News

Basic knowledge and performance inspection of rebar

Release time:2022-10-14 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Currently, house construction and civil engineering in my country are mainly reinforced concrete structures, and rebar, as one of the main raw materials of this structure, will directly affect the quality of the project construction and be related to public safety and personal property safety. From highways, railways, bridges, culverts, tunnels, flood control, dams and other public facilities, to small buildings, foundations, beams, columns, walls, and plates of house buildings, rebars are indispensable structural materials. According to statistics, in recent years, my country's rebar production accounts for more than one-fifth of my country's total steel production. It is a product with a large amount of use and a very wide range of use. Therefore, in terms of the number of enterprises and product output, rebar plays an important role in my country's metallurgical industry and national economy.

1. What is rebar

Rebar is a ribbed steel bar. Also known as hot-rolled ribbed steel bars, they usually have two longitudinal ribs and transverse ribs evenly distributed along the length direction. The shapes of the horizontal ribs are spiral, herringbone, and crescent. The hot-rolled ribbed steel bar grades for reinforced concrete in my country are composed of HIRB and the minimum yield point value. H, R, and B are the first letters in English with three words Hotrolled, Ribbed, and Bars. According to the classification method of GB 1499.2 "Steel for Reinforced Concrete Part 2 Hot Rolled Ribbed Steel Bars", hot rolled ribbed bars are divided into six grades: HRB335, HRB400, HRB500, HRB335E, HRB400E, and HRB500E.

2. Classification of rebar

There are three commonly used classification methods for rebar:

1. Classify by geometric shape

Rebar is classified or typed according to the cross-sectional shape of the transverse ribs and the spacing of the ribs. For example, in the British Standard (BS4449), rebar is divided into type I and type II. This classification method mainly reflects the grip performance of rebar.

2. Classification by performance (level)

For example, in my country's current implementation standard GB1499.2, rebar is divided into three levels according to strength level (yield point/teny strength); in the Japanese Industrial Standard (JISG3112), rebar is divided into five types according to comprehensive performance; in the British Standard (BS4461), several levels of rebar performance tests are also specified.

3. Classification by use

According to the classification of use, rebar can be divided into ordinary steel bars for reinforced concrete and heat-treated steel bars for prestressed reinforced concrete.

3. Mechanical performance inspection of rebar

Rebar is mainly used for the skeleton of reinforced concrete building components, and is required to have certain process welding performance, mechanical strength and bending deformation performance during use. The raw material of rebar production is carbon structural steel or low alloy structural steel that has been calmly melted and treated. It mainly bears tensile stress in concrete. Due to the role of ribs, rebar has a greater bonding ability to concrete, so it can better withstand the action of external forces. However, in order to save production costs, some manufacturers use soil to make steel billets to roll rebar, resulting in the rebar strength not meeting the standards and even causing serious construction accidents.

On December 31, 2014, the Ministry of Housing and Urban-Rural Development of China issued an announcement on the national standard "Concrete Structure Engineering Construction Quality Acceptance Specifications", approving the "Concrete Structure Engineering Construction Quality Acceptance Specifications" as the national standard, of which Articles 4.1.2, 5.2.1, 5.2.3, 5.5.1, 6.2.1, 6.3.1, 6.4.2, 7.2.1, and 7.4.1 are mandatory provisions and must be strictly enforced. According to Article 5.2.1 of the "Concrete Structure Engineering Construction Quality Acceptance Specifications": When steel bars enter the site, the test pieces should be extracted for inspection of mechanical properties and weight deviations in accordance with the provisions of the current national standards. The inspection results must comply with the relevant standards of the table, and the inspection quantity shall be determined according to the entry of the quota and the sampling inspection plan of the product. Inspection methods include inspection of product table certificates, factory inspection reports and on-site re-inspection reports.

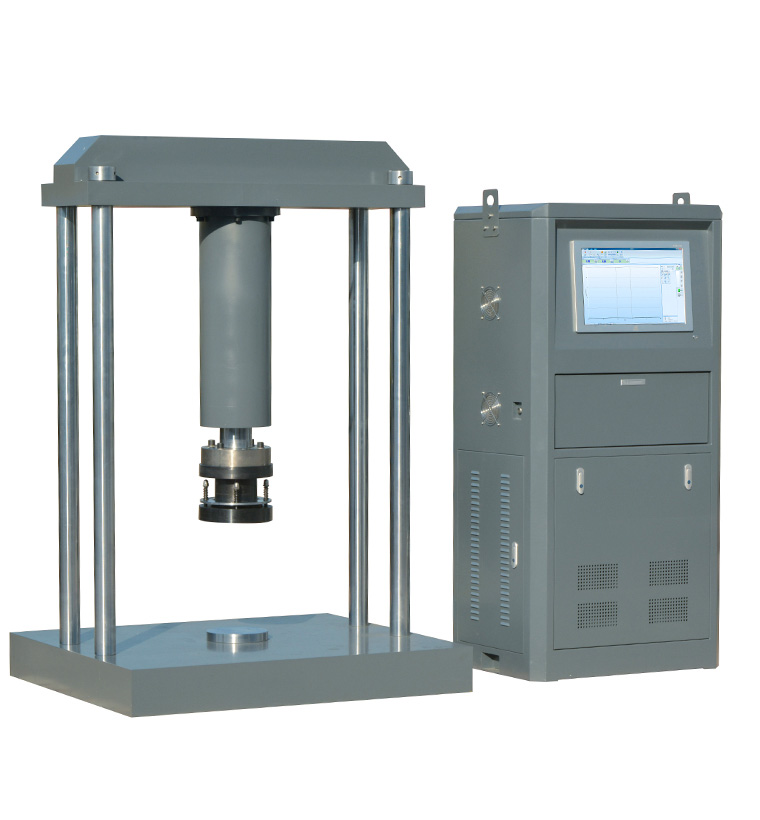

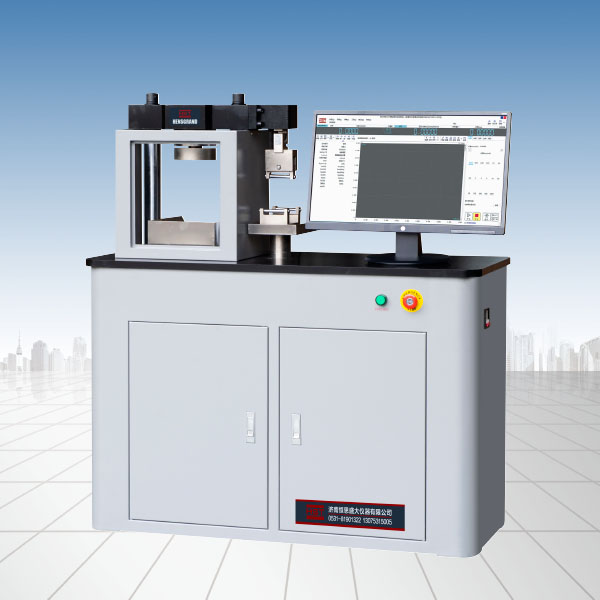

Check the national standard GB/T 1499.2-2018 "Steel for Reinforced Concrete Part 2 Hot Rolled Ribbed Rebars". The mechanical performance testing items of rebar include tensile tests, bending tests, reverse bending tests and fatigue performance tests. As a professional and reliable test machine product supplier, Jinan Hengsi Shanda Instruments can provide a variety of solutions for rebar testing needs.

Recommended productsPRODUCTS