News

Performance characteristics and maintenance of infrared carbon sulfur instruments

Release time:2019-08-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

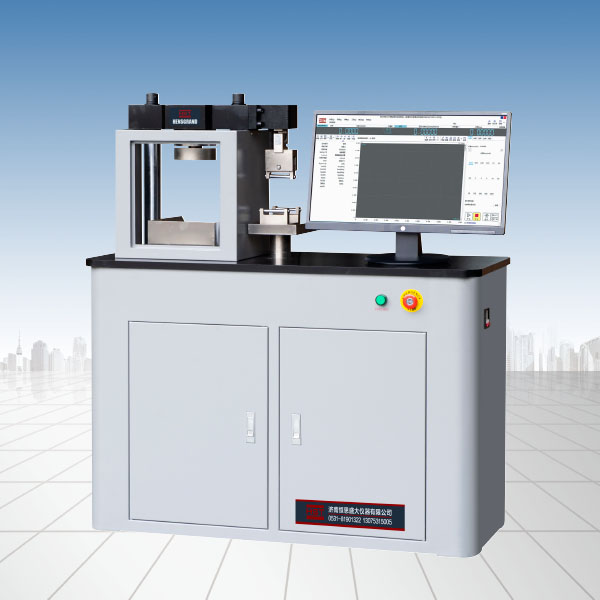

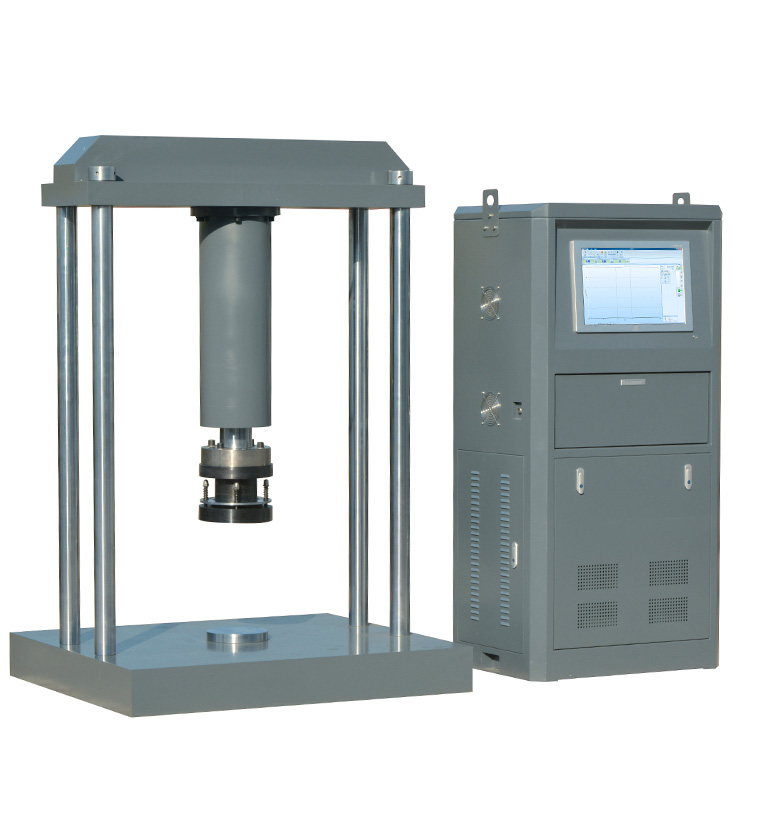

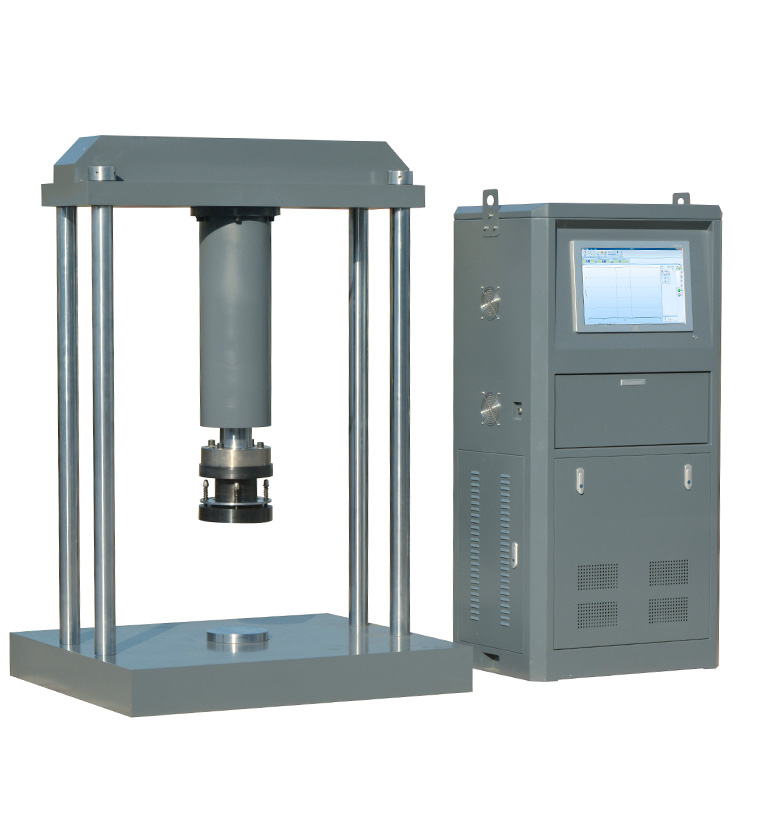

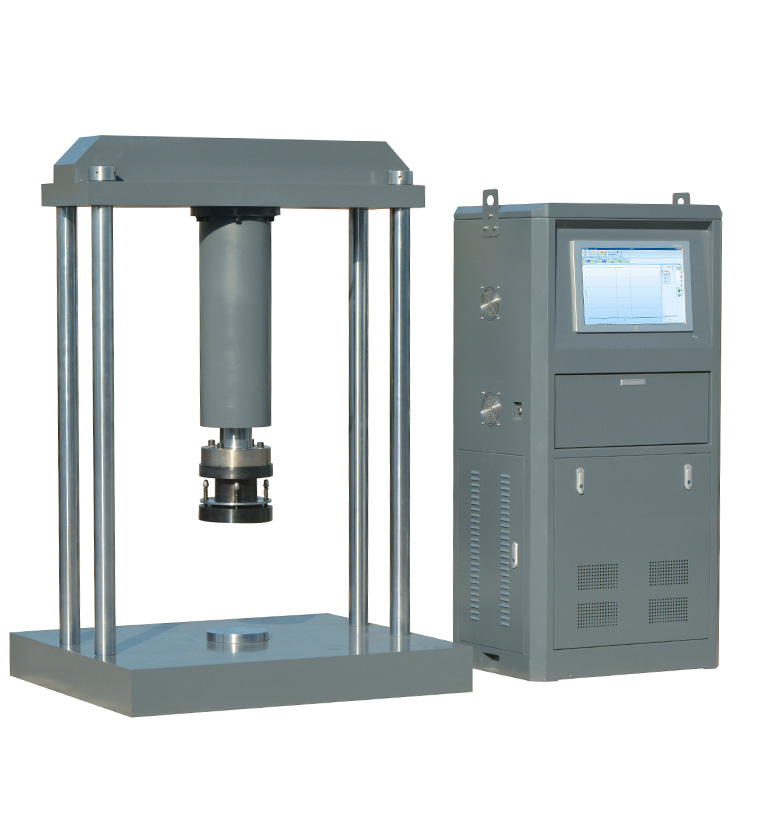

Infrared carbon sulfur analyzers are mainly used to analyze the carbon and sulfur content in ferrous metals, non-ferrous metals, rare earth metals, inorganic substances, ores, ceramics and other substances in metallurgy, machinery, commodity inspection, scientific research, chemical industry and other industries. The infrared carbon and sulfur analyzer of the analytical instrument uses a high-frequency induction heating furnace to burn samples, and the infrared absorption method tests the mass fraction of carbon and sulfur in the samples. What our company's technicians want to introduce to you is the performance characteristics and maintenance of infrared carbon sulfur instruments.

