Current location:front page >> Product Center >> Impact testing machine series >> Impact testing machine

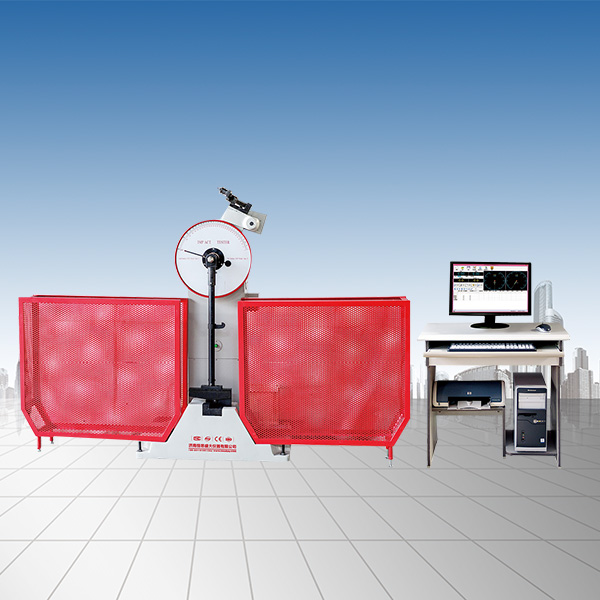

JBW-300B microcomputer screen display impact tester

JBW-300B microcomputer screen display impact tester

Product Classification: Impact testing machine

Product Overview:This series of test machines calculates the absorption work of the impact sample by measuring the difference between the front position energy of the pendulum impact and the remaining position energy after the impact; the test machine is semi-automatically controlled, and the swing, hanging, impact, and release are all electrically controlled. It can use the remaining energy after the punching sam

Main uses

The JBW series impact testing machine is used to test the performance of metal materials to resist impact under dynamic loads. It is an essential testing instrument for metallurgy, mechanical manufacturing and other units. It is also an indispensable testing instrument for scientific research institutions to conduct new materials research. This series of models is also a common impact testing machine currently used on the market.

Technical Features:

♦This machine adopts PC microcomputer control, electric swing, impact, microcomputer measurement, calculation, screen display results and printable, etc., with high working efficiency and high testing accuracy. After impacting the sample, the remaining energy can be used to automatically swing, and prepare for the next test, which is easy to operate and high working efficiency. The computer can calculate and digitally display the impact absorption work, impact toughness, pendulum angle and test average value of the material, and can print the current test data and the average value of the test.

♦The main unit of the test machine is a single-supported column structure, cantilever hanging pendulum, and a pendulum pituitary U-shaped;

♦The impact knife is installed and fixed by screws, making it easy to replace;

♦Simplified support beam type support for specimen;

♦The host is equipped with a safety protection pin and is equipped with a safety protection net;

♦The test machine is semi-automatically controlled, and the swing, hanging, impact and release are electrically controlled. It can use the remaining energy after the sample is broken to automatically swing and prepare for the next experiment. It is especially suitable for laboratories that perform continuous impact tests and metallurgy, mechanical manufacturing and other departments that perform large amounts of impact tests; the test machine complies with the requirements of GB/T229-2007 "Metal Shabby Notch Impact Test Methods" for impact tests on metal materials.

Technical parameters

model | JBW-300B | JBW-500B |

Display method | Microcomputer screen display | |

Impact energy | 150/300J | 250/500J |

Distance from center of the swing axis to impact point | 750mm | 800mm |

Shock speed | 5.2m/s | 5.4m/s |

Pendulum pre-scaling angle | 150° | |

Sample support span | 40+0.2mm | |

Claw rounded corners | R1-1.5mm | |

Impact blade rounded corner | R2-2.5mm, R8±0.05mm | |

Sample size | 10 (7.5, 5, 2.5)mm×10mm×55mm | |

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

- Previous article:WDW series digital explicit cable sheath tensile testing machine

- Next article:Rubber tensile testing machine

Recommended informationNEWS

- [2025-05-20]Gate terminal tensile testing machine

- [2025-05-20]How to install and operate the tensile tester

- [2025-04-09]A list of test standards for rubber and its products

- [2025-04-09]Explanation of 9 test items of wire tension testing machine

- [2025-03-25]Common obstacles and methods for e-tension testing machines

- [2025-03-25]What should be paid attention to when operating and testing the impact test machine?

- [2025-03-20]Find different plastic test

- [2025-03-20]Characteristics and types of electro-hydraulic servo systems

- [2025-03-14]Process Standards of Tensile Testing Machine

- [2025-03-14]Test machine repair, test machine failure

- [2023-11-28]Hengsi Electronic Universal Testing Machine Hydraulic Universal Testing Machine Loading and Delivering

- [2023-11-27]Functions of electronic universal testing machine

- [2023-11-14]Breaking tension of wire rope

- [2023-11-03]Preparation of tensile test specimens of glass fiber woven fabric

- [2023-10-16]Wire and cable tension testing machine

- [2023-09-20]From September 19 to 23, 2023, Shanghai New Materials Industry Exhibition, welcome to visit and exchange at our booth!

- [2023-09-01]The yield point, tensile strength, material yield strength, carbon steel knowledge of metal steel

- [2023-08-25]Types of electronic universal testing machine fixtures