the service life of the oil, and replace the hydraulic oil;

3. When not doing tests for a long time, be careful to turn off the mains power supply. If the machine is in standby state, the switch should be turned to the "load" setting, because if the switch is turned to the "quick reversal" setting, the solenoid reversing valve is always in the power-on state, which will affect the service life of the device.

Maintenance of metal tensioner control system:

1. Regularly check whether the connection wire on the rear panel of the controller is in good contact. If it is loose, it should be tightened in time;

2. If you do not use the machine for a long time after the test, turn off the controller and computer;

3. The interfaces on the controller are one-to-one, and plugging in the wrong interface may cause damage to the device;

4. The interface on the plug-in and unplug the controller must be powered off.

The above is our related introduction to the use skills and maintenance of metal tension machines. Through our introduction, I hope it will be helpful to everyone in the later use of equipment and effectively improve work efficiency. Friendly reminder: If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation!

The four major values and three major functions of the strategy centerRecommended productsPRODUCTS