News

Functions and operation steps of electronic universal testing machine

Release time:2019-09-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

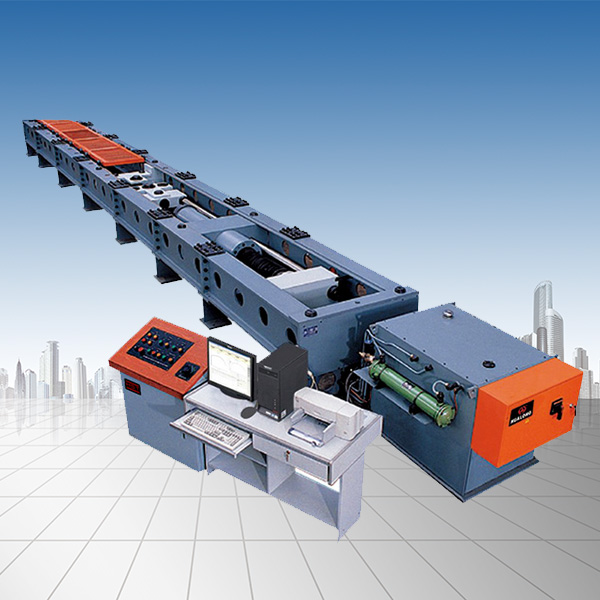

The electronic universal testing machine is a new generation of dual-space microcomputer controlled electronic universal testing machine designed specifically for universities and research institutes. The design of the test machine host and auxiliary equipment draws on advanced technology from Japan's Shimadzu, with beautiful appearance, convenient operation, and stable and reliable performance. Today we will introduce to you the functions and operating steps of the electronic universal testing machine. Let’s take a look.

1. Functions of electronic universal testing machine

1. The electronic universal test machine adopts a Taiwan AC frequency converter motor, with stable and reliable performance, and has protection devices such as overcurrent, overvoltage, overspeed, and overload. The speed regulation ratio can reach 1:5000.

2. The electrical control circuit refers to international standards and complies with the national electrical standards of test machines. It has strong anti-interference ability, ensuring the stability of the controller and the accuracy of experimental data.

3. Condition storage: Test control data and sample conditions can be made into modules, which facilitates batch testing.

4. Automatic speed change: The speed of moving the beam during the test can be automatically changed according to the preset procedure or can be changed manually.

5. Automatic calibration: The system can automatically realize calibration of display accuracy.

6. Process implementation: The test process, measurement, display and analysis are all completed by the microcomputer.

7. Batch test: For samples with the same parameters, they can be completed in sequence after setting them once.

8. Test software: Chinese WINDOWS interface, menu prompts, and mouse operation.

2. Operation steps of electronic universal testing machine

1. Turn the main switch on the power supply.

2. According to the sample, select the measurement range, hang or remove the swing thallium on the swing rod and adjust the buffer valve handle to align the standard line.

3. Install the corresponding chuck into the upper and lower jaw seats according to the shape and size of the sample.

4. The electronic universal testing machine rolls the recording paper (grammed paper) on the drum of the depictor. This item is only carried out when necessary.

5. Turn on the oil pump motor, unscrew the oil feed valve to make the test stand raise paper 10 mm, and then close the oil valve. If the test stand is already in the raised position, there is no need to turn on the oil pump first, just close the oil feed valve.

6. Clip one end of the sample into the upper jaw.

7. Turn on the oil pump adjustment point to the zero point of the accuracy dial.

8. Turn on the lower jaw motor, lift and lower the lower jaw to an appropriate height, clamp the other end of the sample into the lower jaw, and be careful to make the sample perpendicular.

9. The electronic universal testing machine lowers the drawing pen on the push rod and enters the drawing ready state (it is only done when the drawing is required).

10. According to the loading speed required by the test, slowly unscrew the oil feeding valve for loading test.

11. After the sample is broken, close the oil valve and stop the oil pump motor.

To sum up, this is a detailed introduction to the functions and operating steps of the electronic universal testing machine. Have you understood it? I hope this article can help you. Friendly reminder: If you have any unclear areas, please call us for consultation. Jinan Hengsi Shanda Testing Equipment Co., Ltd. is a modern high-tech company focusing on research and development, design, production and sales of test equipment. A variety of machines for you to choose from!

Recommended productsPRODUCTS