Company News

Plastic impact test

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Plastic manufacturers all know that plastics are polymer organic materials that are mainly composed of resin, molded into a certain shape at a certain temperature and pressure, and can maintain a certain shape at a certain temperature. Some plastic resins (such as PVC, PP, PS, PC/PBT, etc.) are more sensitive to low-temperature brittleness. Generally, MBS, ASA, CPE, EVA, POEPacrel-ACM and other materials are often used to make certain toughening and impact-resistant modifications to these plastics, making them widely used. How to evaluate the effect of toughening modification requires corresponding impact performance testing and comparison. How to conduct the experiment?

The impact resistance performance experiment is to determine the impact strength of the material under the action of impact load. Impact strength is used to evaluate the ability of a material to resist impact or to judge the degree of brittleness or toughness of a material, which can reflect the ability of different materials to resist damage caused by high-speed impact.

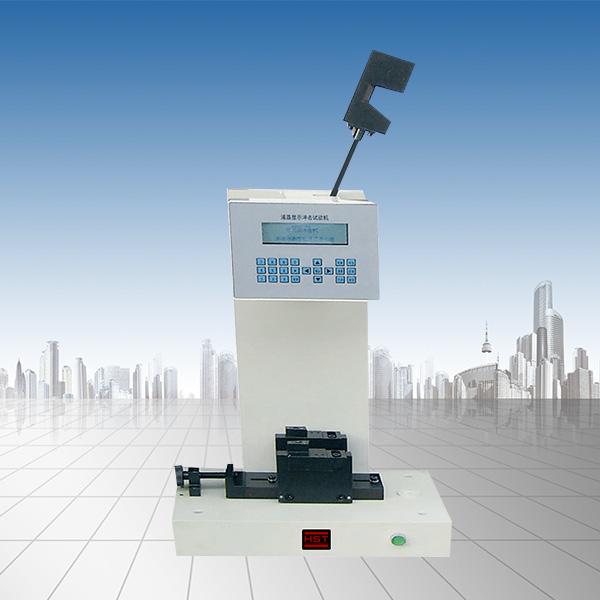

There are many test methods for impact experiments. According to the experimental temperature, it can be divided into normal temperature impact, low temperature impact and high temperature impact; according to the stress state of the sample, it can be divided into bending impact (simplified support beam impact and cantilever beam impact), tensile impact, torsional impact and shear impact; according to the energy and number of impacts used, it can be divided into large-energy one-impact impact (referred to as a single impact experiment or a drop hammer impact experiment) and small-energy multiple-impact experiments. Different impact experiment methods can be selected for different materials or different uses (the same experimental method for the same material is often affected by the experimental temperature, humidity, impact speed, geometry of the sample, and stress mode, etc.), and different impact experiment results will be obtained, and these results cannot be compared horizontally. Therefore, the impact performance experiment cannot obtain fixed parameters that characterize the properties of the material, but it can be characterized by a comparison of the impact toughness of the material under the conditions specified by the experimental method or the impact performance of different materials under the same impact experimental conditions. After purchasing the impact testing machine, the debugger should give the customer a detailed introduction.Impact testing machineThe general test method, impact test is generally divided into 5 steps:

First, measure the test thickness according to GB6672, measure a little at the center of all samples, and take the arithmetic average of 10 samples tests. Then, a punch is selected according to the required pendulum impact energy for the test, so that the reading is between 10% DD90% of the full range. Calibrate the instrument according to the instrument usage rules. Put the sample flat and clamp it in the clamper. The sample should not be wrinkled or the surrounding tension should be too large. The impact surfaces of 10 samples should be consistent. Hang the pendulum on the release device, press the key on the computer to start the test, and let the pendulum impact the sample. The same step is to perform 10 tests. After the test is completed, the arithmetic average of the 10 samples is automatically calculated. This is the entire process of the impact test machine.

- Previous article:Daily maintenance of test machine

- Next article:Test of impact resistance of plastic film

Recommended productsPRODUCTS