News

Basic knowledge and performance inspection of carbon fiber cloth

Release time:2022-10-14 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

With the rapid development of modern technologies such as aerospace, missiles, atomic energy, automobile industry, and construction engineering, existing steel and alloy materials have been difficult to meet the requirements. Because the carbon fibers developed in recent decades have the advantages of high elastic modulus and high strength, carbon fibers and their composite materials have played a very broad role in various fields of social construction and development.

1. What is carbon fiber cloth

Carbon fiber cloth is also known as carbon fiber cloth, carbon fiber cloth, carbon fiber woven fabric, carbon fiber prepreg cloth, carbon fiber reinforced cloth, carbon fiber fabric, carbon fiber tape, carbon fiber sheet (prepreg cloth), etc. Carbon fiber cloth is a one-way carbon fiber reinforcement product, usually woven with 12K carbon fiber wire, common in two thicknesses: 0.111mm (200g) and 0.167mm (300g), and the width is 100mm, 150mm, 200mm, 300mm, 500mm and other special widths required for projects.

Because of its advantages such as high strength, strong durability, small density, thin thickness, wide application area and convenient construction, carbon fiber cloth is widely used in the reinforcement and repair of various structural types and structural shapes, seismic reinforcement and node structural reinforcement, the principle is to use high-performance carbon fiber cloth to bond it to the surface of concrete components with resin impregnation glue, and use the good tensile strength of carbon fiber material to achieve the purpose of enhancing the bearing capacity and strength of the components. In recent years, with the continuous development of the fiber cloth industry, more and more industries have also used carbon fiber cloth, such as aerospace, sports equipment, industrial manufacturing and fire protection.

two,Carbon fiberclothofClassification

Carbon fiber cloths vary according to their carbon fiber raw silk, specifications, carbonization and weaving methods:

1. Classification by carbon fiber filament

It can be divided into PAN-based carbon fiber cloth (more than 90% of the carbon fiber cloth on the market are this type of carbon fiber cloth), viscose-based carbon fiber cloth and asphalt-based carbon fiber cloth.

2. According to carbon fiber specifications

It can be divided into 1K carbon fiber cloth, 3K carbon fiber cloth, 6K carbon fiber cloth, 12K carbon fiber cloth, 24K and above large tow carbon fiber cloth.

3. According to carbon fiber carbonization

It can be divided into graphitized carbon fiber cloth (can withstand high temperatures of 2000-3000 degrees), carbon fiber cloth (can withstand high temperatures of about 1000 degrees), and pre-oxidized carbon fiber cloth (can withstand high temperatures of 200-300 degrees).

4. According to weaving method

It can be divided into woven carbon fiber cloth (mainly: plain cloth, twill, satin cloth, unidirectional cloth, etc.), knitted carbon fiber cloth (mainly: warp knitted cloth, weft knitted cloth, round machine cloth (casing), horizontal machine cloth (rib cloth), etc.), woven carbon fiber cloth (mainly: sleeve, packing, braiding belt, two-dimensional cloth, three-dimensional cloth, three-dimensional woven cloth, etc.), carbon fiber prepreg cloth (mainly: dry prepreg cloth, wet prepreg cloth, unidirectional prepreg cloth, prepreg belt, no tray, and tray, etc.), carbon fiber non-woven fabric (nonwoven fabric, namely carbon fiber felt, carbon felt, including chopped felt, continuous felt, surface felt, needle felt, sewing felt, etc.).

three,Performance inspection of carbon fiber cloth

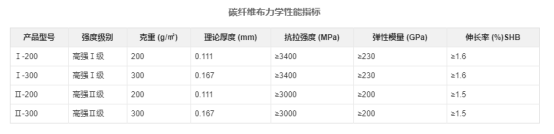

There are many specifications and varieties of carbon fiber cloth, with different properties, excellent heat resistance, semiconductor, electrical conductivity and drug resistance, and mechanical properties are related to the carbon wire used and weaving methods. At present, the most important indicators for measuring the mechanical properties of high-performance carbon fiber cloth are its strength, elastic modulus and elongation of break. With the increase in projects that use adhesion carbon fiber cloth technology for reinforcement, the acceptance of the construction quality of such projects is constantly standardizing. More and more owners are no longer satisfied with the product qualification certificate provided by the construction unit, and are often required to conduct on-site sampling inspection of the carbon fiber cloth and its supporting resins used in the project.

However, it is much more difficult to detect the mechanical properties of carbon fiber cloth than other low-strength fiber materials. It has high requirements for the clamping ability of the end of the sample, the uniform force of the fiber wire, and the neutralization performance of the test machine.

The microcomputer-controlled electronic universal testing machine is mainly used for mechanical properties testing and analysis of metal materials, composite materials, etc. It has three closed-loop control methods: stress, strain, and displacement. It can obtain parameters such as maximum load, tensile strength, bending strength, compression strength, shear strength, elastic modulus, elongation of fracture, yield strength, etc., and can conduct tests and provide data according to national standards and international standards such as ISO, JIS, ASTM, DIN and other international standards.

The main machine of the equipment is a door-type structure, and the middle beam adopts a high-precision guide rod guide, which has high rigidity and good linear motion characteristics. In addition, high and low temperature ambient boxes or high temperature furnaces and related tool fixtures, deformation measurement and other accessories can be configured to meet almost all customer needs. The flexible and easy-to-use HST software provided by the machine makes the user's testing process easier. The experimental solutions cover plastics, metals, automobile industry, building materials, textiles, paper and cardboard, food and packaging, composite materials, etc.

- Previous article:Basic knowledge and performance inspection of rebar

- Next article:Methods for daily maintenance of fatigue testing machines

Recommended productsPRODUCTS