1. Performance characteristics of infrared carbon sulfur meter

1. Adopt infrared detectors with low noise, high sensitivity and high stability.

2. The modular design of the whole machine improves the reliability of the instrument.

3. The electronic balance is automatically online and can be weighed in quantities.

4.WINDOWS full Chinese operation interface is easy to operate and easy to master.

5. The infrared carbon sulfur instrument software has complete functions and provides more than 40 functions including file assistance, system monitoring, channel selection, data statistics, result correction, breakpoint modification, and system diagnosis.

6. Dynamically display various data and carbon and sulfur release curves during the analysis process.

7. The measurement has a wide linear range and is scalable.

8. The high-frequency circuit design of infrared carbon sulfur meter is reasonable, the power of the high-frequency furnace is adjustable, and it is suitable for sample analysis requirements of different materials.

9. The furnace head automatic cleaning device can reduce the impact of dust on the analysis results.

10. The furnace head heating device makes the conversion of sulfur consistent, improving the stability of sulfur determination.

2. Maintenance of infrared carbon sulfur analyzer

1. Dust in the combustion chamber of infrared carbon sulfur analyzer:

During the combustion of the sample, Fe2O3 and WO3 dust are generated and accumulated over the metal filter and quartz tube. If too much dust accumulates, it will have an adverse effect on oxygen flow, high-frequency induction heating, etc., making the carbon sulfur analysis result low and unstable. Therefore, it needs to be cleaned during the sample analysis or after the analysis is completed. During the analysis process, dust removal is required once after 10 consecutive samples are analyzed.

Dust removal method:

Open the instrument panel and press the dust removal button. The instrument will automatically clean the dust and collect the dust in the dust accumulation box.

After the sample is burned in a high-frequency furnace, the mixed gas (CO2, SO2, O2) is entered into the analyzer for inspection through the 3# purification tube. In the 3# purification tube, magnesium perchlorate is installed on the upper part to absorb the water that may be generated after burning the crucible and the sample to eliminate the impact on sulfur analysis. The lower part is filled with degreased cotton to secondary purification of possible residual dust in the mixed gas to ensure that the detection system is not contaminated by dust.

2. Dust inside the high-frequency combustion furnace of infrared carbon sulfur analyzer:

After a long period of use of the instrument, a small amount of dust will accumulate inside the instrument, and most of the dust is metal dust, which is conductive. Because there is a high voltage and high frequency environment in the high-frequency induction furnace, it is easy to conduct electricity in the device after too much dust, resulting in circuit short circuits, ignition and other phenomena, which will burn the entire equipment in severe cases. Therefore, the dust inside the instrument should be cleaned regularly according to the placement environment and the frequency of sample preparation, and is generally dust removal every 6-8 months.

Dust removal method:

Open the high-frequency combustion furnace panel, brush the high-frequency components and high-frequency chamber with a brush, remove most of the dust, and then blow the oxygen tube towards the instrument to blow away the remaining dust. Cover the instrument panel again. (Note: During the entire operation, the instrument power should be disconnected and the power cord should be unplugged to avoid accidents).

3. Replacement of quartz tube of infrared carbon sulfur analyzer

Quartz pipes are consumables and need to be replaced or cleaned after damage or long-term use.

(1) Disassembly of quartz tube

① Remove the shielding mask on the upper left side of the high-frequency furnace.

②Down the cylinder, open the furnace head, and remove the crucible bracket and crucible seat.

③ Loosen counterclockwise (see from bottom to top) The furnace tube pressing cap above the quartz tube is about half a circle, so that the pressure cap and seal "O" ring are loose. Hold the quartz tube in your hand and take out the quartz tube from below the furnace tail.

(2) Cleaning of quartz tube

(3) Installation of quartz tube: follow the disassembly steps to reverse.

Before using any test machine, you must fully understand the performance and maintenance of the product so that you can better achieve human-machine running-in during operation. This improves production efficiency. The above are the performance characteristics and maintenance of infrared carbon sulfur instruments, and I hope they can help you. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

Data Banking Service Provider CertificationRecommended productsPRODUCTS