News

Precautions and maintenance of hot and cold impact testing machine

Release time:2019-08-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The hot and cold impact tester is a necessary testing equipment in the metal, plastic, rubber, electronics and other materials industry. It is used to test material structures or composite materials. It can be tolerated in a continuous environment of extremely high temperatures and extremely low temperatures in a short time to detect chemical changes or physical damage caused by thermal expansion and contraction of the sample in the shortest time. What the editor wants to share with you is the precautions and maintenance of the hot and cold impact test machine, so that everyone can further understand the hot and cold impact test machine.

1. Precautions for using hot and cold impact testing machine

1. Precautions for using hot and cold impact testing machine

1. During the test operation, please do not open the box door unless it is absolutely necessary, otherwise the following adverse consequences may be caused. It is very dangerous to rush out of the box with high temperature hot air. The inside of the box door is still maintained at high temperature, causing scalding. High temperature air may trigger a fire alarm and cause malfunctions.

2. Please note that the machine must be safely grounded to avoid electrostatic induction.

3. Avoid turning off the cold and cold impact test machine within three minutes and then turning on the refrigeration unit.

4. If heating samples are placed in the box, please use an external power supply to control the sample power supply, and do not use the power supply directly.

5. The hot and cold impact test machine has no fuse switch (circuit circuit breaker) or temperature overtemperature protector, providing safety protection for this machine test items and operators, so please check regularly.

6. Testing explosive, flammable and highly corrosive substances is absolutely prohibited.

7. Please read the instructions in detail before operating the hot and cold impact test machine.

2. Maintenance of hot and cold impact testing machine

1. The refrigeration system of the hot and cold impact test machine is the core of the test machine. All copper pipes must be inspected once a year for snow leakage. Each horn joint and welding interface. If there is any oil stain leak, please deal with it directly or inform the original manufacturer.

2. When opening and closing the door or taking the test object from the furnace, the items must not be allowed to come into contact with the glue edge on the door to prevent the glue edge from being damaged and shortened.

3. The ground around the fuselage and at the bottom should be kept clean at all times to avoid accidents and performance reduction due to large amounts of dust sucking into the unit.

4. The radiator (condenser) of the refrigeration unit of the hot and cold impact tester should be maintained regularly and kept clean. The dust-sticky condenser will cause the compressor's high-pressure switch to jump off and cause a false alarm. The condenser of the hot and cold impact test chamber should be maintained regularly and monthly. Use a vacuum cleaner to suck off the dust attached to the condenser heat dissipation mesh. After turning on the machine, use a hard brush or use a high-pressure air nozzle to blow the dust.

5. The high current contact of the distribution board is cleaned and inspected at least once a year. The loose contact will cause the entire equipment to be in a dangerous working state. At the very least, the components are burned out, and at worst, fire, alarm, or personal injury is very dangerous. When cleaning, use a vacuum cleaner to suck out the indoor dust.

6. Please do not debug the two overtemperature protectors in the distribution box casually. They have been adjusted when leaving the factory. This protection switch is used to protect the air incineration and water shortage alarm of heating pipes and humidification pipes. The set point of the hot and cold impact test chamber = temperature set point + 20℃ ~ 30℃

7. Inspection and maintenance of the waterway of the hot and cold impact tester. The water pipes of the waterway are devices that are prone to blockage and leaks. Please be sure to check regularly for any leakage and water blockage. If there is any, please eliminate them in time or notify the company.

8. When the test product is picked up after the time of the test product has reached, the product must be removed and the staff must wear dry, electrically resistant and temperature-resistant gloves to pick up and put the product.

9. The hot and cold impact test machine should remove internal impurities (items) before operation.

10. Clean the electric room at least once a year. Please use a vacuum cleaner to suck out the indoor dust. Clean the outside of the box of the hot and cold impact test chamber once or more a year. Wipe it with soapy water during cleaning.

After understanding the precautions and maintenance of the hot and cold impact test machine, the operator must use it in accordance with the procedures and specifications of the instructions when using the press. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. Friendly reminder: If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

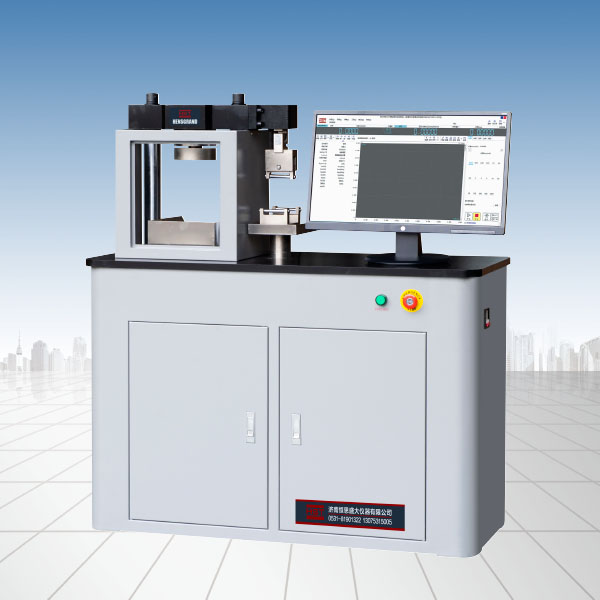

Introduction to Certification Service Provider-UniDeskRecommended productsPRODUCTS