Company News

Analysis of common punch failures in Jinan impact tester

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

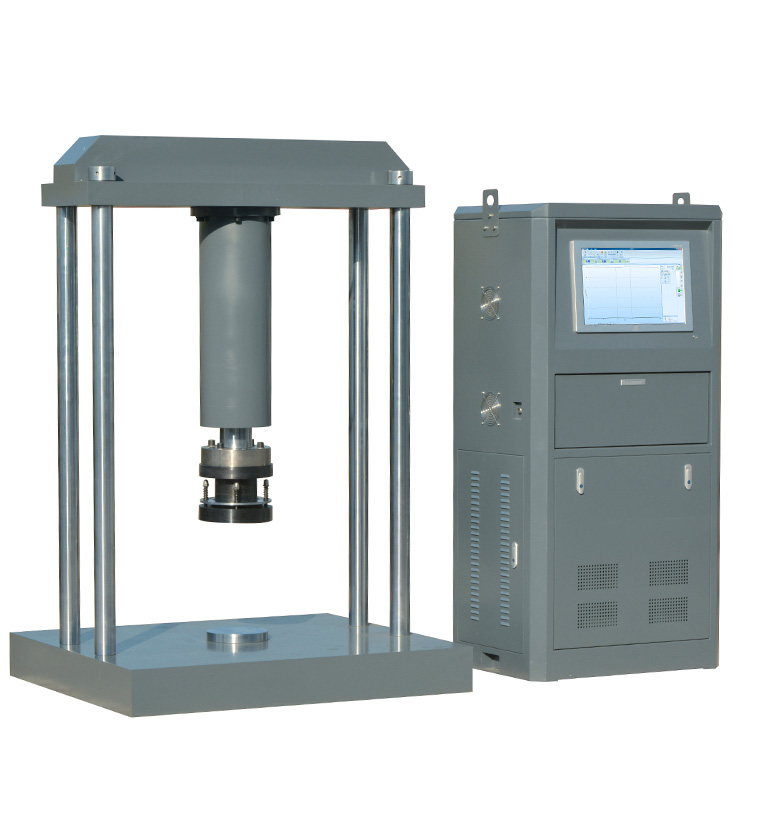

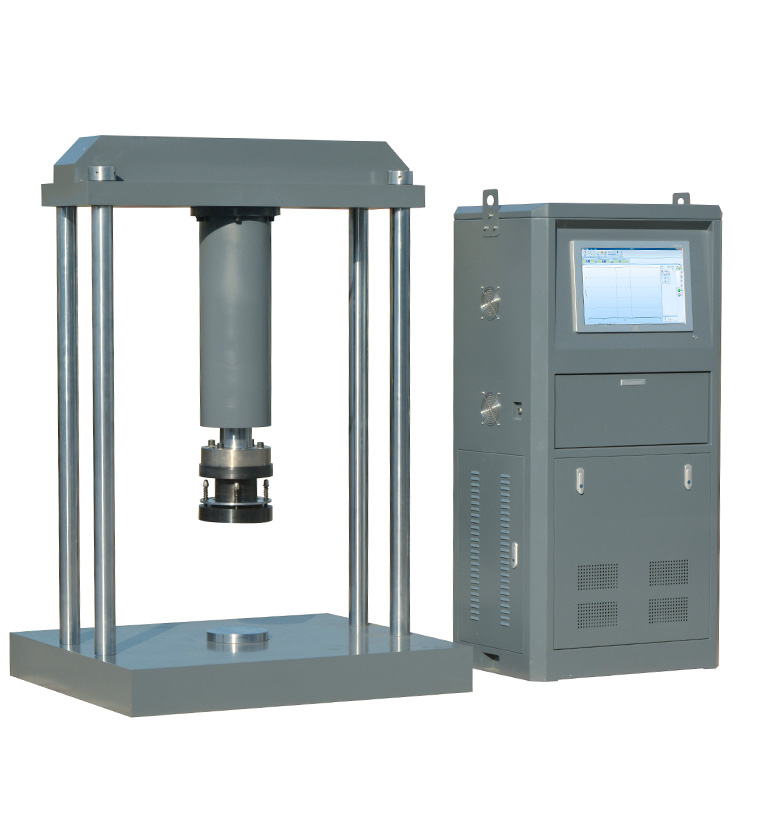

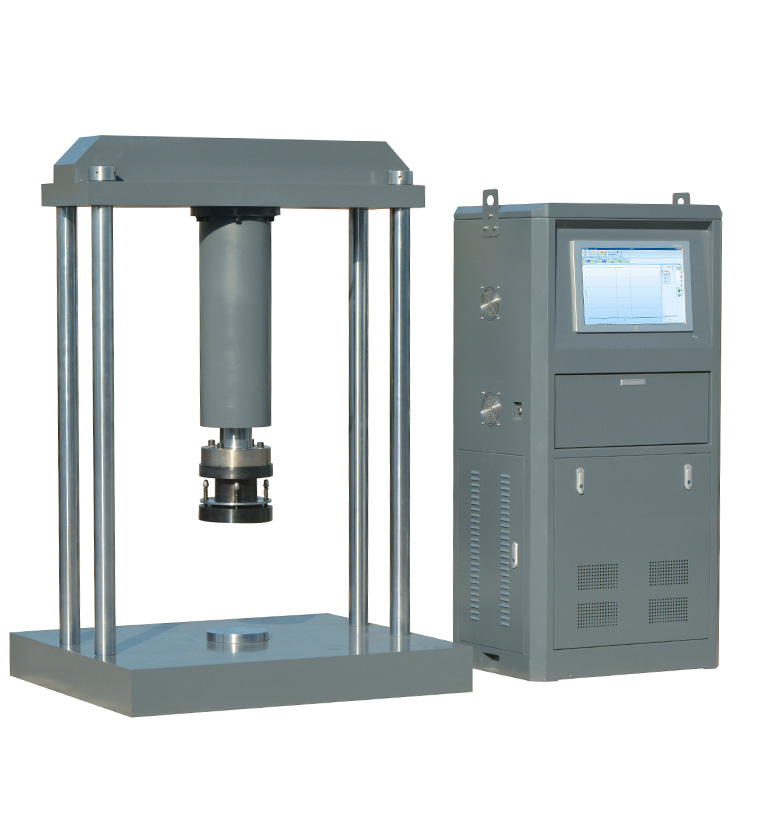

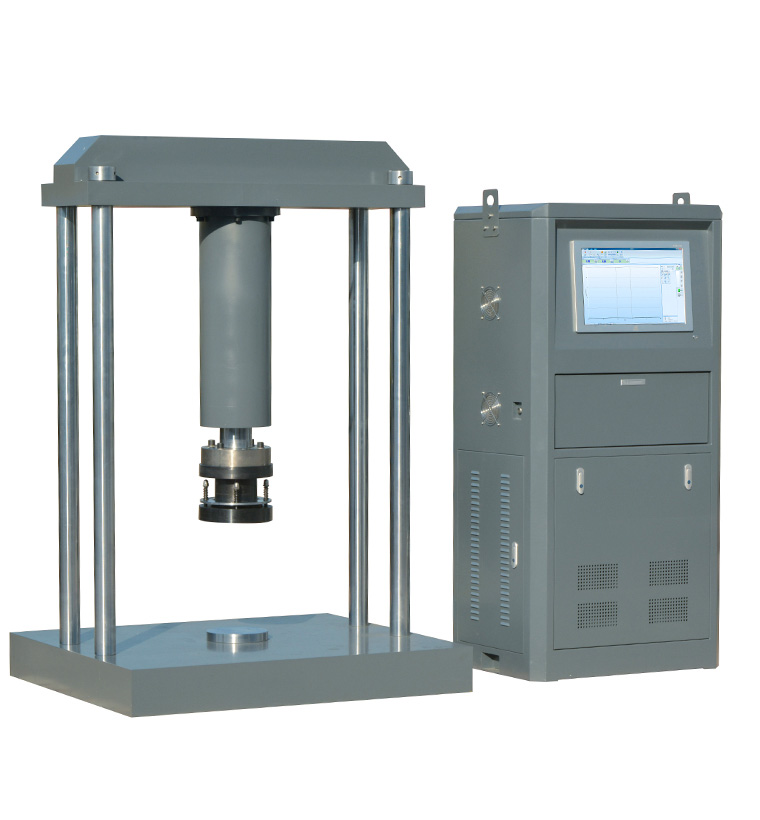

Impact testing machineAs the name suggests, our company analyzes and deals with two common punch failures in impact testing machines:

Fault 1:The punch of the impact tester cannot be released and cannot impact the sample

Possible reasons: The initial height of the rack lock sleeve is not enough, and the hook cannot hook the oblique key, which will cause the punch that impacts the test machine to be unable to be released during startup.

Solution: Remove the handwheel seat, push the rack lock sleeve to the upper limit position, and then tighten the handwheel seat.

Fault 2: Impact TesterPunch continuous impact sample

Possible reasons: The spring force of the spring ring is too large, causing the ball sleeve to not be relatively displaced after the impact ball sleeve is supported, so the punch of the impact tester is always in the release state.

Solution: Manually correct and reduce the opening of the spring swelling ring to appropriately reduce its elasticity.

MoreTesting machineAll information is in Jinan Hengsi Shanda Instrument Co., Ltd.

Tag: Testing Machine, universal testing machine, hydraulic universal testing machine, tensile testing machine, impact tester, Material Torsion Test Machine

Recommended productsPRODUCTS