News

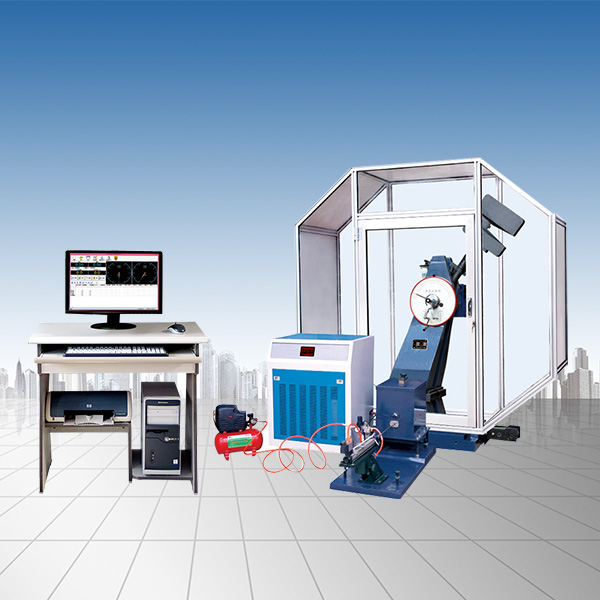

What installation preparations and commissioning work should be done for the film tensile testing machine?

Release time:2019-07-16 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

What installation preparation and debugging work should be done for the film tensile testing machine? Many users will have various problems after purchasing the film tensile testing machine because they have not done the pre-installation preparations. First of all, we need to understand that this is not the reason for the machine itself. A large possibility is that the preparation work is not done well, so it is very necessary for users to understand what preparations should be done and how to debug the film tensile testing machine before installation. Here, the editor will give you an explanation on the installation preparation and debugging work of the film tensile test machine:

1. Preparation work before installation of film tensile testing machine:

1. A clean, dry, vibration-free room temperature can be controlled in a room temperature;

2. Room with enough space;

3. Dig a hole at the installation location;

4. Apply horizontal horizon to the plane of concrete foundations;

5. Connect to a three-phase and four-wire power supply, and the power supply should be equipped with an air switch and a leakage protection device.

2. Connection of hydraulic system of film tensile testing machine:

1. Remove all kinds of bundlings and clean the inside of the oil pipe;

2. Check whether the gasket at the joint is complete;

3. Use a suitable wrench to connect the oil pipe;

4. Remove the residual oil in the fuel tank and remove the residue in the fuel tank.

5. Open the iron door of the hydraulic control box;

6. When refueling, be sure to pay close attention to the oil level.

3. Debugging of film tensile testing machine:

1. Turn off the oil pump motor, unscrew the wire block on the oil pump, and discharge the air in the pump;

2. Turn on the oil pump and lift the piston repeatedly to drain the air in the oil cylinder and oil pipe;

3. Pull the cold bend support equally apart to both sides;

4. Install the spherical lowering plate on the platen;

5. Start the oil pump, close the oil return valve, open the oil supply valve, so that the platen rises, and slowly increase the pressure;

6. Check whether there is any oil leakage at each oil pipe joint;

7. If there is oil leakage, tighten the joints at the oil after unloading the force.

The installation preparation of the film tensile testing machine is the most important step in the early work and must not be ignored! As long as the installation preparation is done, the subsequent debugging and use will be smoother. The above is what installation preparation and debugging work should be done for the film tensile testing machine we introduced to you, hoping that it can help you.

Strategy Center Business FAQRecommended productsPRODUCTS