News

Component functions of pressure testing machine and quarterly maintenance

Release time:2020-01-08 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

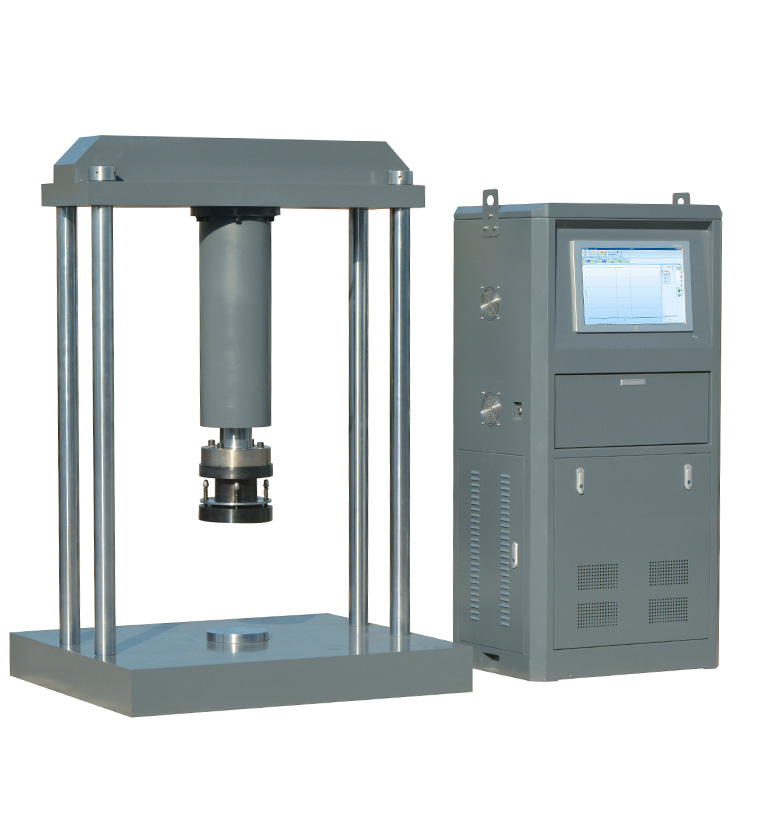

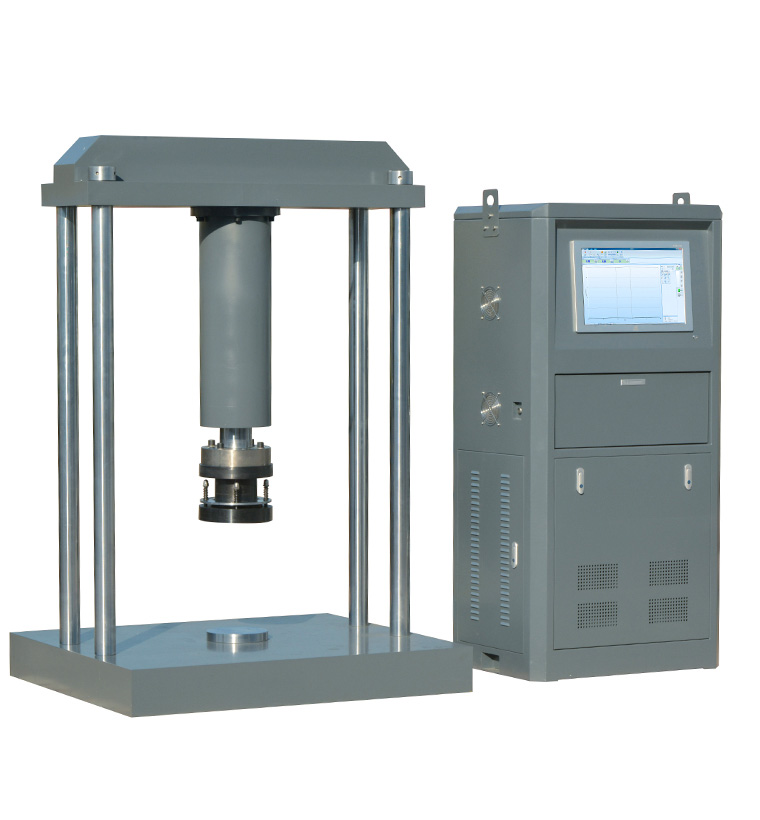

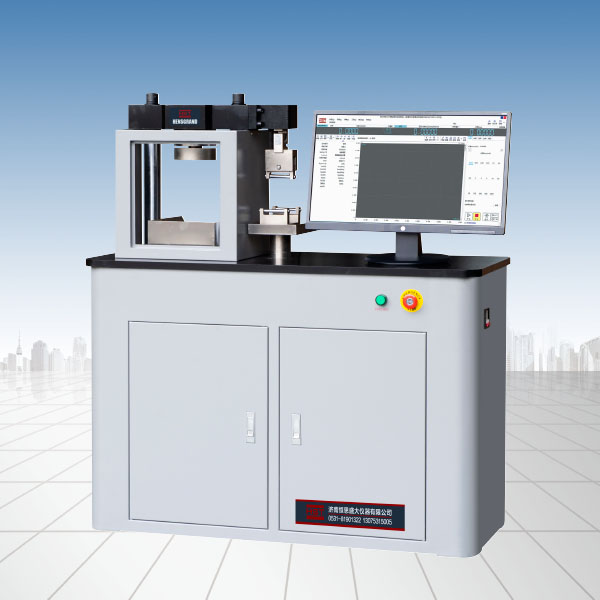

Pressure testing machine, also known as electronic pressure testing machine, is mainly suitable for various physical and mechanical performance testing of rubber, plastic sheets, pipes, special profiles, plastic films, wires and cables, waterproof rolls, metal wires, cartons and other materials. The pressure tester is a device that can test the performance of objects in various aspects. This time, I will introduce the components of the pressure tester and the quarterly maintenance.

1. Component functions of pressure test machine

1. High quality of parts

All parts of the pressure test machine are made of parts produced by internationally renowned manufacturers. The parts are of high quality and can effectively ensure the operating efficiency of the test machine. Moreover, no welding was taken for parts in the equipment, making the overall equipment more beautiful. In addition, the welding-free treatment makes the disassembly of the test machine more abundant, has a high safety factor, and has a large extension of the service life.

2. Supercharge pump

The pressure tester is equipped with a booster pump component equipment, which can output any pressure value according to actual needs. The design of the booster pump improves the flexibility of the tester's operation, because the output pressure can be adjusted in real time, which can better meet the needs of various industries.

The booster pump is also equipped with a recording instrument, which can record the pressure generated by the equipment during operation in real time. In particular, the instant blasting capability of the booster pump during operation can be recorded in real time and accurately, making the measured data more complete and meeting the needs of operators.

3. Reasonable design

The pressure tester was designed safely and reasonably before manufacturing, and in addition to this, it strives to pursue the simplicity and practicality of the tester structure. Because of the reasonable structural design, the area of the test machine is effectively reduced and more space can be freed up for other equipment.

4. Select the control mode by yourself

