News

What should be noted when using the repetitive bending test machine for steel bars?

Release time:2022-09-28 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

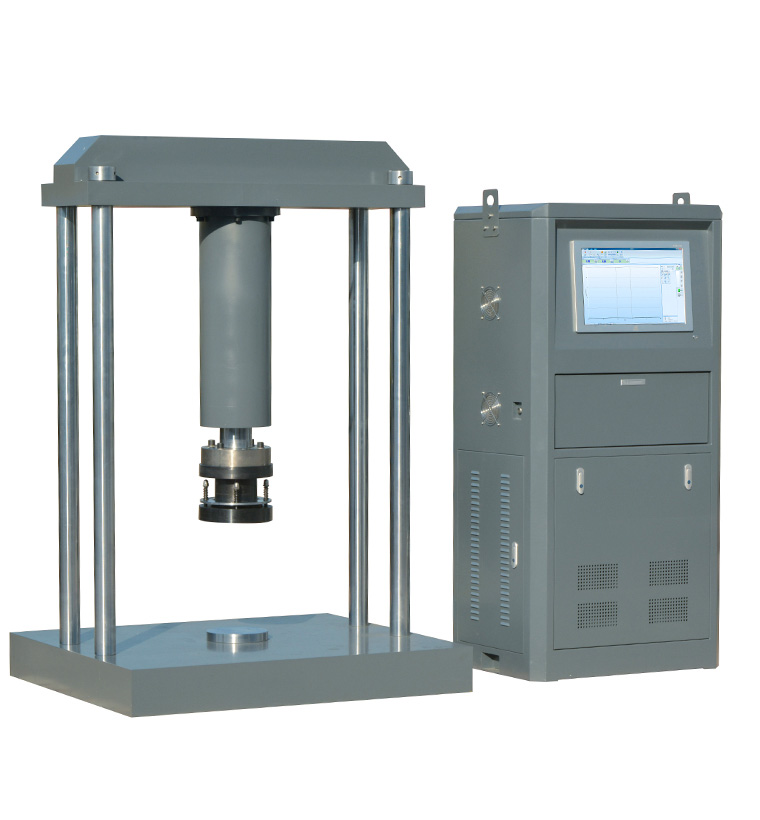

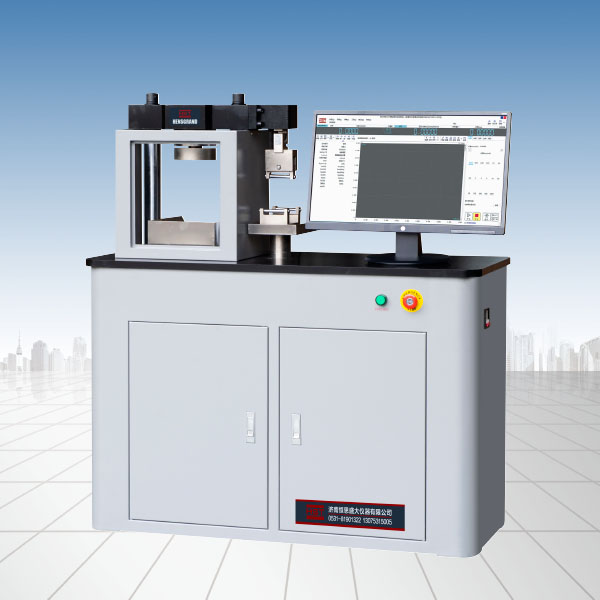

Rebar repetitive bending test machines are widely used in steel, construction industry, steel bars, prestressed steel wires, wire ropes, wire cables, copper and copper alloy contact wires, conductors, etc. So what should we pay attention to when using the repetitive bending test machine? What is the working environment of the repetitive bending test machine? Let’s learn about it with the editor below!

1. Things to note when using the repetitive bending test machine:

1. Check whether the mechanical performance is good, whether the workbench and bending machine workbench are level; and prepare various mandrel tool blocks.

2. Install the mandrel, forming shaft, iron guard or variable guard according to the diameter of the processed steel bar and the requirements of the bending machine. The diameter of the mandrel should be 2.5 times the diameter of the steel bar.

3. Check the spindle and plug for damage and cracks. The protective cover is securely fastened. Only after confirming that the empty machine is normal can the operation be carried out.

4. When the steel bar is repeatedly bending and testing machine is operated, insert one end of the steel bar to be bent into the fixed gap, and the other end is tightly attached to the machine body and press it tightly with your hands. Check whether the body is fixed and can only be started after installing it on the side that blocks the steel bars.

5. It is strictly forbidden to replace the mandrel, change the angle and adjust the speed during operation, and it is also strictly forbidden to refuel or unload oil.

6. When bending steel bars, it is strictly forbidden to process steel bar diameter, quantity and mechanical speed that exceed mechanical requirements.

7. When bending high hardness or low alloy steel rods, the mark of the large limit diameter must be changed according to the provisions of the mechanical nameplate and the corresponding core rod must be replaced.

8. It is strictly forbidden to stand within the working radius of the bent steel bars and the unfixed side of the fuselage. The curved semi-finished products should be stacked neatly and the hooks should not be upwards.

9. When reversing, you must park stably before proceeding.

10. After the operation is completed, clean the site, maintain the machine, and power outage lock box

2. Working environment of the repetitive bending test machine of steel bars:

1. Relative humidity is ≤80% within the room temperature range of 10℃~35℃;

2. On a solid foundation or workbench;

3. In an environment without vibration and corrosive media;

4. The fluctuation range of the power supply voltage shall not exceed ±10% of the rated voltage.

Recommended productsPRODUCTS