News

Various classification characteristics and standardized operation steps of drop test machine

Release time:2021-05-12 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The drop tester can conduct free drop tests on the surface, angle and edge of the packaging. It is equipped with a digital height display instrument and a decoder to track the product's drop height accurately, and the error with the preset drop height will not exceed 2%. What the editor wants to share with you is the various classification characteristics and standardized operation steps of the fall test machine.

1. Various classification characteristics of fall test machine

1. Zero drop test machine

Features: The zero-drop tension machine has a test piece bracket. During the test, the pallet moves downward at high speed and leaves the test piece. Before the test packaged goods fall to the bottom plate, the bracket is embedded flat on the bottom plate under the action of a high-efficiency shock absorber. In theory, the zero-drop tensioner can perform drop tests from the range of zero height to the maximum drop height. The drop height is digitally set through the test requirements, and the drop test is automatically performed according to the set height. There are different and same characteristics between drop tension machines. Therefore, when choosing a drop tension machine, you should know which drop tension machine your product is suitable for.

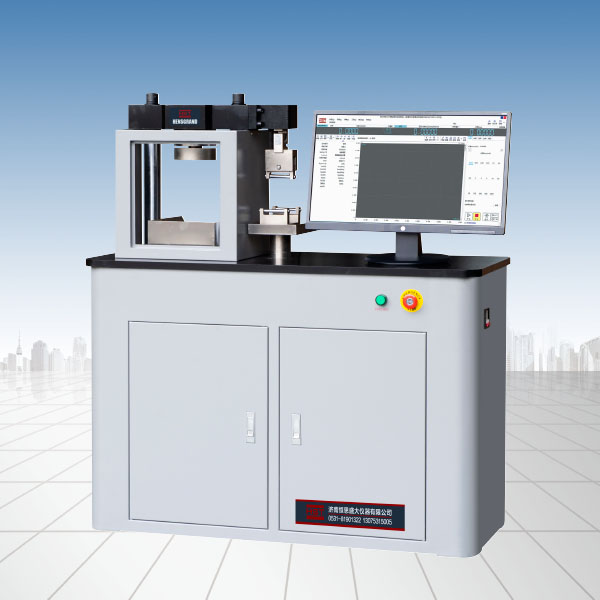

2. Single-arm drop test machine

Features: The single-wing drop tensioner places the product to be tested in a certain placement method: the surface, edge, and angle method make it fixed and display the height. You can set any height within the equipment test range as required by the user. After determining the height, release the solenoid valve and the test piece product will fall freely from the arm wing in an instant. Press the "Stop key" to drop the board to have an automatic re-set function.