The pressure tester has a self-test function and can set relevant parameters according to the measurement requirements of the object to be measured, so that the tester can measure the relevant objects by itself. However, due to various factors, the automatic measurement mode cannot be used. At this time, you can switch to the manual measurement mode and manually measure the relevant objects to ensure the normal measurement work.

2. Quarterly maintenance of pressure testing machines

1. As a high-tech testing equipment, we can find that there are different structures in the pressure testing machine. During the quarterly maintenance process, relevant staff need to conduct corresponding inspections on each structure of the equipment to ensure that sufficient lubrication measures are taken.

2. For the main part of the test machine, thorough and effective inspection is also required to ensure that no abnormal noise or other problems are generated during use. In addition, there are different buttons and control keys in the pressure test machine, which must be checked in the quarterly maintenance plan to see if they can be controlled flexibly.

3. At this stage, the test machine devices launched by different manufacturers are also equipped with corresponding protection devices and equipment control device systems. Everyone needs to check these two key points to ensure that the overall performance of the equipment is better protected.

4. Carry out cleaning and maintenance in relatively blind spots, and check the relevant performance of the equipment to see if accurate tests can be made.

5. Are the cables and wires of the equipment already have aging or damaged problems? Once discovered, they must be replaced in time.

6. The pressure tester has many different fixing screws. Pay attention to whether the screw nuts in each part are loose, rust, etc. If you find any problems with any accessories of the tester, you need to replace them as soon as possible.

7. Ensure that the equipment circuit has a good grounding state and there are no missing or damaged components. If there are, the original manufacturer's components must be ordered for replacement to avoid distortion of the data that affects the later detection test.

After understanding the component functions of the pressure test machine and quarterly maintenance, operators must use it in accordance with the procedures and specifications of the instructions when using the pressure test machine. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

Recommended productsPRODUCTS