Company News

7 daily maintenance of multi-function electronic tension machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

For multifunctional electronicsTension tester, a few points should be paid attention to when maintaining it:

1. Before adding the test piece, the brake handle must be stuck, and then release it after adding the test piece.

2. Before starting the test machine, check whether lubricating oil should be added to the frictional moving parts.

3. The oil used for the buffer should be kept clean. If the oil level is less than two-thirds of the depth of the cylinder, it should be replaced immediately.

4.Testing machineBefore the test, the system must be preheated for more than 20 minutes, so that the temperature drift has little impact.

5. After the test is completed, after the power is cut off, the test machine will be cleaned and protected in a timely manner.

6. Refueling is not allowed on the main bearing of the dynamometer. The surface of the friction wheel in the gearbox must not be refueled or oil stains splashed. The friction surface should be clean and the inclined block on the swing arm must not be violently impacted.

7. The tensioner is maintained twice a month on average.

The above are some technical standards summarized by the manufacturer, more aboutTesting machineDetailed information is available in Jinan Hengsi Shanda Instrument Co., Ltd.

- Previous article:Detailed explanation of the 10-step process of steel strand tensile test

- Next article:5 steps of daily maintenance of test machine

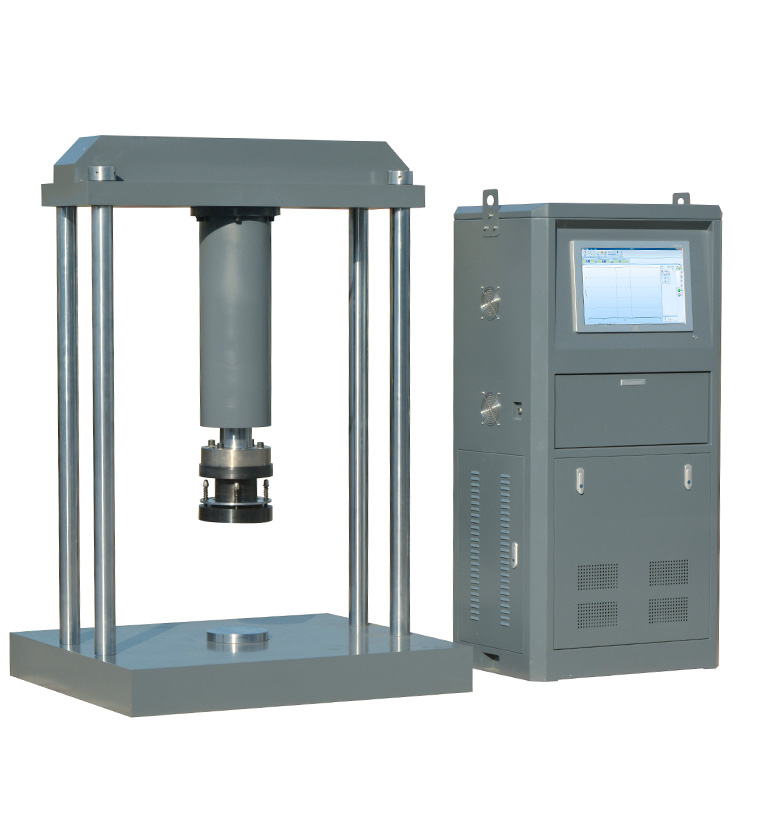

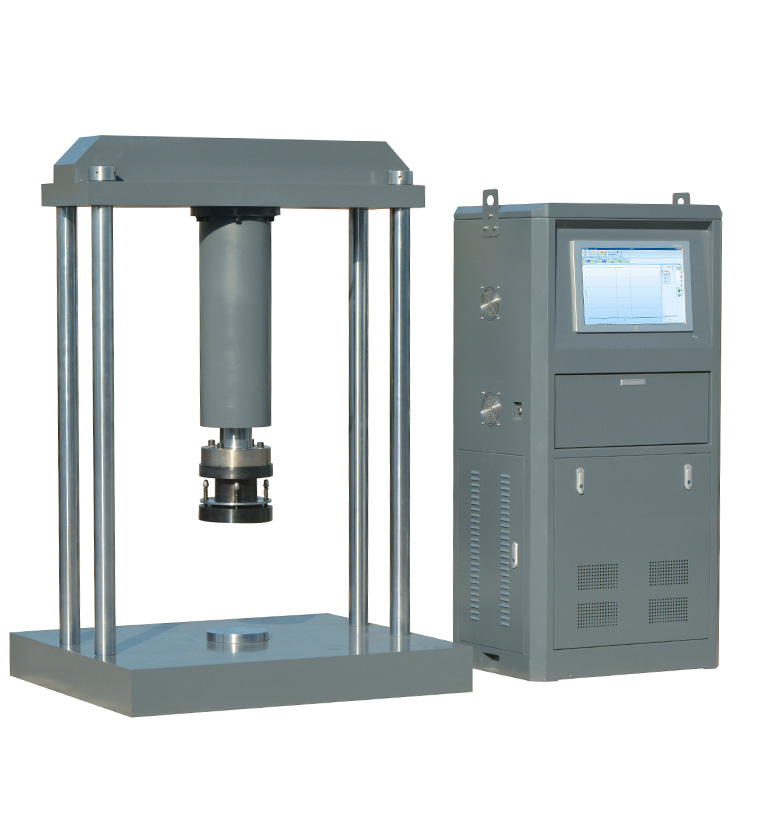

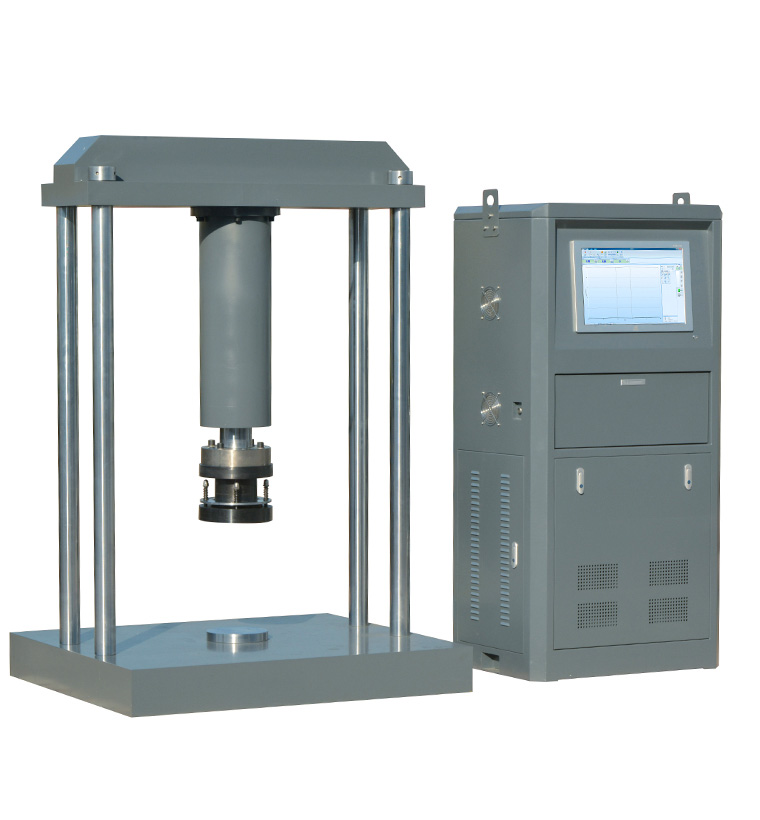

Recommended productsPRODUCTS