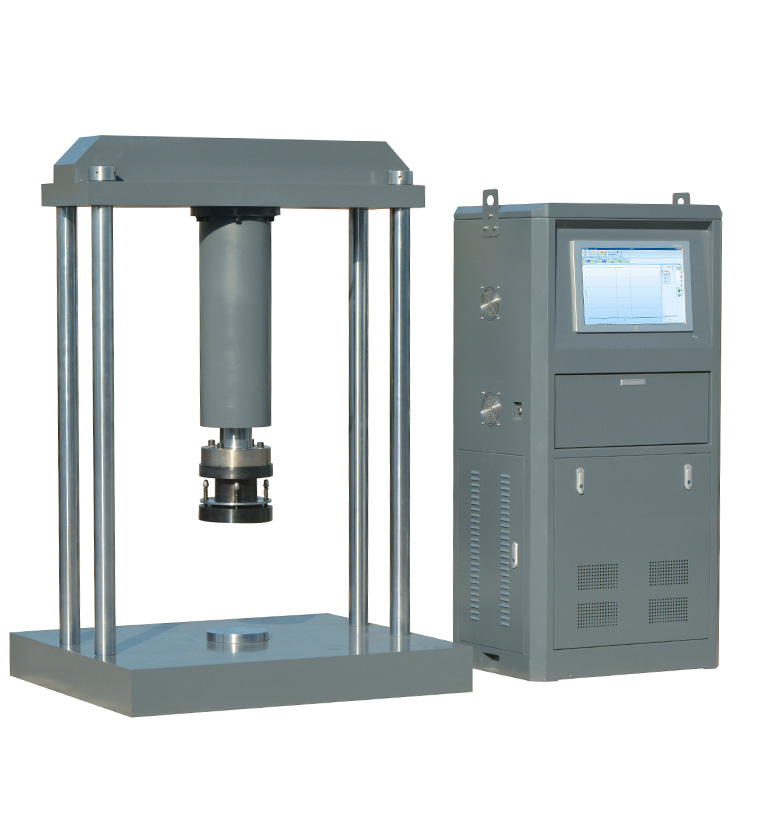

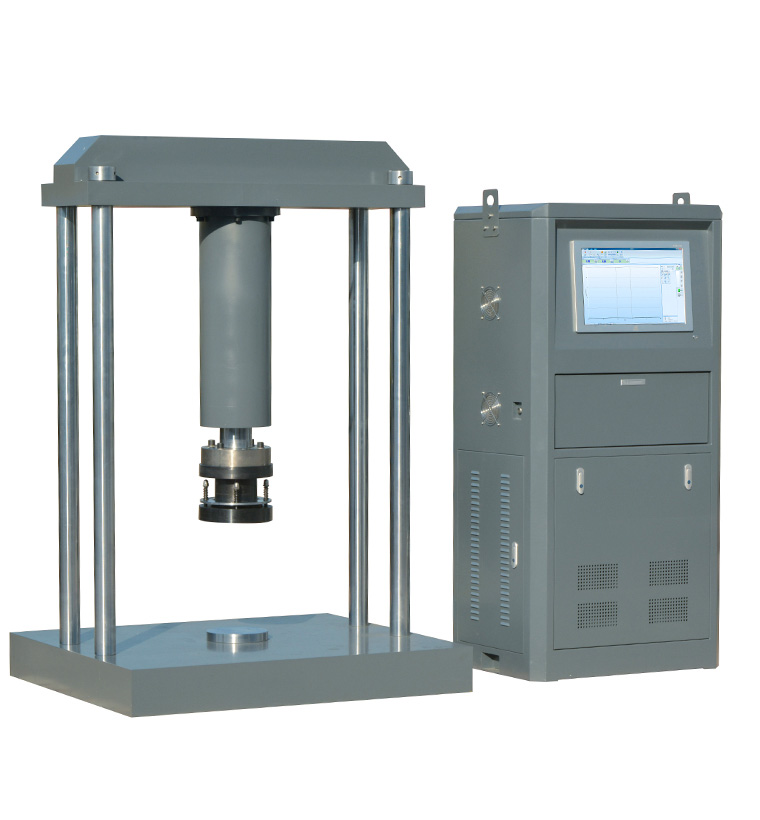

3. Two-arm drop test machine

Features: The double-arm drop tensioner can conduct free drop tests on the surface, angle and edge of the packaging. It is equipped with a digital height display and a decoder for height tracking, so that the product drop height can be accurately given. The double-arm drop tensioner adopts a single-arm double-column structure, with electric reset, electronically controlled drop and electric lifting devices, which are easy to use. With a single arm setting, the product can be placed conveniently, and the angle error between the impact surface of the drop angle and the floor plan is less than or equal to 5 degrees.

2. Standard operation steps of drop test machine

1. Wiring: The included power supply must be connected to the three-phase power supply and also grounded. Then connect the control box to the link wire randomly provided by the drop test machine, and try to run the rising and falling command. If you are fainting, you press the rise button but run downward or press the fall button but rise, you just need to change the phase number at the power supply.

2. Place the sample to be tested on the work surface and fix it with a fixing rod;

3. Press the drop button to instantly leave the measured sample, so that the measured sample can fall freely;

4. Press the rising key to lift the sample to be tested to the set height.

5. Press the reset key to restore work status of the workbench

6. Adjust the drop height: Turn on the mains power and set the height required for the test.

After understanding the various classification characteristics and standardized operating steps of the fall test machine, the operator must use it in accordance with the procedures and specifications of the instructions when using the test machine. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have more relevant knowledge you want to know, please contact our customer service staff through the web page, and we will answer them one by one!

Recommended productsPRODUCTS